Display panel and preparation method thereof

A technology for display panels and preparation steps, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve problems such as poor flexibility, affecting the optical performance of display panels, and poor water and oxygen resistance performance, so as to reduce fracture risk, improve the ability to isolate water and oxygen, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

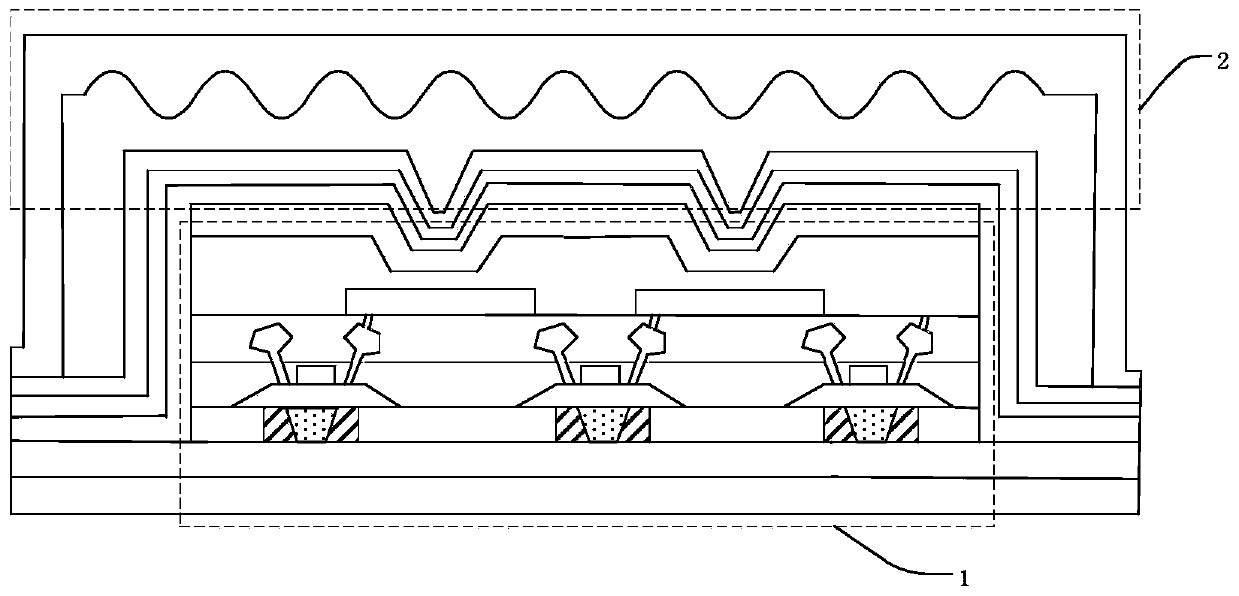

[0034] Such as figure 1 As shown, this embodiment provides a display panel, including a base substrate 1 and a thin film encapsulation layer 2 , and the thin film encapsulation layer 2 is the upper surface of the base substrate 1 .

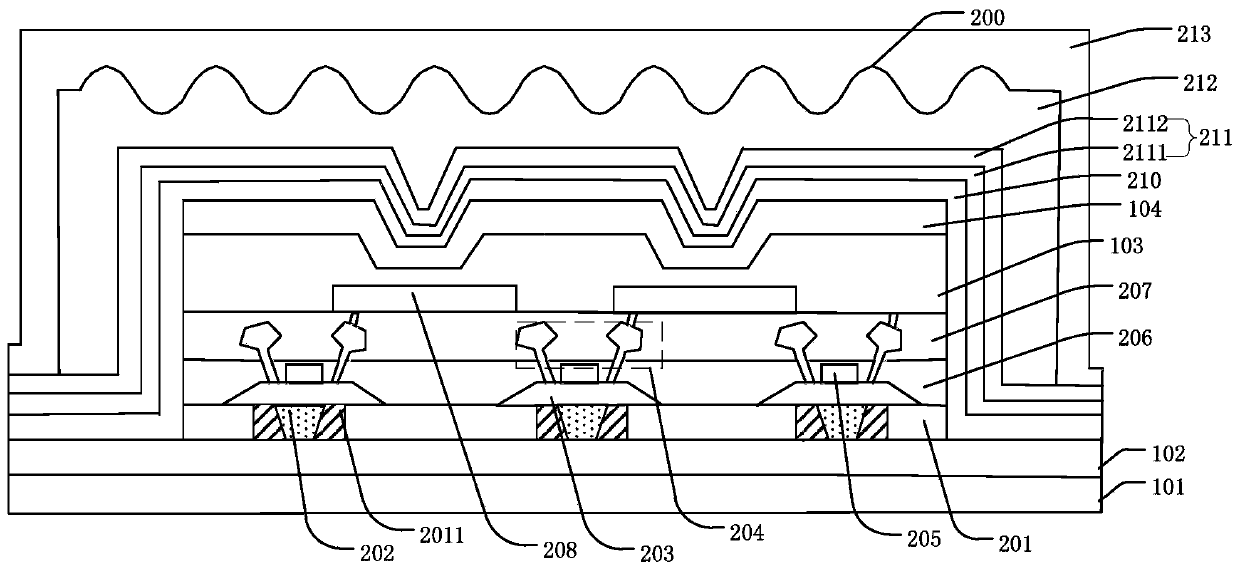

[0035] Such as figure 2 As shown, the base substrate 1 includes a glass substrate 101 , a PI substrate 102 , a thin film transistor, a pixel definition layer 103 and a light emitting layer 104 .

[0036] The glass substrate 101 is a glass substrate in the prior art. The PI substrate 102 is a flexible substrate, and its material is mainly polyimide (PI). The PI material can effectively improve light transmittance. Each thin film transistor includes an active layer 201 (P-type doped), a polysilicon layer 202 , a dielectric layer 203 , source and drain electrodes 204 , a gate electrode 205 , an insulating layer 206 , a planar layer 207 and an anode 208 . Specifically, a doped region 2011 is provided in the active layer 201, and the doped region 2...

Embodiment 2

[0062] Such as Figure 7 As shown, this embodiment provides a display panel, which includes most of the technical features of the display panel described in Embodiment 1, and its distinguishing feature is that in Embodiment 2, the laminated film layer 211 is provided on the second inorganic layer 210 and the organic between the first inorganic layer 210 and the organic layer 212 instead of between the first inorganic layer 210 and the organic layer 212 .

[0063] Such as Figure 7 As shown, the thin film encapsulation layer in the display panel includes a first inorganic layer 210 , an organic layer 212 , a stacked film layer 211 and a second inorganic layer 213 from bottom to top.

[0064] Each stacked film layer 211 includes a dense film layer 2111 and an interlayer 2112 .

[0065] In this embodiment, the transition layer 2112 is disposed on the upper surface of the organic layer 212 , and the dense film layer 2111 is disposed on the upper surface of the transition layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com