Overall heat management system for electric tractor and control method of system

A heat management system and management system technology, applied in the field of electric tractor heat management system and its control, can solve the problems of increasing the continuous operation time of the tractor, the low heat dissipation efficiency of the power battery, and the unreasonable use of the heat of the motor, etc., and achieve improvement Continuous operating time, efficient thermal management, and waste-free effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

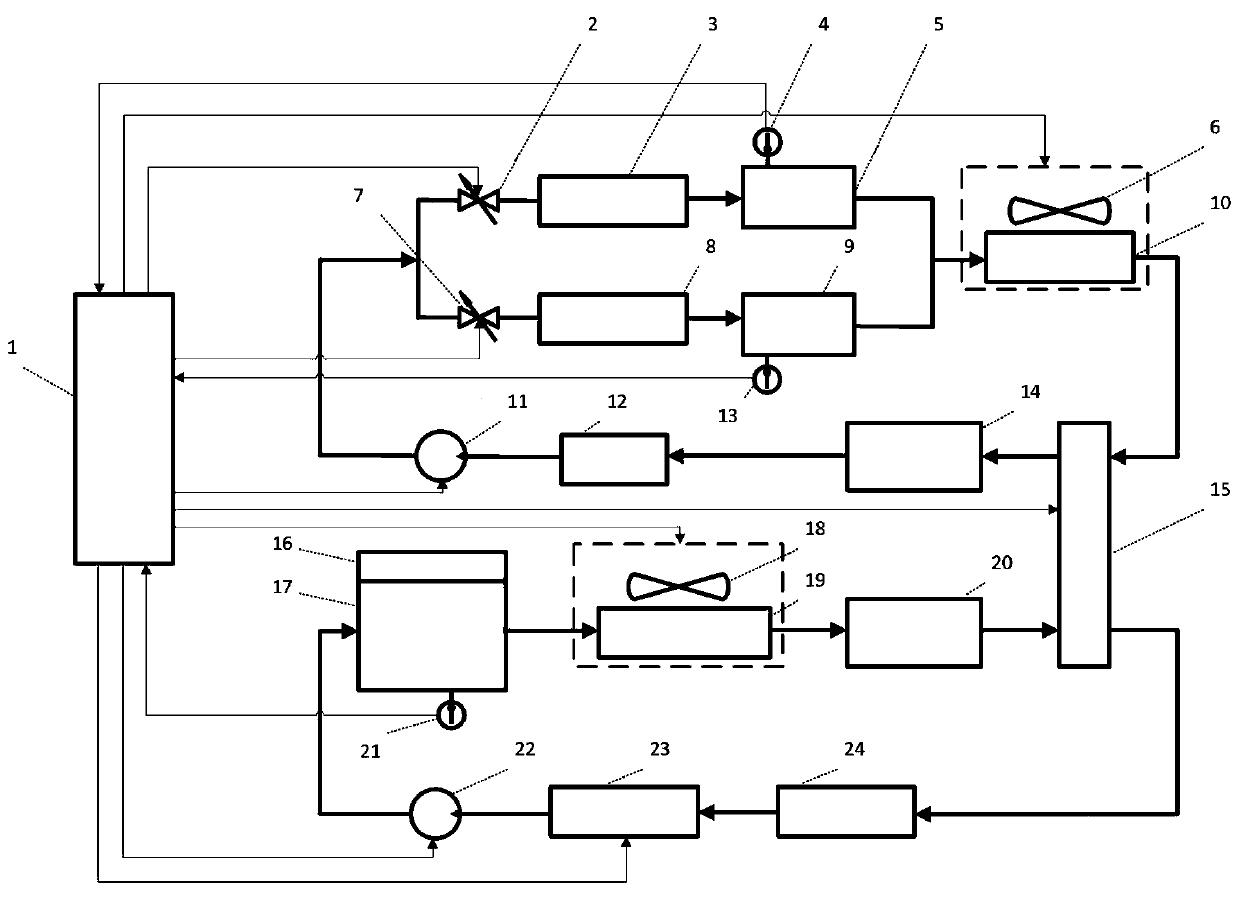

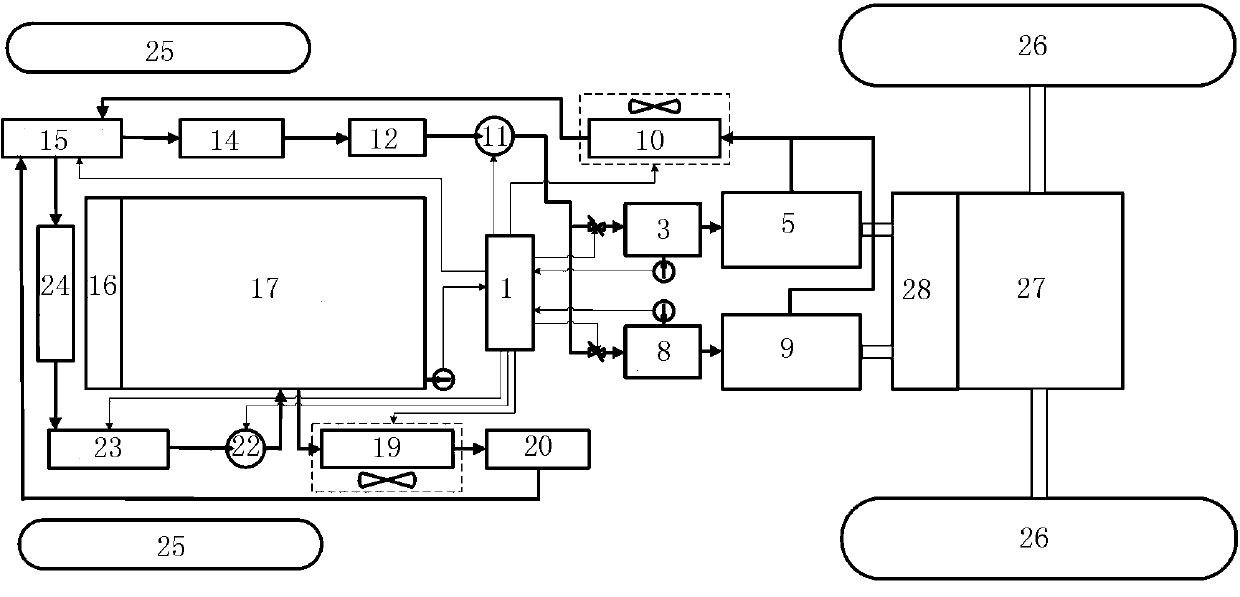

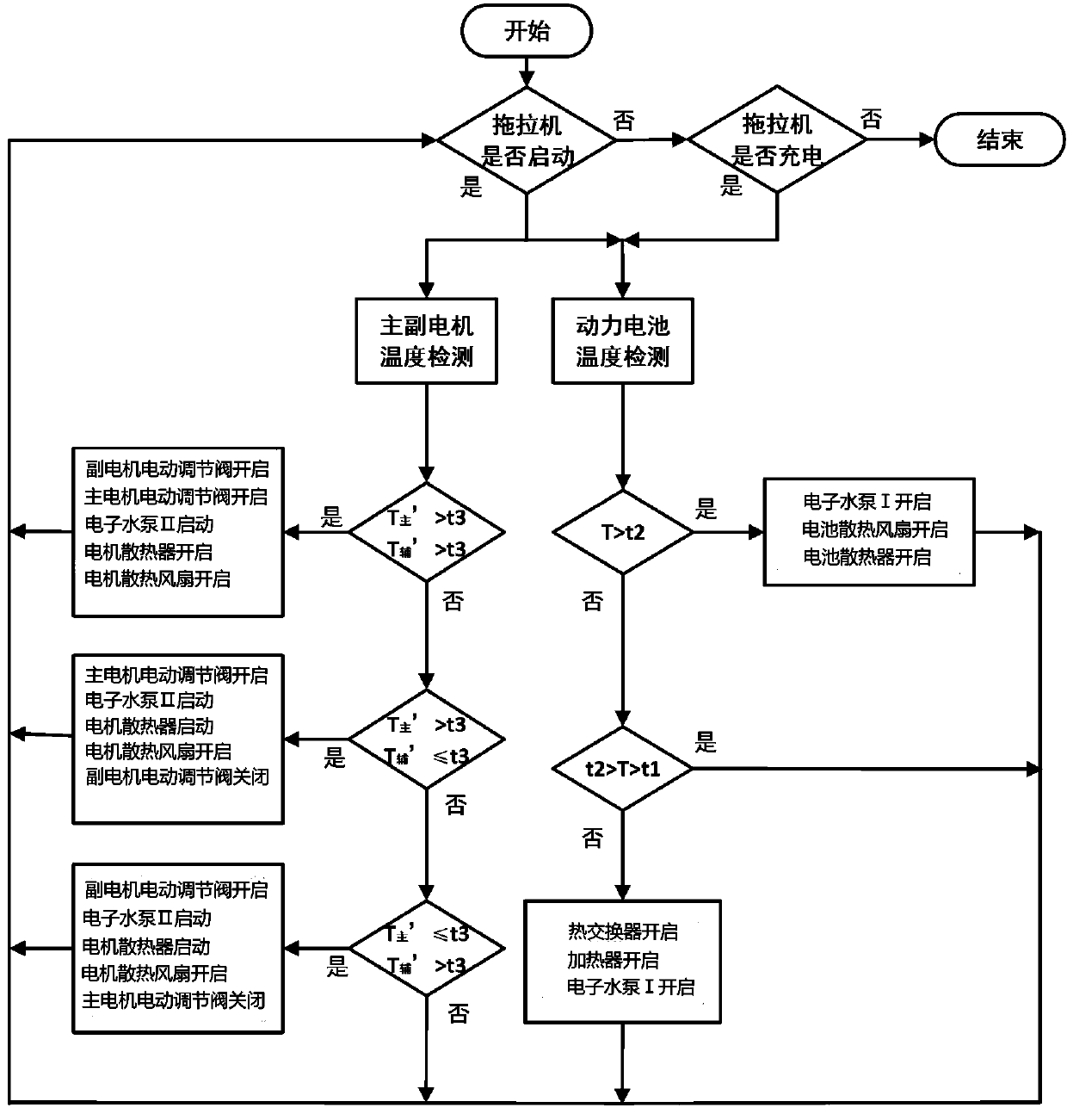

[0025] figure 1 It is a structural schematic diagram of the electric tractor complete machine thermal management system of the present invention. The electric tractor complete machine thermal management system provided by the present invention includes two systems, namely, the power battery thermal management system and the dual-motor thermal management system. The thermal management system of the power battery is connected with the thermal management system of the electric motor through a heat exchanger 15 to realize heat exchange.

[0026] Among them, the power battery thermal management system adopts a liquid cooling-phase change material comprehensive cooling method, and its system includes a battery radiator 19, a battery cooling fan 18, an expansion tank I20, an electronic wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com