Plant for preparing recycled construction materials from construction waste

A technology for recycling building materials and construction waste, which is applied in the field of equipment for preparing recycled building materials from construction waste, and can solve the problems of high work intensity for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

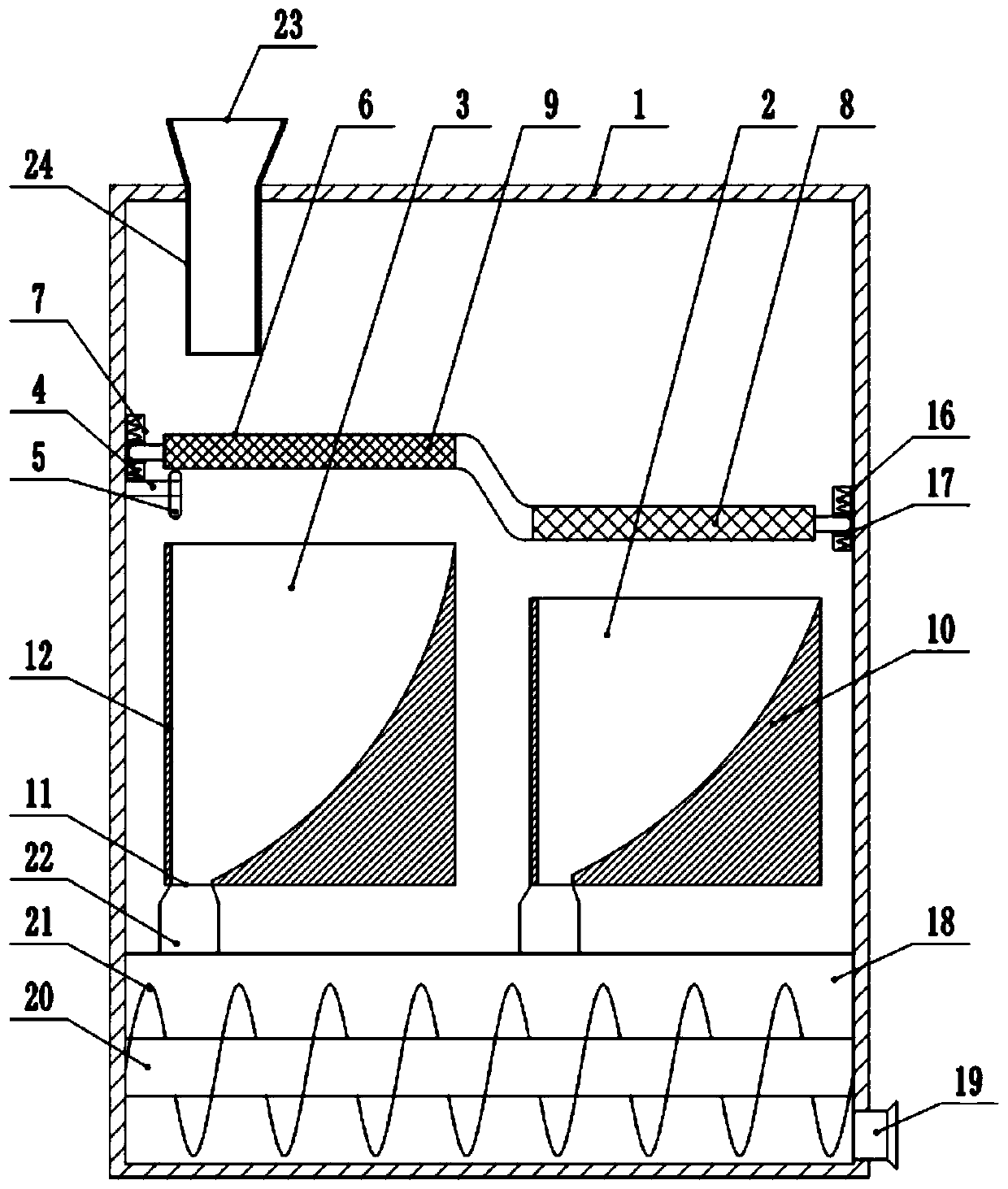

[0030] Embodiment 1 is basically as attached figure 1 As shown: a device for preparing recycled building materials from construction waste, including a shell 1, a feed hopper 23 is welded on the upper part of the shell 1, and a vertical feed channel 24 is welded on the top wall of the shell 1, and The feed channel 24 is located inside the housing 1 . The casing 1 is provided with a screening mechanism capable of simultaneously screening aggregates of different particle sizes, and an adjustable proportioning mechanism is provided below the screening mechanism, and the adjustable proportioning mechanism is connected to a mixing box 18 .

[0031] The screening mechanism is used to screen the crushed construction waste, and screen the crushed construction waste into fine aggregate and coarse aggregate. The screening mechanism includes a sieve plate 6, the left end of the sieve plate 6 is set as a fine screen 9, the right end of the sieve plate 6 is set as a coarse screen 8, the t...

Embodiment 2

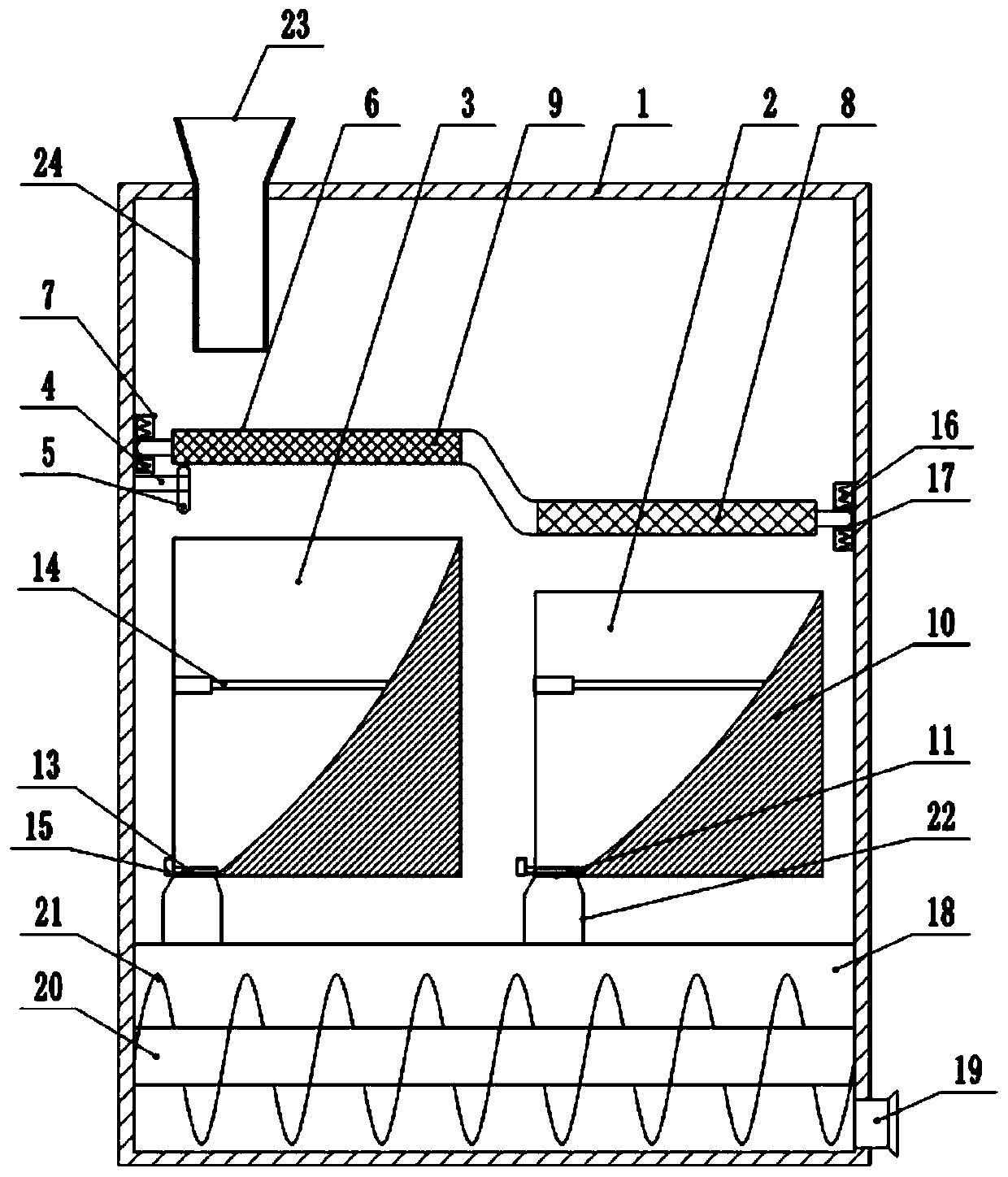

[0041] combine figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the adjustment assembly in this embodiment includes a first telescopic plate 13 fixed on the bottom of the coarse aggregate box 2 / fine aggregate box 3, and the first telescopic plate 13 When stretched, the outlet 11 can be blocked; the upper part of the coarse aggregate box 2 / fine aggregate box 3 is fixedly connected with a second telescopic plate 14, and when the second telescopic plate 14 is stretched, the discharge path of the aggregate can be staged. . The outer wall of the coarse aggregate box 2 / fine aggregate box 3 is fixedly connected with a load cell, the left side wall of the coarse aggregate box 2 / fine aggregate box 3 is provided with a strip hole, and one end of the first telescopic plate 13 is passed through The strip-shaped hole is fixedly connected with the load cell, and the load cell is connected with a controller 15 for controlling the expansion and contraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com