Method for removing sticky components in neotame

A neotame and viscous technology, which is applied in the field of removing viscous components in neotame, can solve the problems of restricting the industrialization development of neotame, affecting product storage and usability, and prone to sticky lumps, so as to reduce the content of viscous substances, Easy to achieve, extended shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Dissolve 500 grams of neotame in a system consisting of 2000 grams of purified water and 250 grams of methanol, and heat up to 50°C to dissolve it.

[0028] (2) Add sodium hydroxide, stir at 70°C for 1.5h, and control the pH of the solution to 10.

[0029] (3) Add hydrochloric acid to adjust the pH of the solution to 7.0 for neutralization.

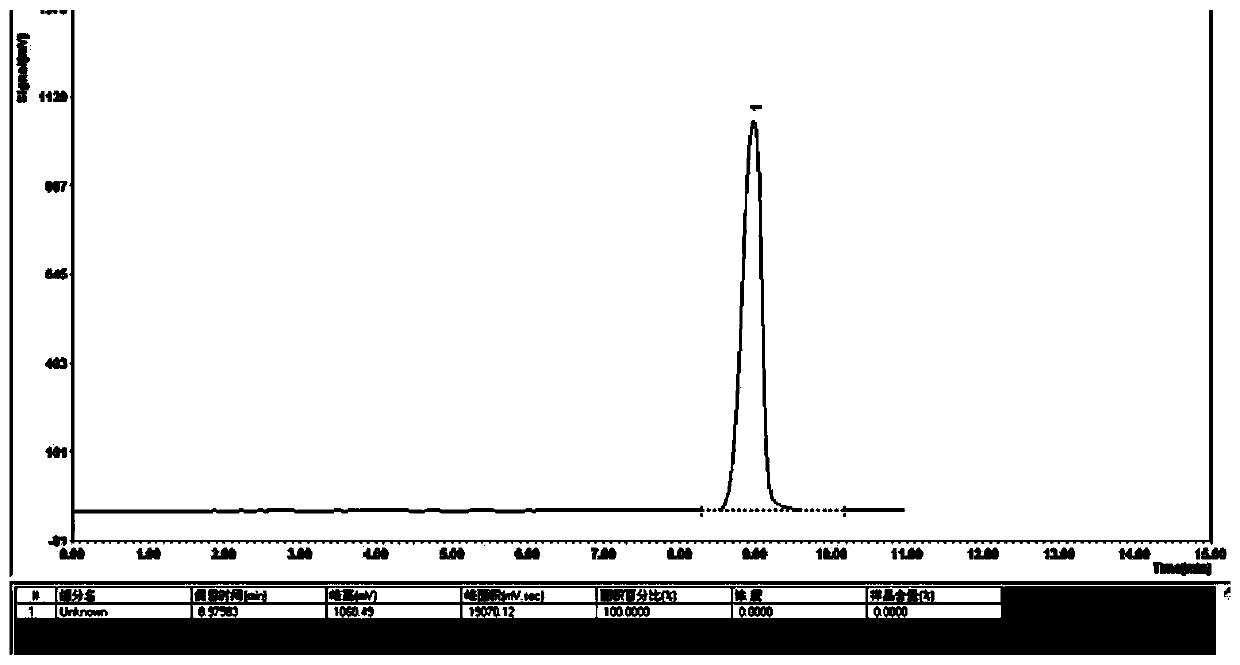

[0030] (4) Static crystallization, the crystallization temperature is 40 ° C, the crystallization time is 12 hours, centrifuged, the centrifuge speed is 1200 rpm, and GB 29944-2013 is used for detection. The high performance liquid chromatogram is attached figure 1 As shown, the obtained neotame viscous substance content is 0, which is lower than the traditional content of 0.1%. After 2 months of observation, there is no obvious agglomeration, and the sensory index is good.

Embodiment 2

[0032] (1) Dissolve 500 grams of neotame in a system consisting of 2000 grams of purified water and 250 grams of methanol, and heat up to 80°C to dissolve it.

[0033] (2) Add sodium bicarbonate, stir at 95° C. for 1.0 h, and control the pH of the solution to 9.5.

[0034] (3) adding hydrochloric acid to adjust the pH of the solution to be 8 for neutralization.

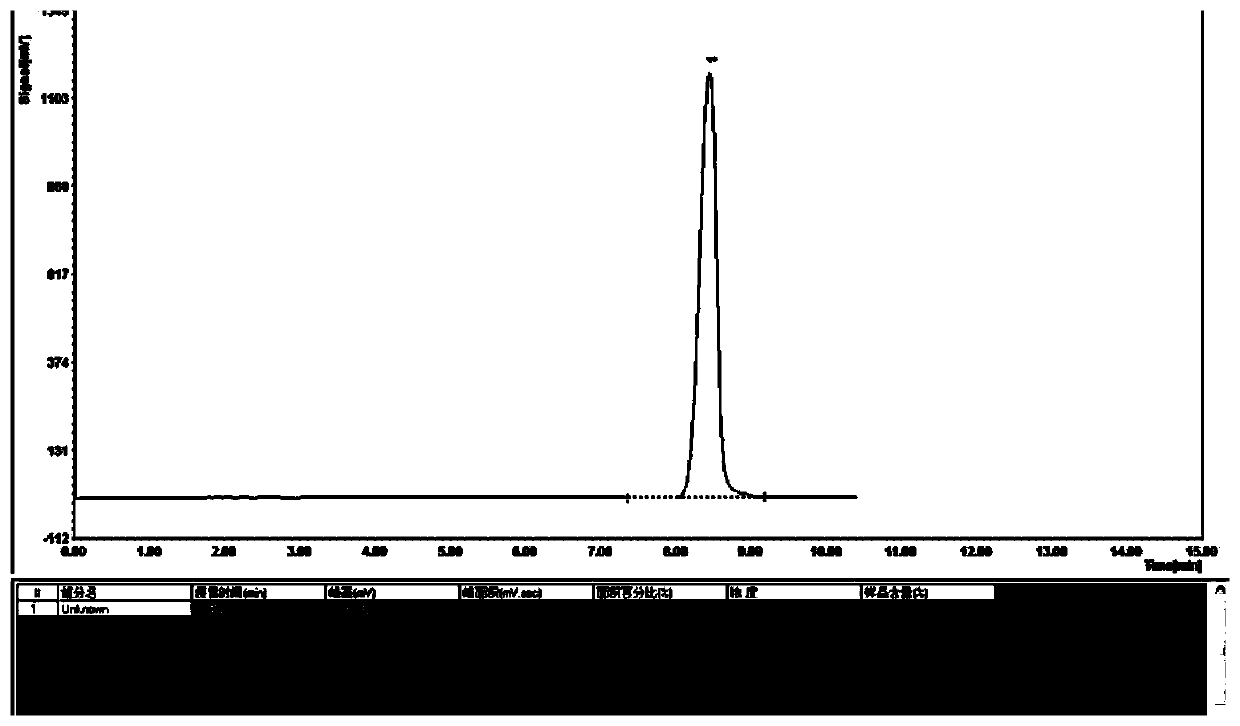

[0035] (4) Static crystallization, the crystallization temperature is 20 ° C, the crystallization time is 24 hours, centrifuged, the centrifuge speed is 1100 rpm, and GB 29944-2013 is used for detection. The high performance liquid chromatogram is as attached figure 2 As shown, the obtained neotame viscous substance content is 0, which is lower than the traditional content of 0.1%. After 2 months of observation, there is no obvious agglomeration, and the sensory index is good.

Embodiment 3

[0037] (1) Dissolve 500 grams of neotame in a system consisting of 2000 grams of purified water and 250 grams of methanol, and dissolve it at 20°C.

[0038] (2) Add sodium carbonate, stir at 35°C for 3h, and control the pH of the solution to 9.

[0039] (3) Add hydrochloric acid to adjust the pH of the solution to 7.0 for neutralization.

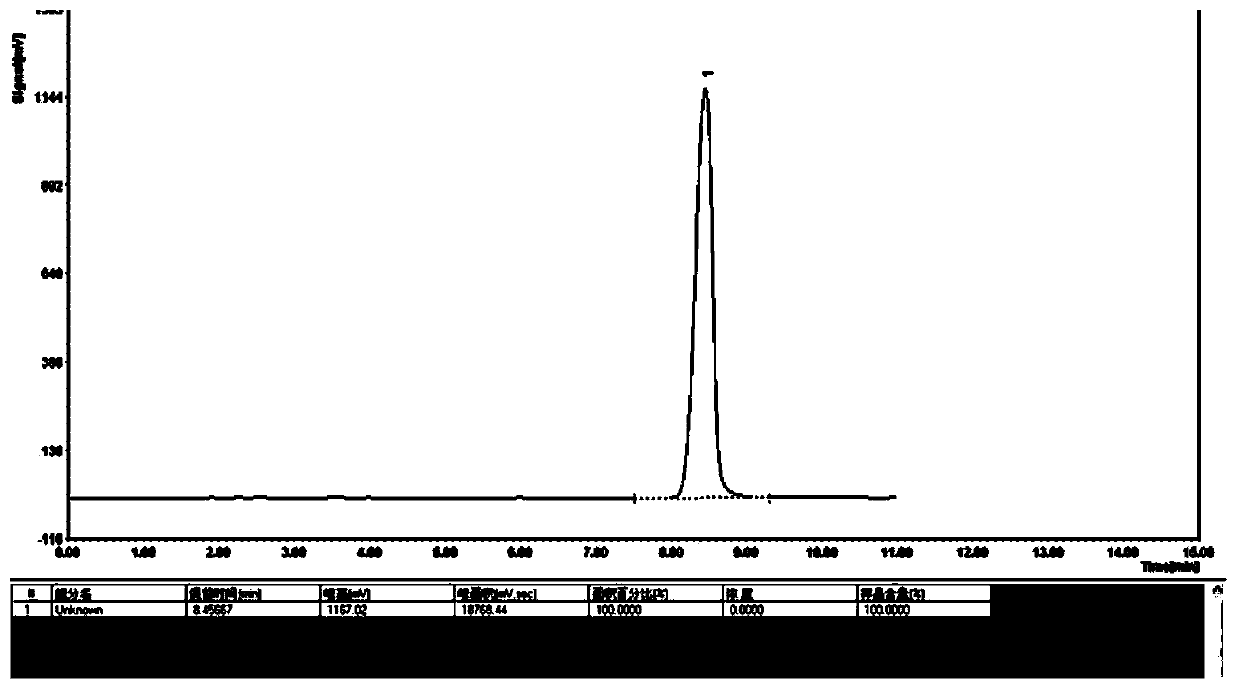

[0040] (4) Static crystallization, the crystallization temperature is 0 ° C, the crystallization time is 36 hours, centrifuged, the centrifuge speed is 1200 rpm, and GB 29944-2013 is used for detection. The high performance liquid chromatogram is attached image 3 As shown, the obtained neotame viscous substance content is 0, which is lower than the traditional content of 0.1%. After 2 months of observation, there is no obvious agglomeration, and the sensory index is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com