Preparation method of laminar carbon nano tube enhanced copper-based composite material

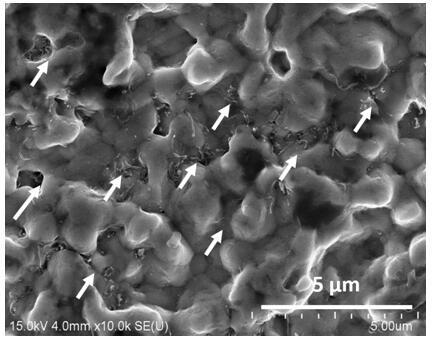

A copper-based composite material, carbon nanotube technology, applied in coatings, electrolytic coatings, etc., can solve problems such as strength sacrifice, achieve the effects of delayed initiation, simple equipment, and reduced crack growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

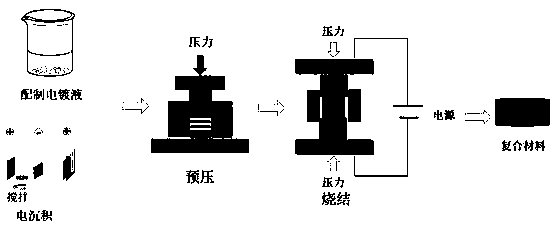

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of electroplating solution: take 160 g of CuSO 4 ·5H 2 O, 10 g of carbon nanotube dispersion, 25 ml of H 2 SO 4 (commercially available concentrated sulfuric acid) was added to ultrapure water to make up to 1000 ml, and the prepared solution was stirred on a magnetic stirrer for 15 minutes.

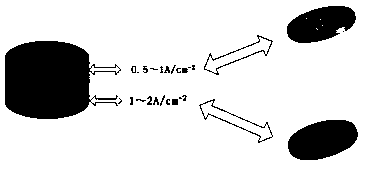

[0021] (2) Preparation of composite film: Pour the prepared solution into the electroplating tank, use two copper plates as anodes, and place a titanium plate as a cathode in the electroplating tank, and connect it to a DC power supply; first use 1 A · dm -2 Electroplating at the current density, after 30 minutes of electroplating, change the current density to 1.5 A dm -2 Continue electroplating, and then change the current density to 1A dm after electroplating for half an hour -2 , repeated 8 times; the titanium plate after electroplating was taken out and placed in a vacuum drying oven for drying at a drying temperature of 65°C. After drying for 5 hours, the...

Embodiment 2

[0026] (1) Preparation of electroplating solution: take 160 g of CuSO 4 ·5H 2 O, 10 g of carbon nanotube dispersion, 25 ml of H 2 SO 4 (commercially available concentrated sulfuric acid) was added to the volume of ultrapure water to 1000 ml, and the prepared solution was stirred on a magnetic stirrer for 15 minutes.

[0027] (2) Preparation of composite film: Pour the prepared solution into the electroplating tank, use two copper plates as anodes, and one titanium plate as a cathode, place them in the electroplating tank, and connect to a DC power supply. First use 0.5 A·dm -2 Electroplating at current density, after electroplating for 60 minutes, change the current density to 1A dm -2 Continue electroplating, and then change the current density to 0.5A·dm after electroplating for 60 minutes -2 , repeated 9 times; the titanium plate after electroplating was taken out and placed in a vacuum drying oven for drying at a drying temperature of 65°C. After drying for 5 hours, t...

Embodiment 3

[0032] (1) Preparation of electroplating solution: take 160 g of CuSO 4 ·5H 2 O, 10 g of carbon nanotube dispersion, 25 ml H 2 SO 4 (commercially available concentrated sulfuric acid) was added to the volume of ultrapure water to 1000 ml, and the prepared solution was stirred on a magnetic stirrer for 15 minutes.

[0033] (2) Preparation of composite film: Pour the prepared solution into the electroplating tank, use two copper plates as anodes, and one titanium plate as a cathode, place them in the electroplating tank, and connect to a DC power supply. First use 0.8A·dm -2 Electroplating at the current density, after 10 minutes of electroplating, change the current density to 2 A dm -2 Continue electroplating, and then change the current density to 1.5A dm after electroplating for 10 minutes -2 , repeated 10 times. The titanium plate after electroplating is taken out and placed in a vacuum drying oven for drying at a drying temperature of 65°C. After drying for 5 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com