Indirect hot blast stove

A hot blast stove, indirect technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of narrow air passage of indirect hot blast stoves, small outlet hot air flow, insufficient heat exchange, etc., to achieve Simple structure, improved heat exchange efficiency, and guaranteed heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but this application does not limit the protection scope of the claims of this application.

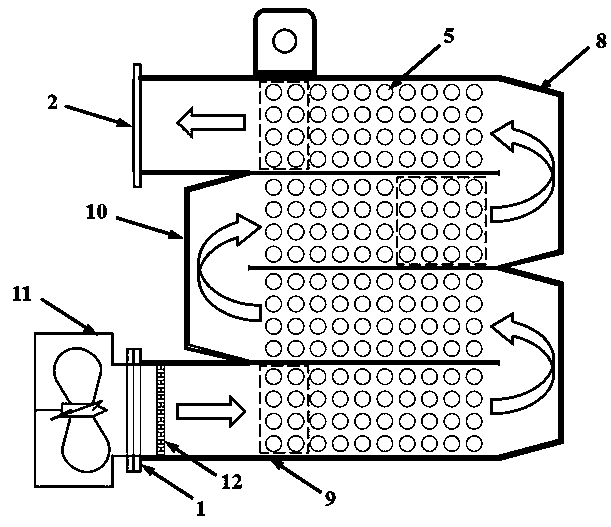

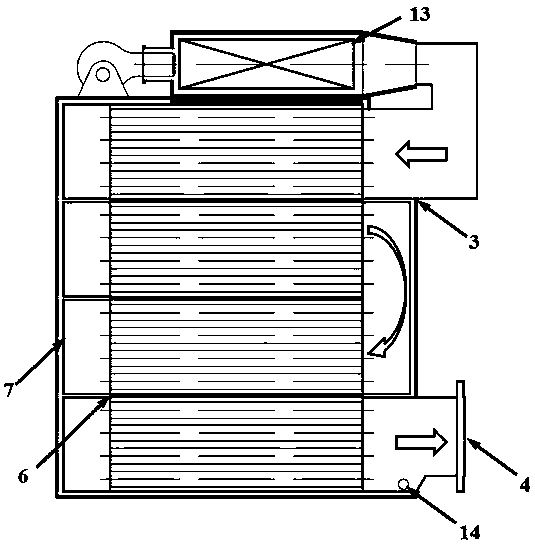

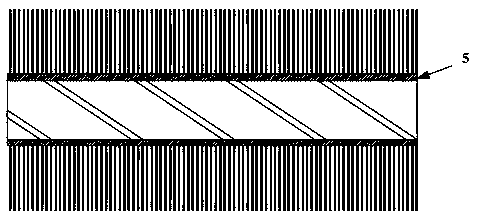

[0020] The indirect hot blast stove designed by the present invention (abbreviation hot blast stove, see Figure 1-2 ) is rectangular in shape. It is characterized in that: a cold air (cold air) inlet 1 is provided at the bottom of the cuboid shell, and the cold air inlet 1 is a rectangular channel, welded to the wall of the heat exchange chamber 9, the width is consistent with the welding surface of the heat exchange chamber, and the height accounts for about 1 / 4 of the welding surface. Extend a certain distance from the cold air inlet 1 to the heat exchange chamber to install a thin layer of dehumidification filter device 12, extending from the heat exchange chamber 9 to the outside of the insulation layer 10; the cold air is blown into the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com