Profile modeling prefabricated part puncture method

A prefabricated part and reverse direction technology, which is applied in the field of aerospace prefabricated parts preparation, can solve the problem of low puncture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

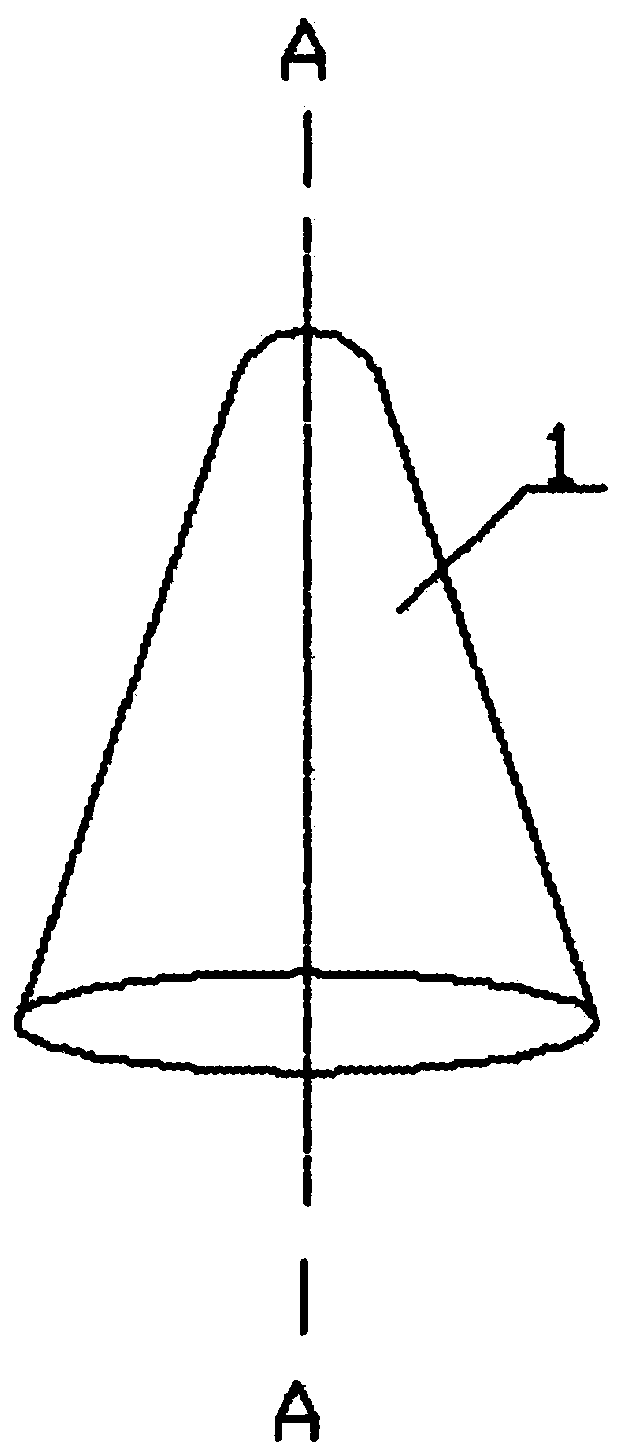

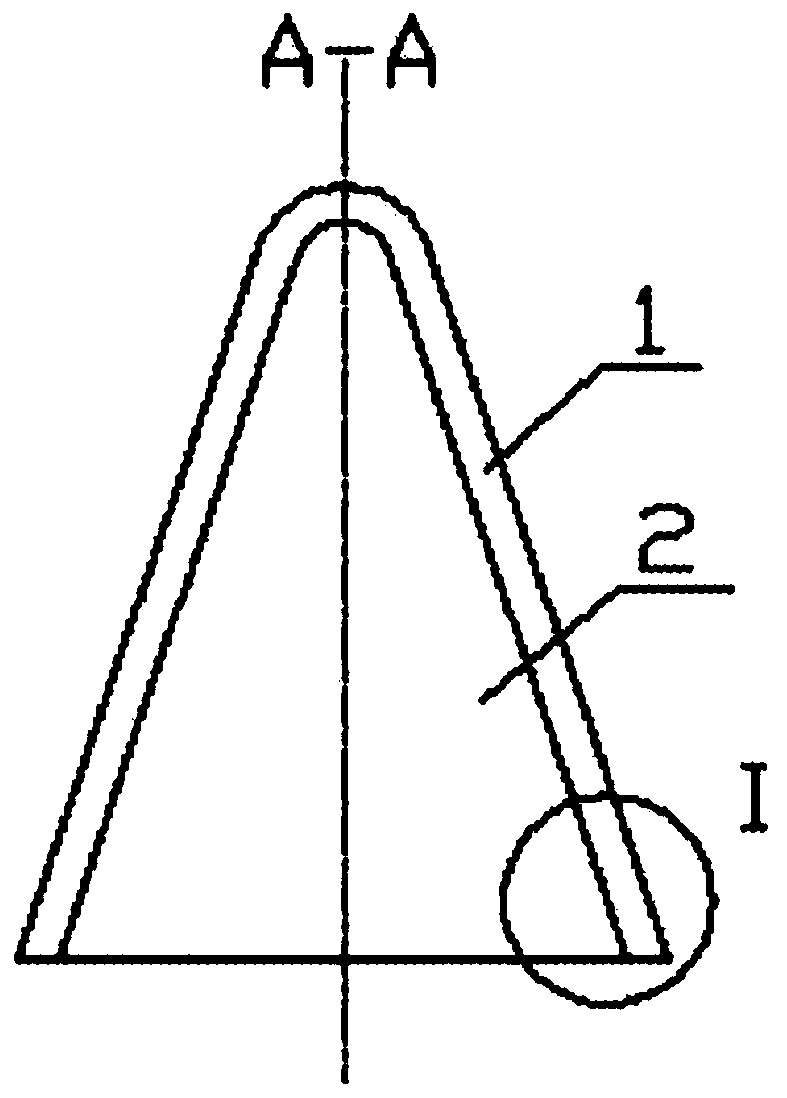

[0021] as attached figure 1 Shown, a kind of profiling preform 1 piercing method comprises the following steps:

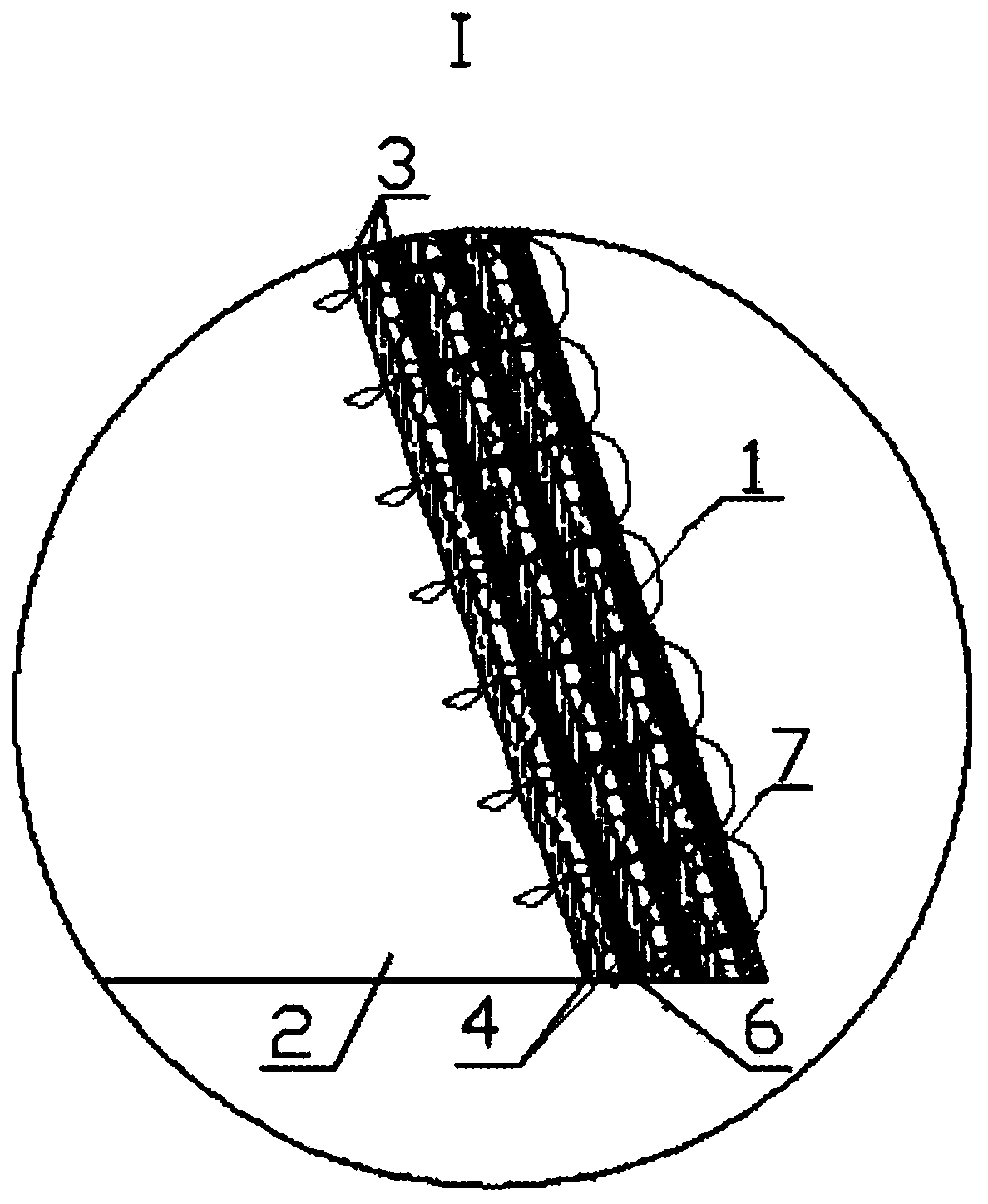

[0022] S1, wrapping the multi-layer fiber cloth 4 on the mold 2, and sewing the multi-layer fiber cloth along the joint of the fiber cloth to form a laminated unit 3;

[0023] Generally, a three-layer fiber cloth layer 4 is used as a laminated unit 3; the fiber cloth here is formed by weaving longitudinally and horizontally with warp fibers and weft fibers. The size of the fiber cloth is selected according to the raw materials used, and the fiber cloth is laid along the outer surface of the mold. Or wrap multiple layers around the mold, a piece of fiber cloth can wrap 1 to 3 layers around the mold, or any non-integer layer, and the laying of a laminated unit is completed by laying multiple pieces of fiber cloth multiple times.

[0024] When laying multiple times, the multi-layer fiber cloth is wrapped on the mold, and each layer of fiber cloth can be sewed along t...

Embodiment 2

[0039] Preferably, the step S2 of repeating the above step S1 to form a plurality of laminated units, and sewing all the laminated units to form a semi-finished product includes:

[0040] S21A wrapping three layers of fiber cloth on the lamination unit, and the joints of the fiber cloth are interlaced with each other during the wrapping process;

[0041] S22A Sew three layers of fiber and all layers of fiber cloth of the previous stacked unit along the joint position of the fiber cloth to complete the stitching of two adjacent stacked units;

[0042] S23A repeats the above wrapping step S21A and sewing step S22A, and sequentially completes the sewing of two adjacent stacked units from the inside to the outside; here, the inside refers to the direction close to the mold, and the outside refers to the direction away from the mold;

[0043] After S24A is demolded, all laminated units are stitched through to form a semi-finished product.

[0044] In this scheme, the first stackin...

Embodiment 3

[0046] Preferably, the step S2 of repeating the above step S1 to form a plurality of laminated units, and sewing all the laminated units to form a semi-finished product further includes:

[0047] S21B wrapping two layers of fiber cloth on the lamination unit, and the joints of the fiber cloth are interlaced with each other during the wrapping process;

[0048] S22B sets a fiber net sleeve on two layers of fiber cloth;

[0049] S23B Sew two layers of fiber, fiber net cover layer and upper layer of unit cloth along the joint position of fiber cloth to complete the stitching of adjacent two layers of units;

[0050] S24B repeats the above wrapping steps S21B, S22B and sewing step S23B, and sequentially completes the sewing of two adjacent stacked units from inside to outside;

[0051] After the S25B is demoulded, all laminated units are stitched through to form a semi-finished product.

[0052] In this scheme, the first stacking unit, the second stacking unit, the third stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com