A capacitor production inkjet equipment

A technology for capacitors and inkjet coding, which is applied in capacitors, capacitor manufacturing, circuits, etc. It can solve problems such as polluting the working environment, affecting ink output, and time-consuming and laborious cleaning of nozzles, and achieves the effects of improving dissolution efficiency and preventing liquid accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

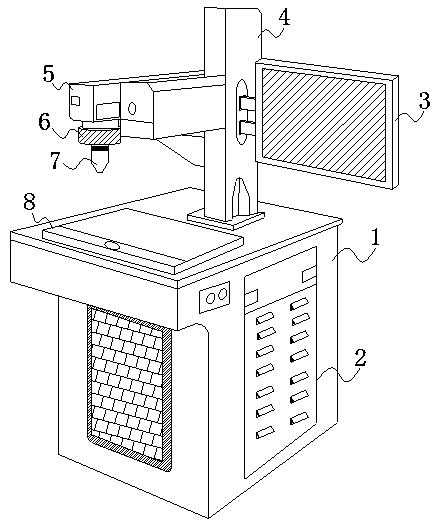

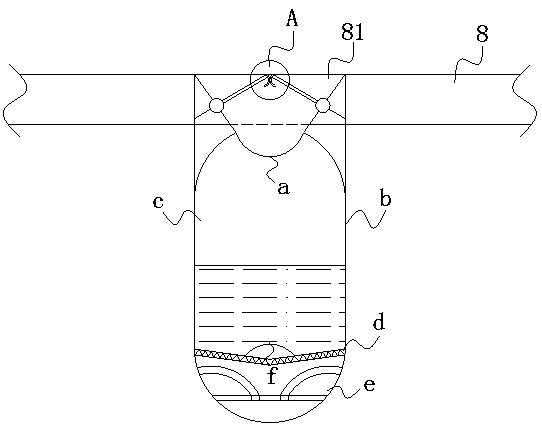

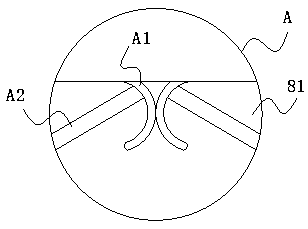

[0027] Such as Figure 1-Figure 5 As shown, the present invention provides a kind of inkjet equipment for producing capacitors. Its structure includes a main box 1, a heat dissipation cover 2, a computer board 3, a lifting column 4, a machine head 5, a distance adjustment plate 6, a nozzle 7, and a workbench 8. The circuit system inside the lifting column 4, the computer board 3, the machine head 5, and the distance adjusting disc 6 are all located in the main box 1, and the heat dissipation cover 2 is installed on the main box 1, and the main box 1 is opposite to the nozzle 7. A workbench 8 is fixed on the position, the computer board 3 is controlled by the machine head 5 and the nozzle 7, the lifting column 4 is movable to cooperate with the machine head 5, and a nozzle is arranged at the bottom of the end of the machine head 5 away from the lifting column 4 7. The nozzle 7 cooperates with the distance adjustment disc 6, and the position where the workbench 8 is facing the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com