Micro gripper with biomimetic superhydrophobic structure and method for making its jaw end face

A micro-clamping and super-hydrophobic technology, applied in workpiece clamping devices, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

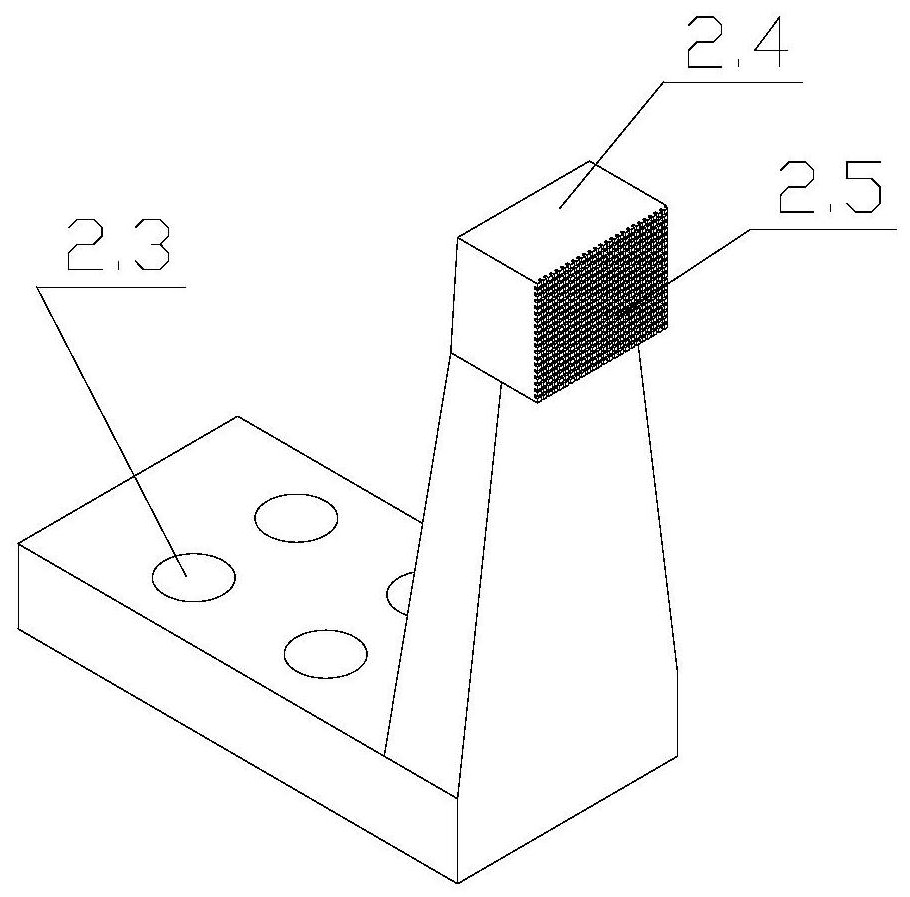

[0036] The micro gripper with biomimetic superhydrophobic structure and the manufacturing method of the jaw end face thereof of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0037] The micro-gripper with bionic super-hydrophobic structure of the present invention imitates the microstructure of the surface of animals and plants, and uses laser to perform bionic microstructure processing on the end face of the clamp end of the micro-gripper, so that the surface has special wettability, reaching Super-hydrophobic, so as to improve the coefficient of friction at the end of the micro-gripper clamp, reduce adhesion, and have self-cleaning, anti-corrosion, anti-icing, anti-frost and other properties.

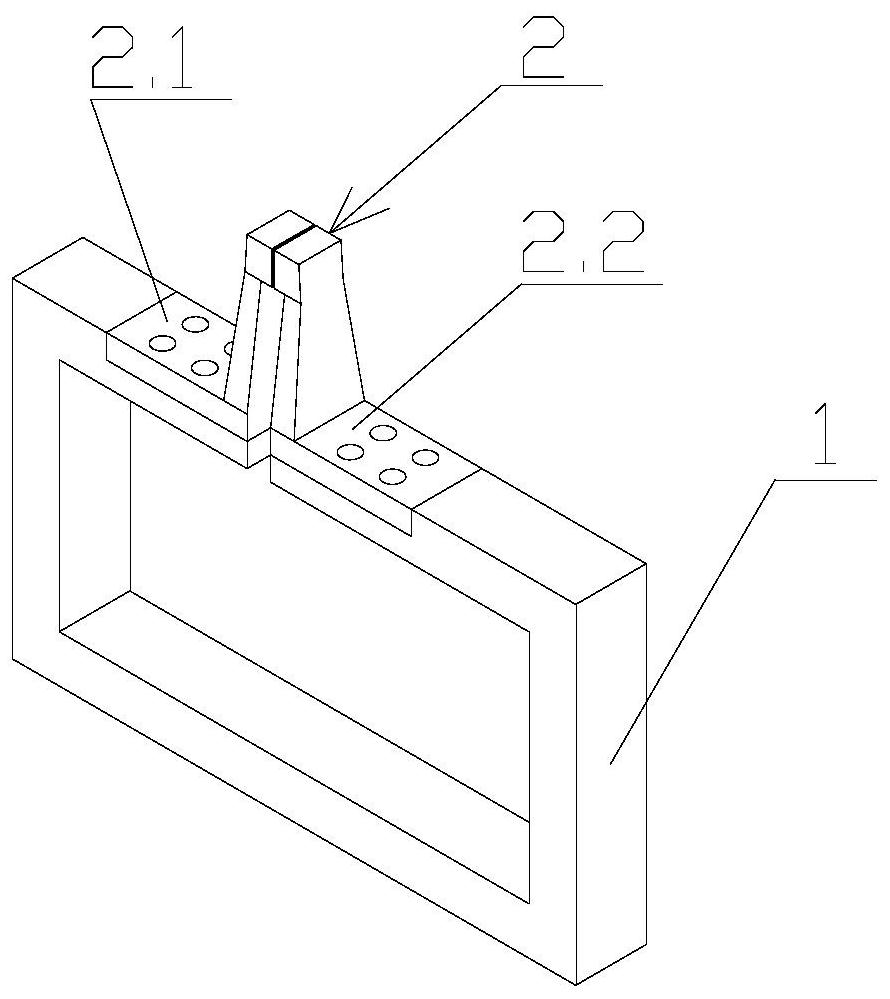

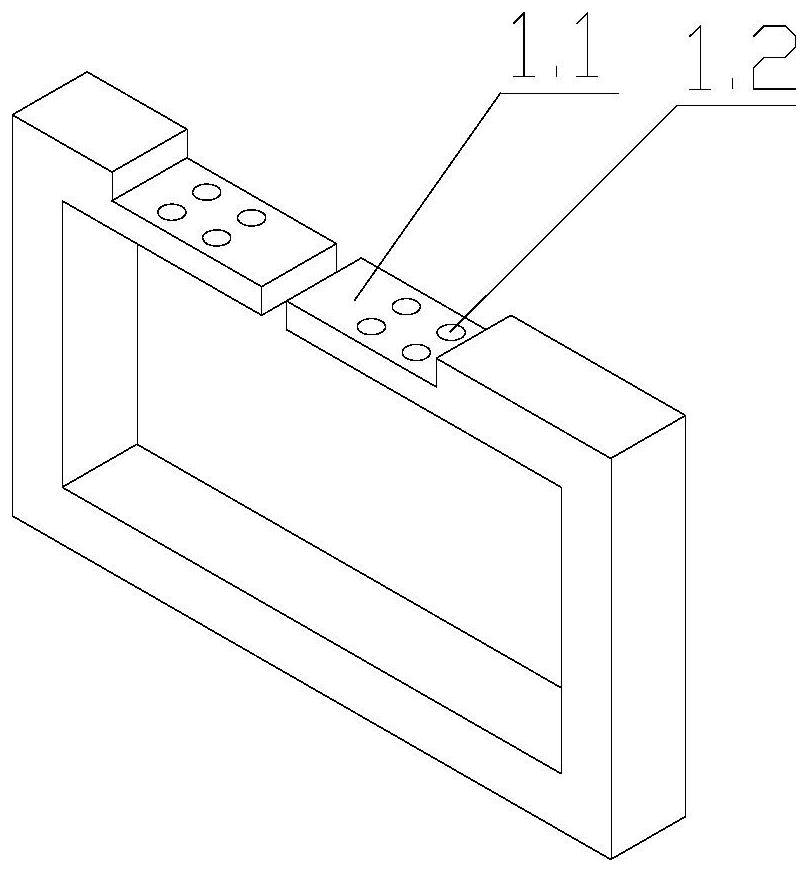

[0038] like figure 1 As shown, the micro-gripper with bionic superhydrophobic structure of the present invention includes a base 1 and a clamp 2 connected to the base 1, and the clamp 2 is composed of a left cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com