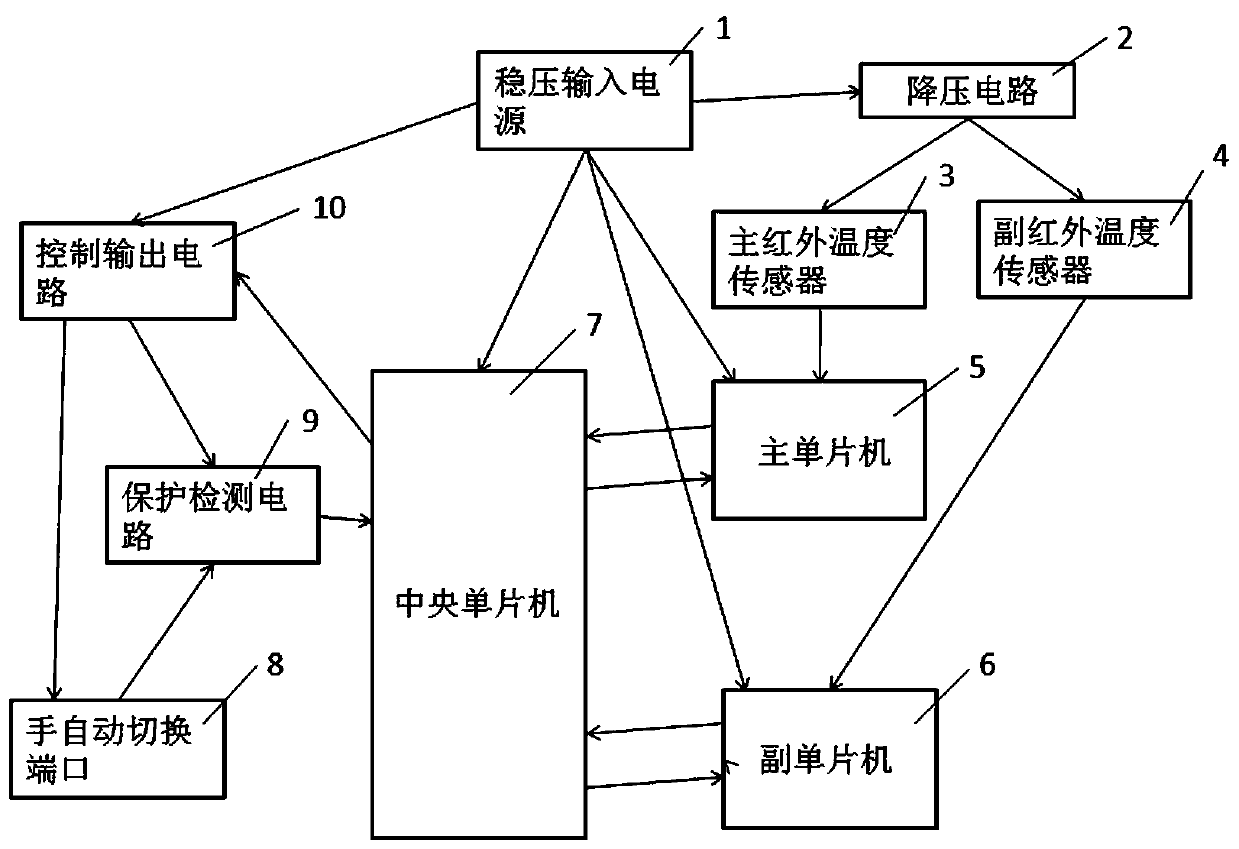

Method and control system for automatically controlling range hood through infrared temperature induction

A range hood, infrared temperature technology, applied in the direction of removing oil fume, application, heating method, etc., can solve the problems of reduced outlet sensitivity, difficulty in cleaning gas sensor, shortened service life, etc., and achieves high safety and high adjustability. , the effect of a large detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

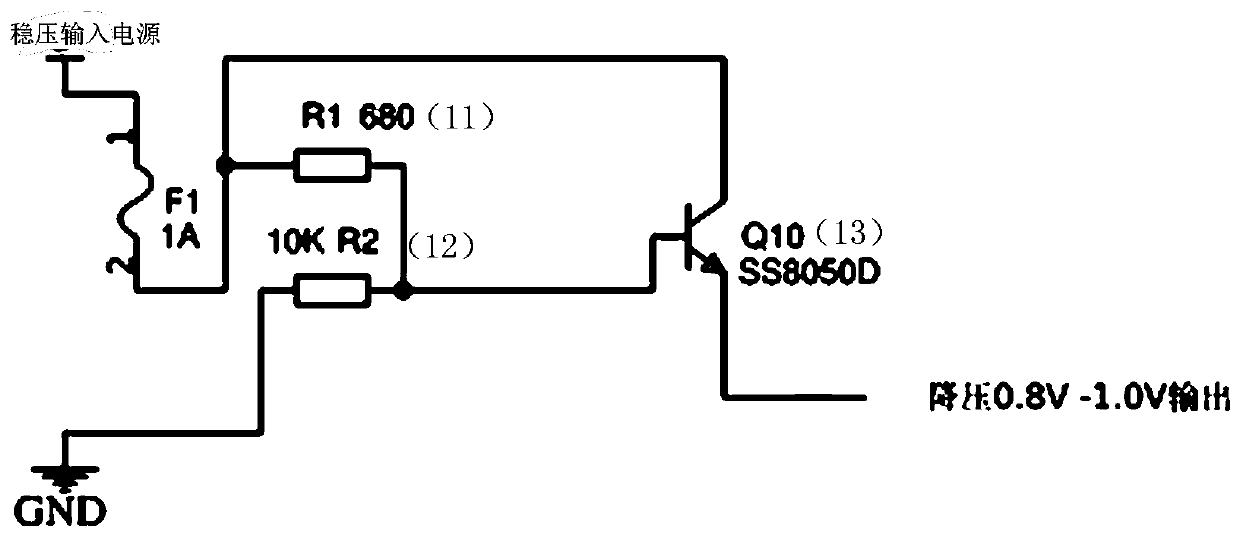

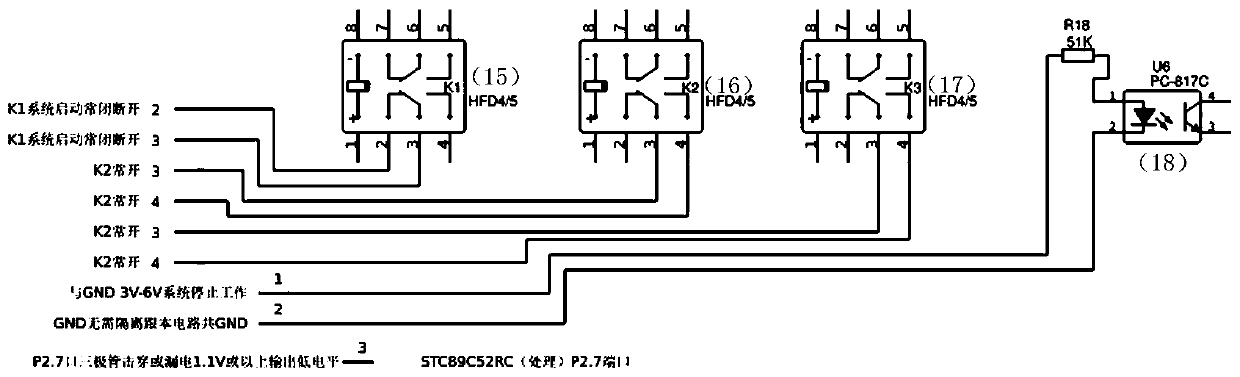

[0034] The method for automatic control of the range hood by infrared temperature sensing in the present invention: real-time detection of the temperature rise of the gas stove, segmented cycle processing through the single-chip microcomputer chip, firstly save the temperature rise value read in real time in the previous section, and then save the temperature rise value of the next section A re-read real-time temperature rise value will be compared with the temperature rise value read in the previous stage to form a cycle, and the opening and speed regulation of the range hood will be controlled according to the number of times the temperature rise value reaches the program setting value within the set time period ,closure.

[0035] The basic logic of the control is: when the number of times the temperature rise value reaches the minimum value of the minimum temperature rise value of each segment data in the real-time segment processing within the set time period is greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com