Method for manufacturing metal nanowire, semiconductor device, and method for manufacturing same

A technology of metal nanowires and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc. Equal problem, to achieve the effect of guaranteed performance, good side wall morphology, high thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

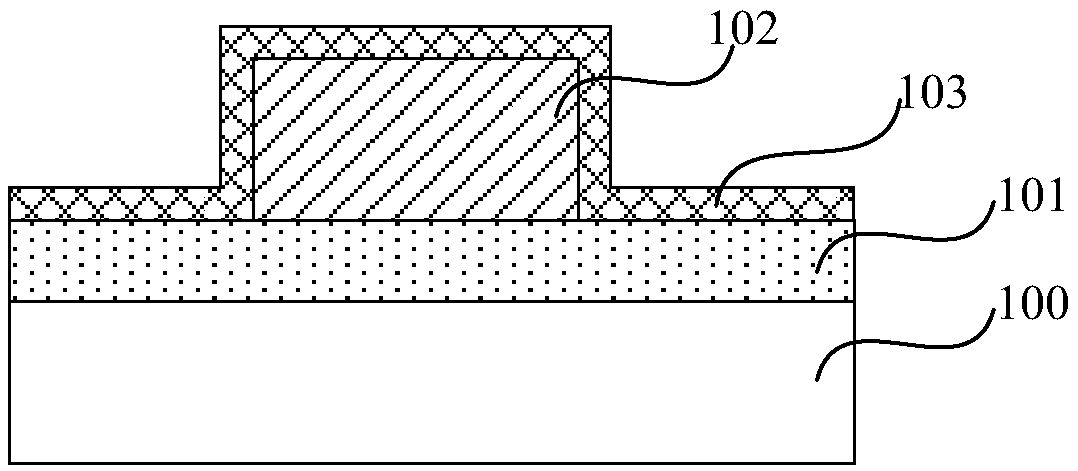

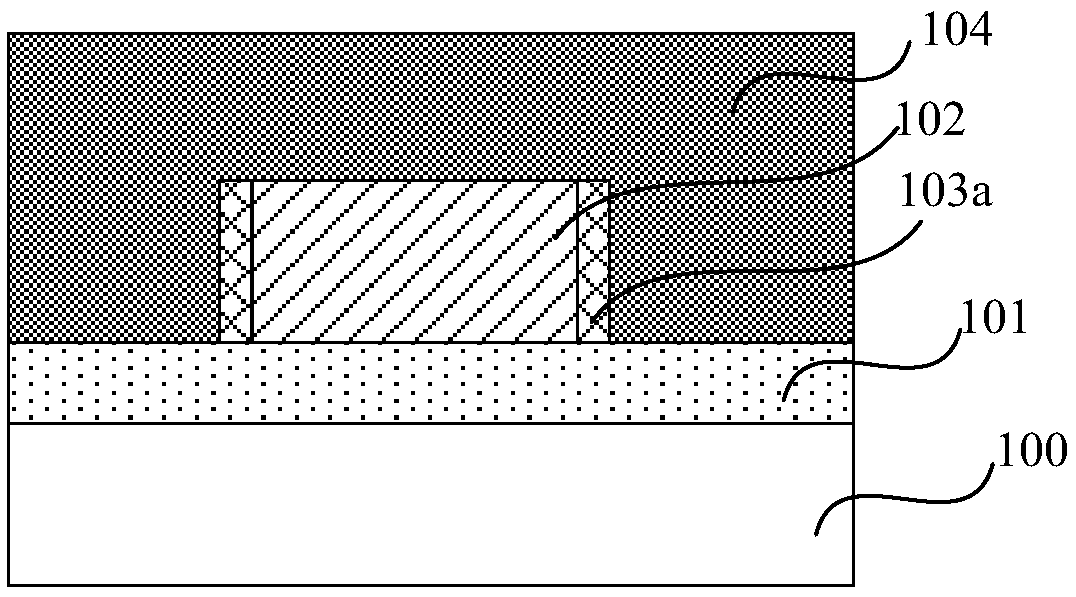

[0051] Please refer to 1A to 1E , a known method of manufacturing a semiconductor device with metal nanowires, comprising the steps of:

[0052] First, please refer to Figure 1A On a semiconductor substrate 100, the bottom anti-reflection layer (for example, SiCN) 101 and the core layer are sequentially covered, and the core layer is patterned through processes such as photoresist coating, exposure, and development to form a patterned core layer. nuclear layer 102;

[0053] Then, please continue to refer to Figure 1A , using a deposition process of materials such as Ru to cover the surface of the patterned core layer 102 and the etching stop layer 101 with a metal layer 103, and the deposition thickness of the metal layer 103 in each region is basically the same;

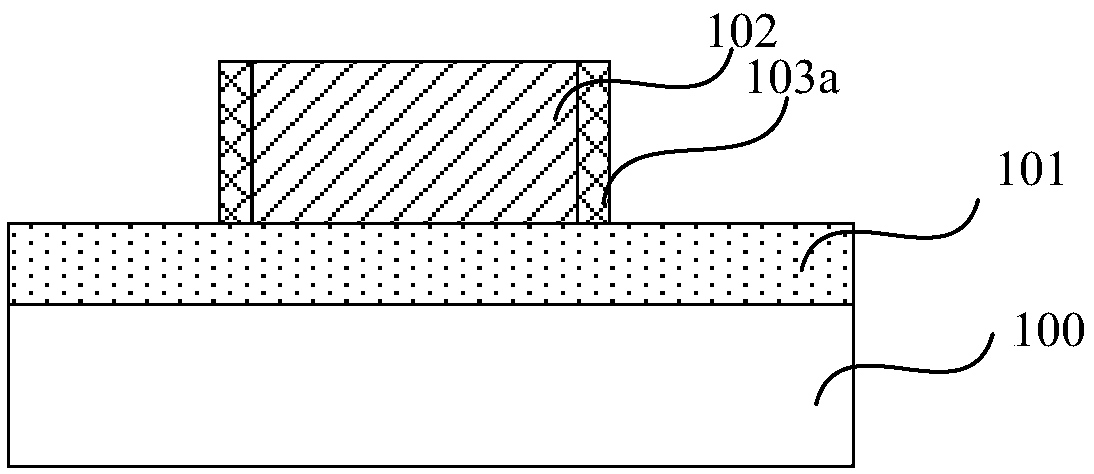

[0054] Next, please refer to Figure 1B , using an anisotropic metal etching process to etch the metal layer until the top surface of the patterned core layer 102 and the top surface of the etch stop layer 101...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com