A casing air tightness detection system

A detection system, a technology of casing gas, which is used in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, and detection of the appearance of fluid at the leak point. The problem of low detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

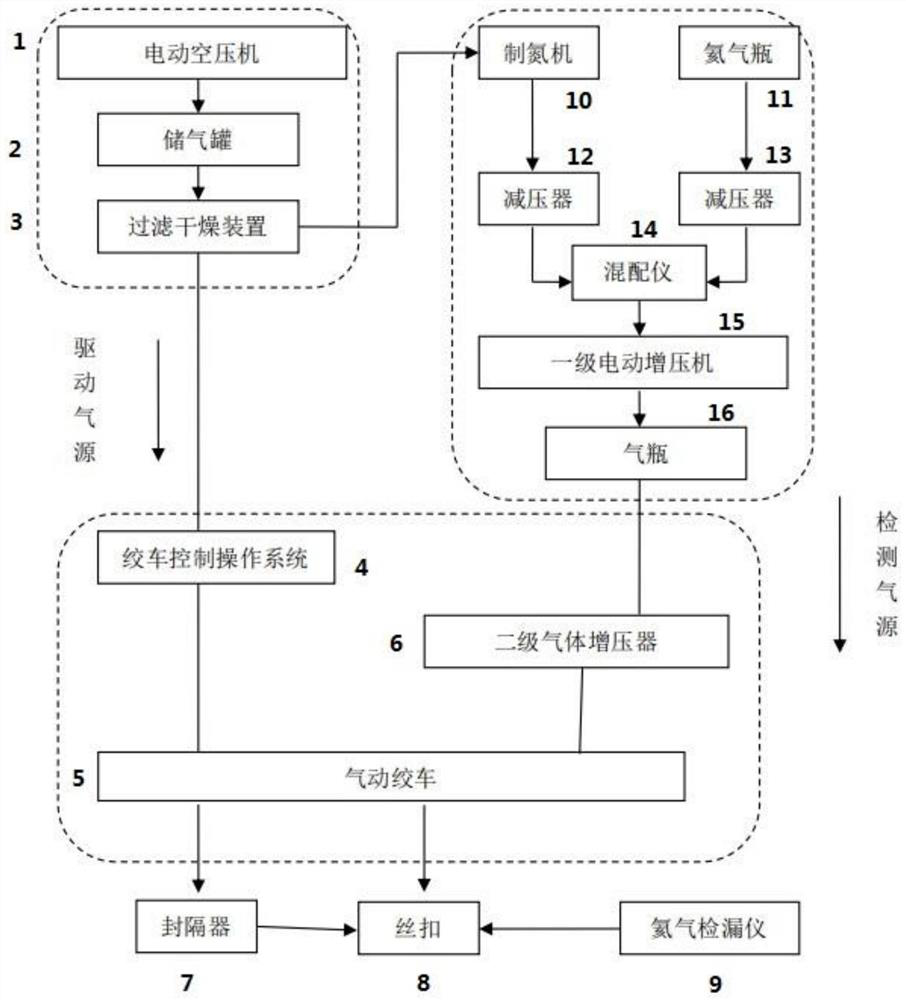

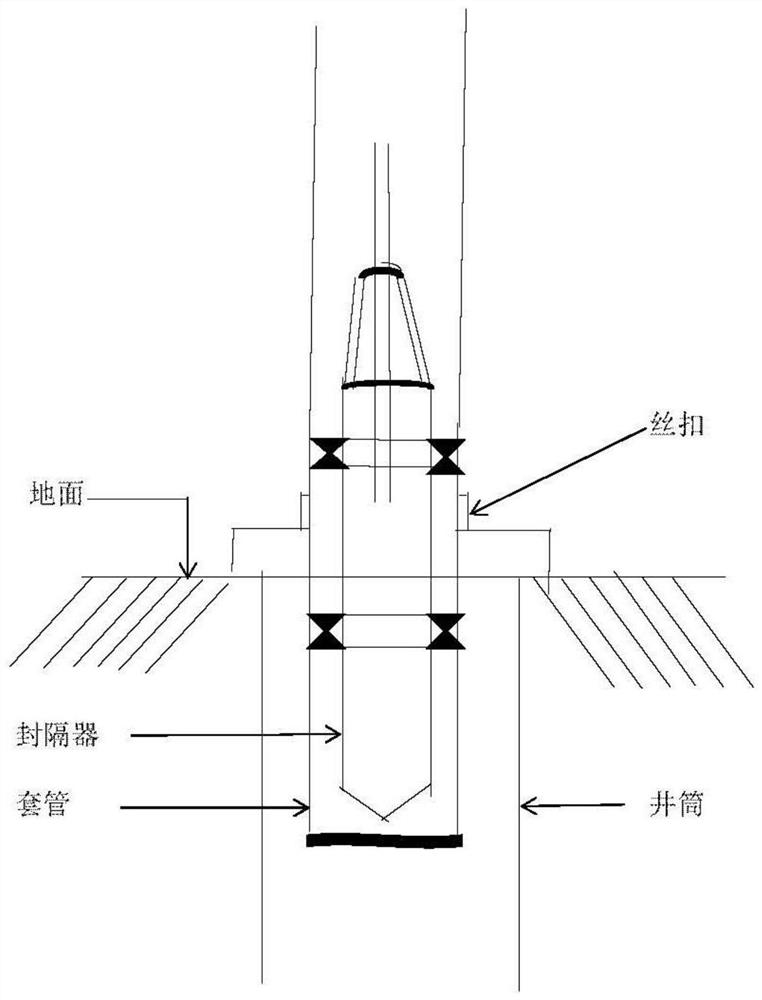

[0015] Such as figure 1 As shown, the casing air tightness detection system includes a high-pressure pressure unit, a mixing unit and a pneumatic winch unit, wherein,

[0016] The high pressure unit comprises an electric air compressor 1, an air storage tank 2 and a dry filter 3,

[0017] The mixing unit comprises a nitrogen generator 10 and a helium cylinder 11, a first pressure reducer 12 is provided downstream of the nitrogen generator 10, a second pressure reducer 13 is provided downstream of the helium cylinder 11, and the first pressure reducer 13 is provided downstream of the helium cylinder 11. The outlets of a pressure reducer 12 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com