Touch keyboard gold stamping machining technique based on glass material

A technology of keyboard bronzing and processing technology, which is applied in the fields of crafts and decorative arts for producing decorative surface effects, and can solve problems such as defects in bronzing techniques, and achieve the effects of strong plasticity, reduced protection, and prevention of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

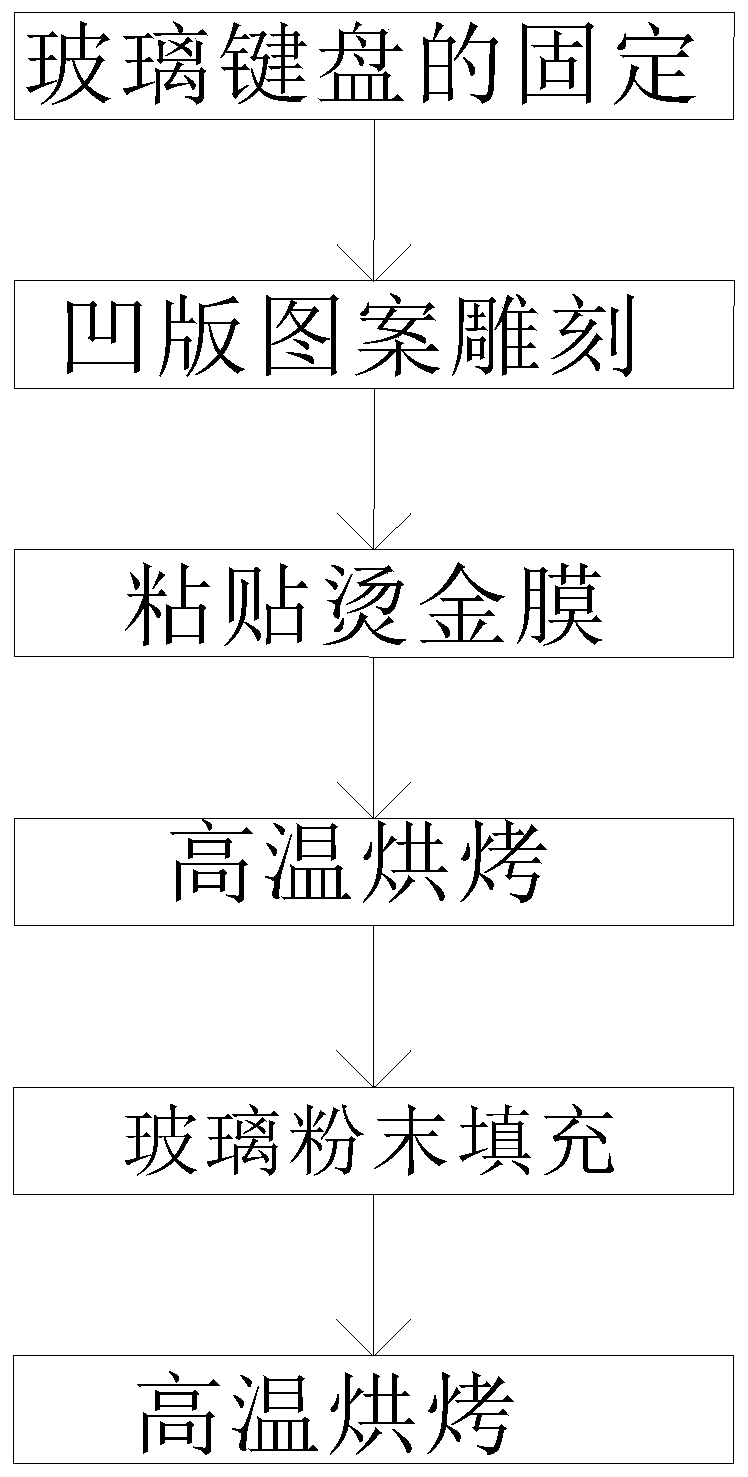

[0029] Such as figure 1 As shown: the embodiment of the present invention provides a touch keyboard bronzing process based on glass material, including the following steps:

[0030] 1) The operating surface of the glass keyboard faces up and is fixed in the mold.

[0031] 2) Carry out gravure pattern engraving on the operating surface of the glass touch keyboard with a laser engraving machine, the depth of the pattern is 1.7mm, then wash it with clean water, dry it at 40°C, wipe and clean it with absolute alcohol, and let it dry naturally Dry, clear impurities in the gravure pattern.

[0032] 3) After the bronzing film is dried on the surface, a layer of adhesive is coated on the surface of the bronzing film, and then the bronzing film is covered in the engraved pattern on the keyboard operation panel, and the edge is pressed to make the bronzing film completely Covered in the engraved pattern, then let it stand for 1.5 hours; wherein the adhesive is composed of polyvinyl ac...

Embodiment 2

[0039] An embodiment of the present invention provides a touch keyboard bronzing process based on glass material, which includes the following steps:

[0040] 1) The operating surface of the glass keyboard faces up and is fixed in the mold.

[0041] 2) Carry out gravure pattern engraving on the operating surface of the glass touch keyboard with a laser engraving machine, the depth of the pattern is 1.6mm, then wash it with clean water, dry it at 44°C, wipe and clean it with absolute alcohol, and let it dry naturally Dry.

[0042] 3) After the bronzing film is dried on the surface, a layer of adhesive is coated on the surface of the bronzing film, and then the bronzing film is covered in the engraved pattern on the keyboard operation panel, and the edge is pressed to make the bronzing film completely Covered in the engraved pattern, then let it stand for 1.2 hours; wherein the adhesive is composed of polyvinyl acetate, hydroxypropyl methylcellulose, stearic acid, tricalcium ph...

Embodiment 3

[0048] An embodiment of the present invention provides a touch keyboard bronzing process based on glass material, which includes the following steps:

[0049] 1) The operating surface of the glass keyboard faces up and is fixed in the mold.

[0050] 2) Carry out gravure pattern engraving on the operating surface of the glass touch keyboard with a laser engraving machine, the depth of the pattern is 2.0mm, then wash it with clean water, dry it at a temperature of 50°C, wipe and clean it with absolute alcohol, and let it dry naturally Dry.

[0051] 3) After the bronzing film is dried on the surface, a layer of adhesive is coated on the surface of the bronzing film, and then the bronzing film is covered in the engraved pattern on the keyboard operation panel, and the edge is pressed to make the bronzing film completely Covered in the engraved pattern, then let it stand for 2 hours; wherein the adhesive is composed of polyvinyl acetate, hydroxypropyl methylcellulose, stearic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com