A cooling cycle system

A circulatory system and cooling technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., to achieve high safety, simple and compact structure, and efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

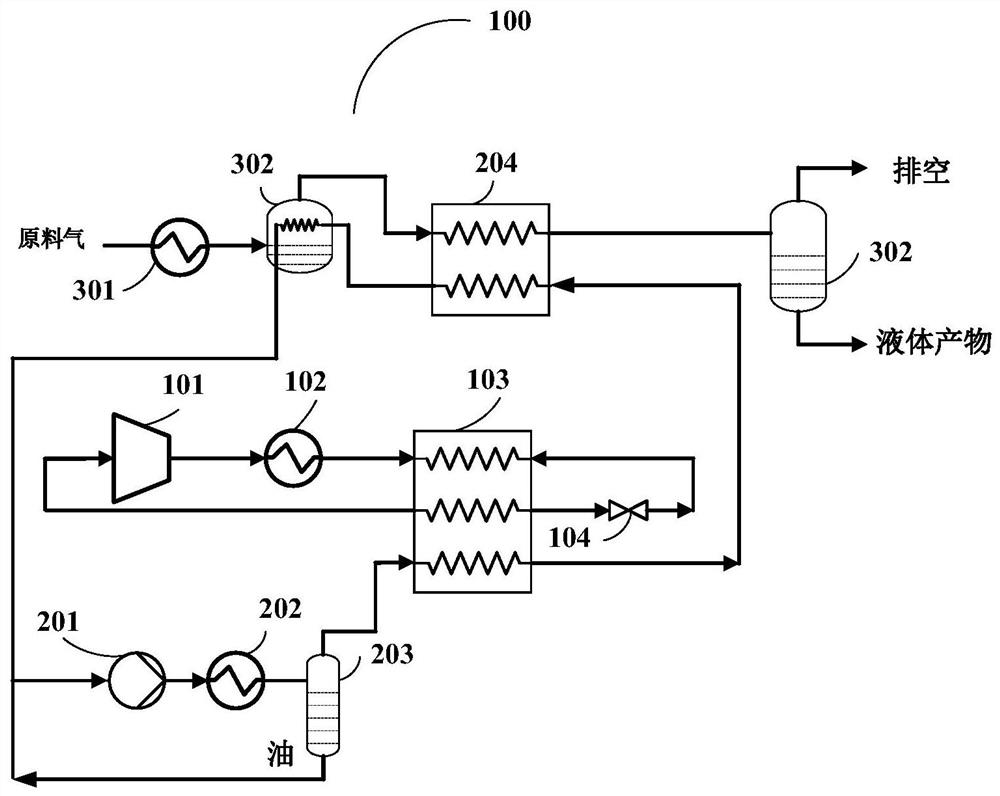

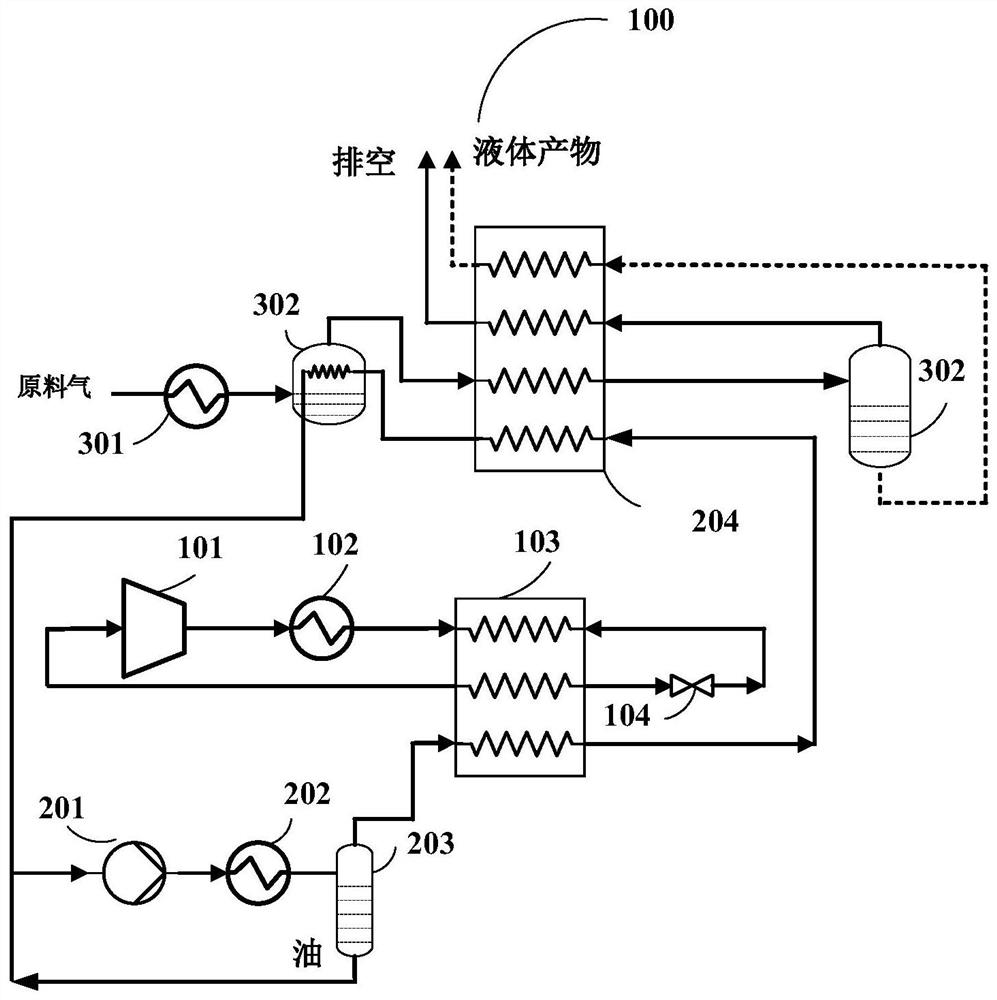

[0026] see figure 1 , is a schematic structural diagram of a load-cooling cycle system provided by Embodiment 1 of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown, and the details are as follows.

[0027]The load cooling cycle system 100 provided by the present invention includes: a mixed working medium refrigeration cycle circuit and a load cooling cycle circuit; the mixed working medium refrigeration circuit includes a mixed working medium compressor (101), a mixed working medium condenser (102), regenerative heat exchanger (103), mixed working medium throttle valve (104); the brine-cooled circulation loop includes a brine-driven pump (201), a brine condenser (202), a precision oil separation system (203 ), regenerative heat exchanger (103), distributed heat exchanger (204) and feed gas precooling separator (302);

[0028] The high-pressure refrigerant outlet of the mixed working medium c...

Embodiment 2

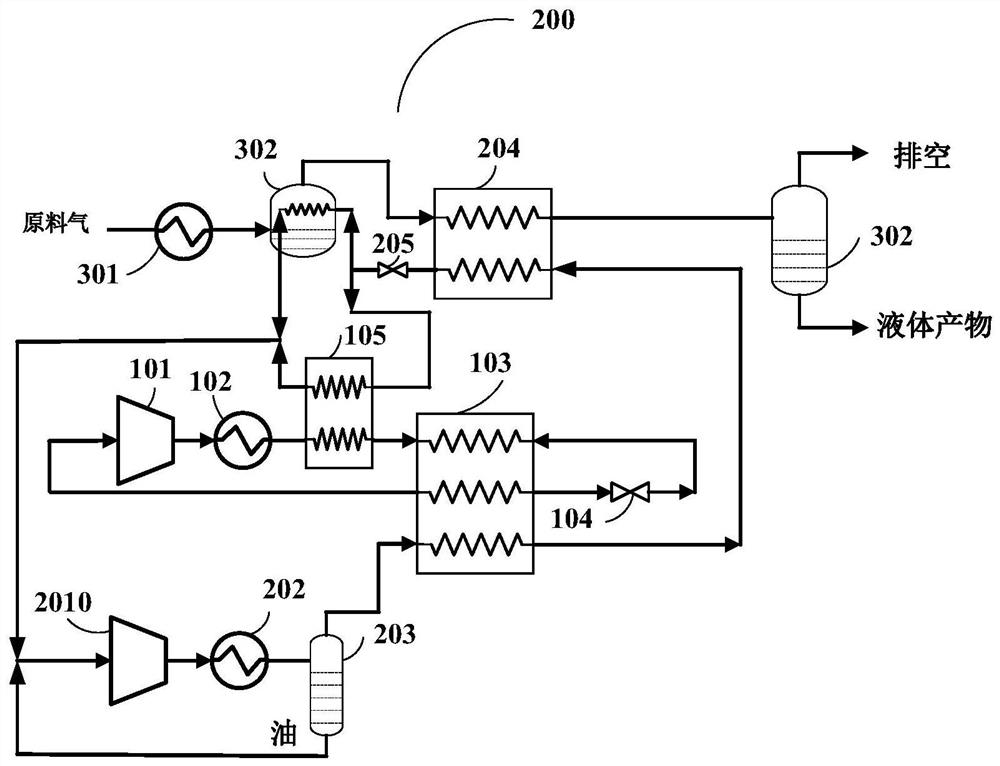

[0036] see image 3 , is a schematic structural diagram of a load-cooling cycle system provided by Embodiment 2 of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown, and the details are as follows.

[0037] A cooling cycle system 200 provided by the present invention includes: a mixed working medium refrigeration cycle and a cooling cycle; the mixed working medium refrigeration circuit includes a mixed working medium compressor (101), a mixed working medium condenser (102 ), a recuperative heat exchanger (103), a mixed working medium throttle valve (104) and a mixed working medium precooling heat exchanger (105); Refrigerant condenser (202), precision oil separation system (203), heat recovery heat exchanger (103), distributed heat exchanger (204), brine throttle valve (205) and feed gas precooling separator (302);

[0038] The high-pressure refrigerant outlet of the mixed working medium com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com