Novel smoke gas turbine power generating device

A technology of turbine power generation and flue gas, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., to achieve the effect of miniaturization and integration, avoiding failure, and avoiding mechanical rotation wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

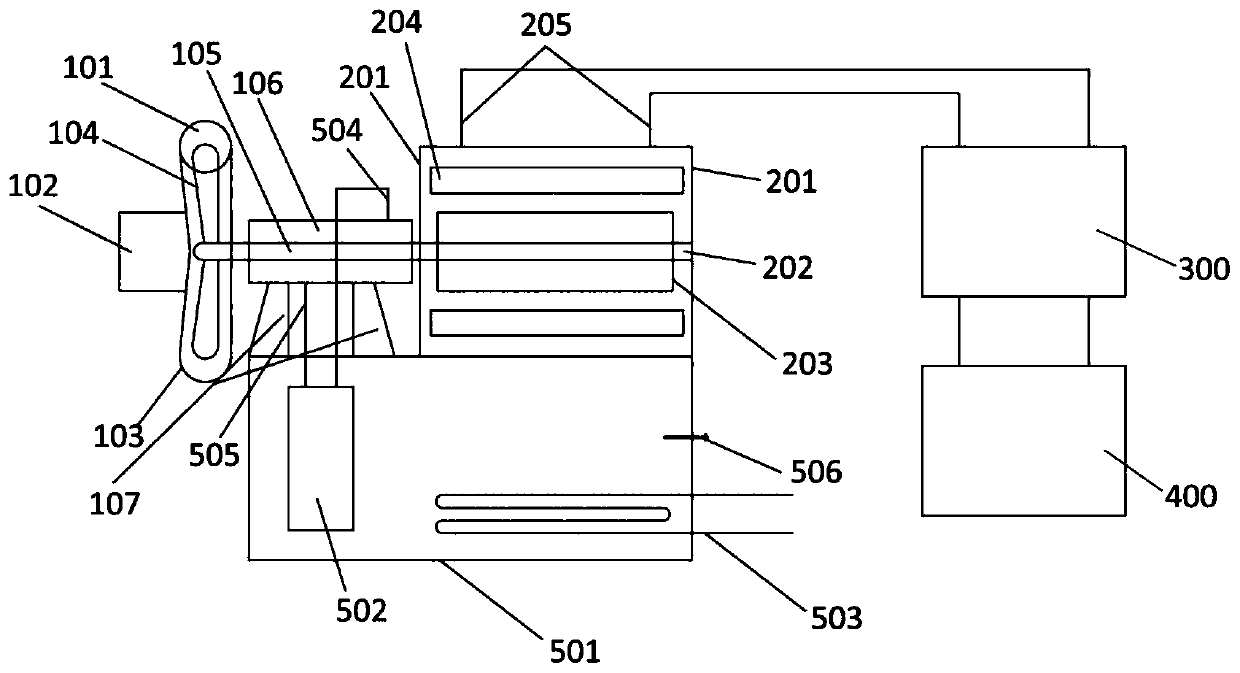

[0025] The new flue gas turbine power generation device described in this embodiment, see figure 1 , including a flue gas turbine system 100, a generator system 200, a voltage transformation system 300, and a voltage stabilizing system 400; the flue gas turbine system 100 is provided with a high-temperature pressurized wet flue gas inlet pipe 101 and a flue gas outlet pipe 102, the The flue gas turbine system 100 is connected to the generator system 200 , the generator system 200 is connected to the voltage transformation system 300 , and the voltage transformation system 300 is connected to the voltage stabilization system 400 .

[0026] Further, the flue gas turbine system 100 includes a volute 103, a turbine 104, a turbine shaft 105 and a turbine shaft box 106, the volute 103 is radially connected with a high-temperature pressurized wet flue gas inlet pipe 101, the volute A flue gas outlet pipe 102 is connected axially at the center of 103, the turbine 104 is connected and ...

Embodiment 2

[0035] The turbine shaft 105 in Embodiment 1 can be replaced by a gear shaft, and the gear shaft and the generator shaft 202 are coaxially linked.

Embodiment 3

[0037]The U-tube lubricating oil cooler described in Embodiment 1 can be replaced by a coil lubricating oil cooler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com