High-elasticity corrosion-resistant styrene-butadiene rubber composite material and preparation method thereof

A technology of styrene-butadiene rubber and composite materials, which is applied in the field of polymer materials, can solve the problems of poor performance, adverse effects of normal use and storage of products, and high corrosion, so as to achieve improved compatibility, excellent mechanical properties and seawater resistance Corrosion, the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

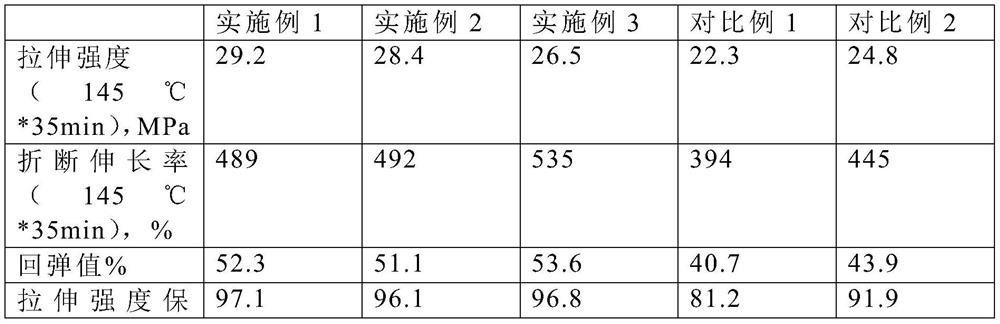

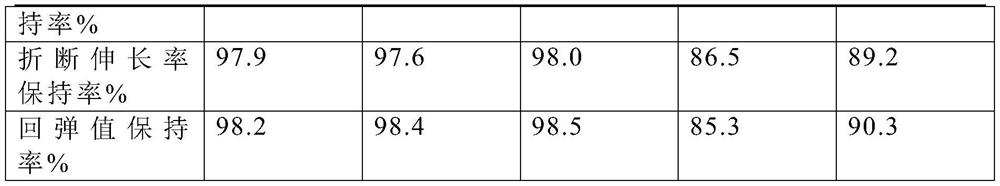

Examples

Embodiment 1

[0043] The styrene-butadiene rubber composite material of the present embodiment comprises the following components by weight:

[0044] Styrene butadiene rubber SBR1502: 75 parts,

[0045] Carbon fiber HTA40: 15 parts,

[0046] C5 petroleum resin: 6 parts,

[0047] Accelerator DM: 1 part,

[0048] BP-6: 0.5 parts,

[0049] UV-326: 0.5 parts,

[0050] Vulcanizing agent DCP: 1 part,

[0052] Stearic acid: 1 part.

[0053] The preparation method comprises the following steps:

[0054] (1) Dissolve C5 petroleum resin in toluene to obtain C5 petroleum resin glue; dissolve styrene-butadiene rubber SBR1502 in toluene at 50°C to obtain styrene-butadiene rubber glue; disperse carbon fiber HTA40 in toluene and stir Under conditions, add C5 petroleum resin glue, after stirring for 2 hours, then add styrene-butadiene rubber glue, after stirring for 4 hours, a mixed solution is obtained;

[0055] (2) Heating the mixed liquid oil bath to above the boil...

Embodiment 2

[0058] The styrene-butadiene rubber composite material of the present embodiment comprises the following components by weight:

[0059] Styrene butadiene rubber SBR1502: 85 parts,

[0060] Glass fiber T635B: 20 parts,

[0061] C5 hydrogenated petroleum resin: 10 parts,

[0062] Accelerator CZ: 1.5 parts,

[0063] BP-3: 1 part,

[0064] UV-327: 0.5 parts,

[0065] Vulcanizing agent TAIC: 1.5 parts,

[0067] Stearic acid: 2 parts.

[0068] The preparation method comprises the following steps:

[0069] (1) Dissolve C5 hydrogenated petroleum resin in toluene to obtain C5 hydrogenated petroleum resin glue; dissolve styrene-butadiene rubber SBR1502 in toluene at 45°C to obtain styrene-butadiene rubber glue; disperse glass fiber T635B in In toluene, under stirring conditions, add C5 hydrogenated petroleum resin glue, after stirring for 3 hours, then add styrene-butadiene rubber glue, after stirring for 3 hours, a mixed solution is obtained;

...

Embodiment 3

[0073] The styrene-butadiene rubber composite material of the present embodiment comprises the following components by weight:

[0074] Styrene butadiene rubber SBR1500: 90 parts,

[0075] Glass fiber T635B: 30 parts,

[0076] C5 petroleum resin: 12 parts,

[0077] Accelerator TETD: 2 parts,

[0078] BP-4: 1 part,

[0079] UV-P: 1 part,

[0080] Vulcanizing agent TAIC: 2 parts,

[0081] Zinc oxide: 4 parts,

[0082] Stearic acid: 3 parts.

[0083] The preparation method comprises the following steps:

[0084] (1) Dissolve C5 petroleum resin in xylene to obtain C5 petroleum resin glue; dissolve styrene-butadiene rubber SBR1500 in xylene at 55°C to obtain styrene-butadiene rubber glue; disperse glass fiber T635B in xylene , under stirring conditions, add C5 petroleum resin glue, after stirring for 4 hours, then add styrene-butadiene rubber glue, after stirring for 2 hours, a mixed solution is obtained;

[0085] (2) heating the mixed liquid oil bath to above the boiling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com