Nitrogen-containing high-entropy alloy composite material and preparation method thereof

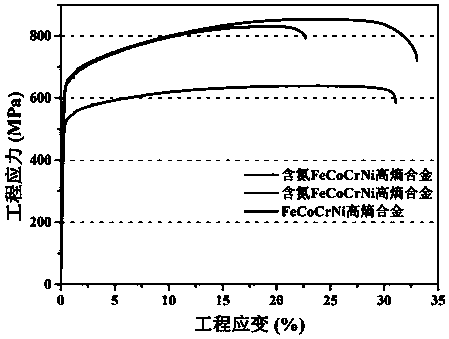

A high-entropy alloy and composite material technology, which is applied in the field of nitrogen-containing high-entropy alloy composite materials and its preparation, can solve the problem that the nitriding of the coating is difficult to uniformize the structure, so as to overcome the poor creep performance and fatigue resistance and improve the Yield strength and ultimate strength, and the effect of improving fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

[0045] The invention provides a method for preparing a nitrogen-containing high-entropy alloy composite material, comprising the following steps:

[0046] (1) Fe, Co, Cr, and Ni metal elements are selected as raw materials, and the atomic ratio of Fe, Cr, Ni, Co, and N in the composite material is 1:1:1:1:0.07, and the high-entropy material is prepared by gas atomization. Pre-alloyed powder, using nitrogen as the protective atmosphere; wherein, the alloying element powder does not contain other impurities except a small amount of unavoidable impurity oxygen, and the raw material does not contain other elements except Fe, Co, Cr, Ni, N; The particle size range of high-entropy pre-alloyed powder is 15-55 μm, and the D50 is controlled at 40 μm;

[0047] (2) Establish a three-dimensional model of the part on the computer, plan the scanning path of the component, and scan using a checkerboard pattern layer by layer; when scanning layer by layer, the deflection angle is 65°;

[004...

Embodiment 2

[0055] The invention provides a method for preparing a nitrogen-containing high-entropy alloy composite material, comprising the following steps:

[0056] (1) Fe, Co, Cr, and Ni metal elements are selected as raw materials, and the atomic ratio of Fe, Cr, Ni, Co, and N in the composite material is 1:1:1:1:0.08, and the high-entropy material is prepared by gas atomization. Pre-alloyed powder, using nitrogen as the protective atmosphere; wherein, the alloying element powder does not contain other impurities except a small amount of unavoidable impurity oxygen, and the raw material does not contain other elements except Fe, Co, Cr, Ni, N; The particle size range of high-entropy pre-alloyed powder is 15-45 μm, of which D50 is controlled at 40 μm;

[0057] (2) Establish a three-dimensional model of the part on the computer, plan the scanning path of the component, and scan using a checkerboard pattern layer by layer; when scanning layer by layer, the deflection angle is 70°;

[00...

Embodiment 3

[0064] The invention provides a method for preparing a nitrogen-containing high-entropy alloy composite material, comprising the following steps:

[0065] (1) Fe, Co, Cr, Ni, Mn metal elements are selected as raw materials, and the atomic ratio of Fe, Cr, Ni, Co, Mn, N in the composite material is 1:1:1:1:1:1:0.07. The high-entropy pre-alloyed powder is prepared by the atomization method, and nitrogen is used as the protective atmosphere; among them, the alloy element powder does not contain other impurities except a small amount of unavoidable impurity oxygen, and the raw material does not contain Fe, Co, Cr, Ni, Mn , Other elemental components other than N; the particle size range of high-entropy pre-alloyed powder is 15-45 μm, of which D50 is controlled at 40 μm;

[0066] (2) Establish a three-dimensional model of the part on the computer, plan the scanning path of the component, and scan using a checkerboard pattern layer by layer; when scanning layer by layer, the deflect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com