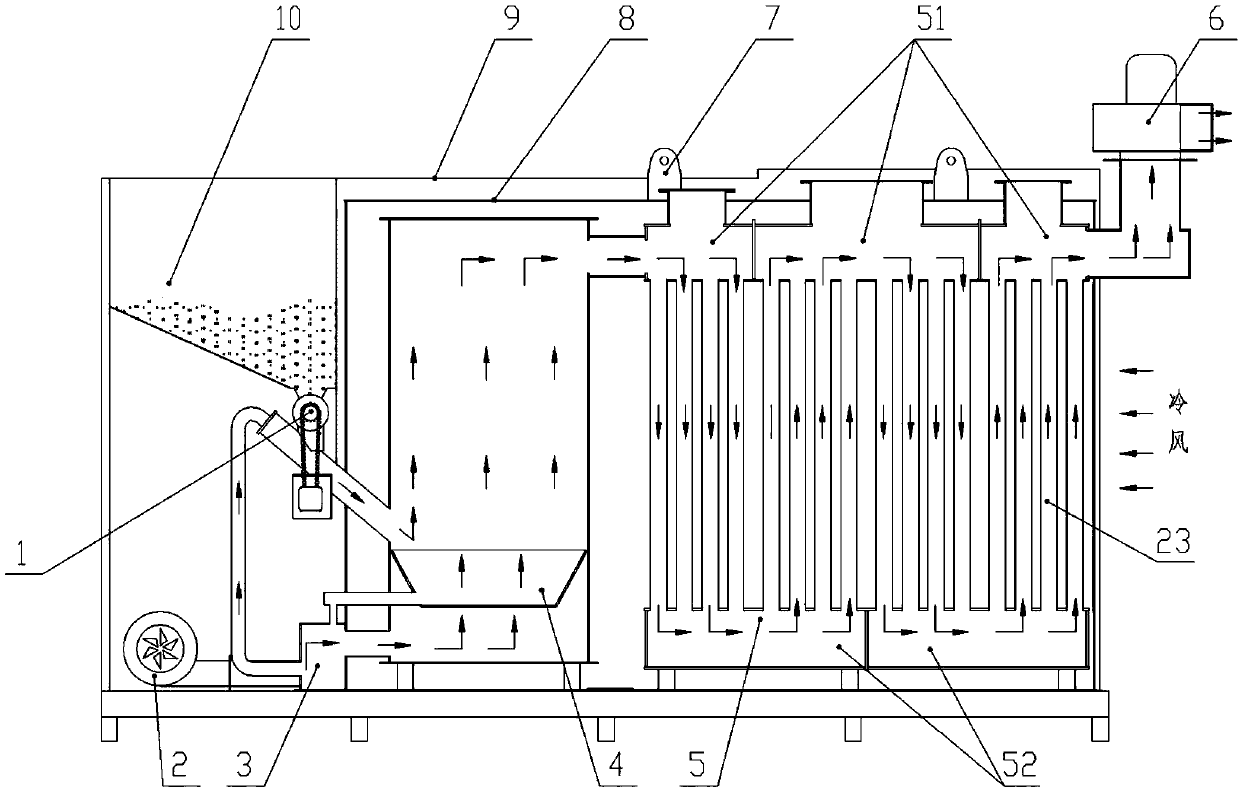

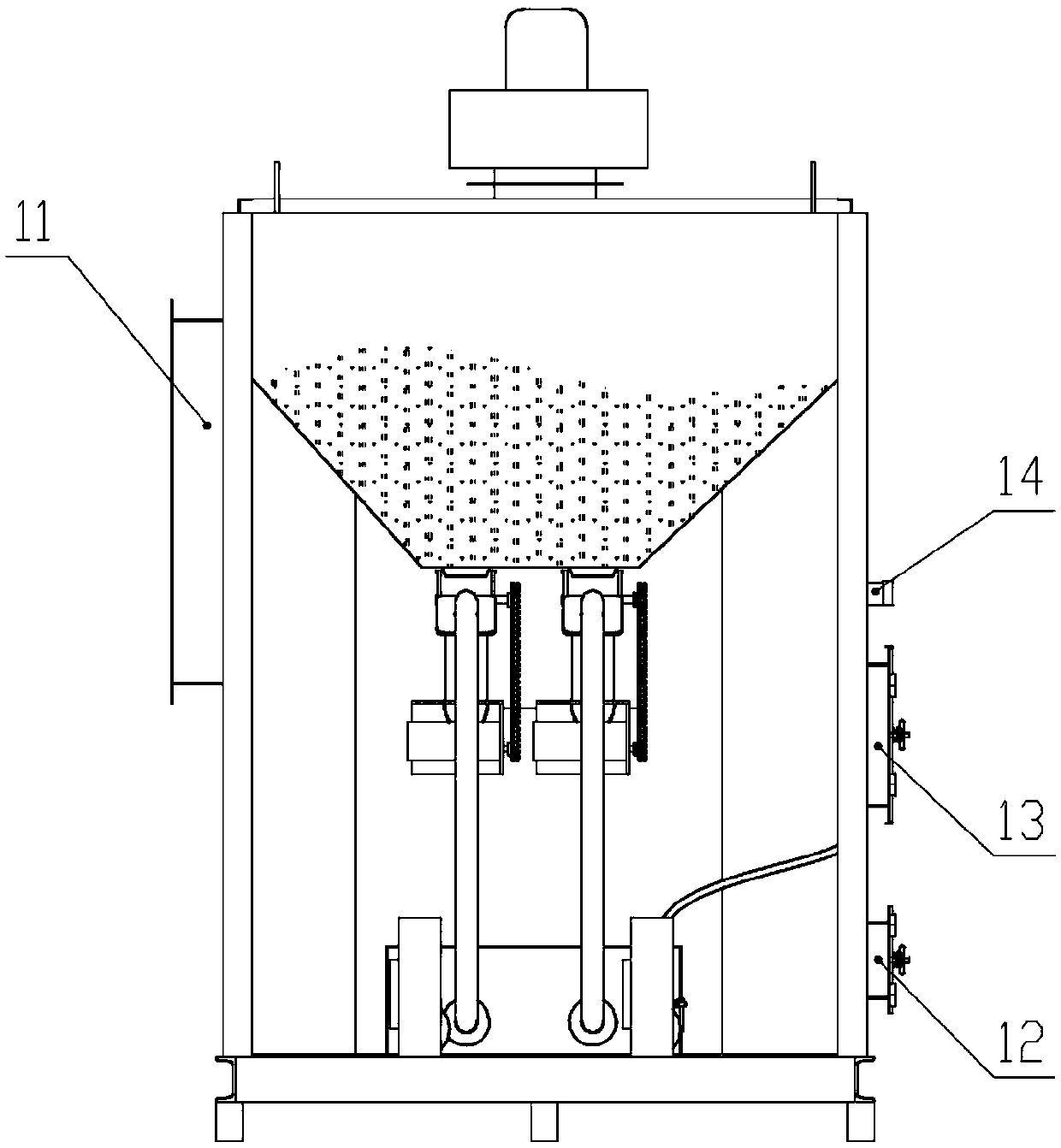

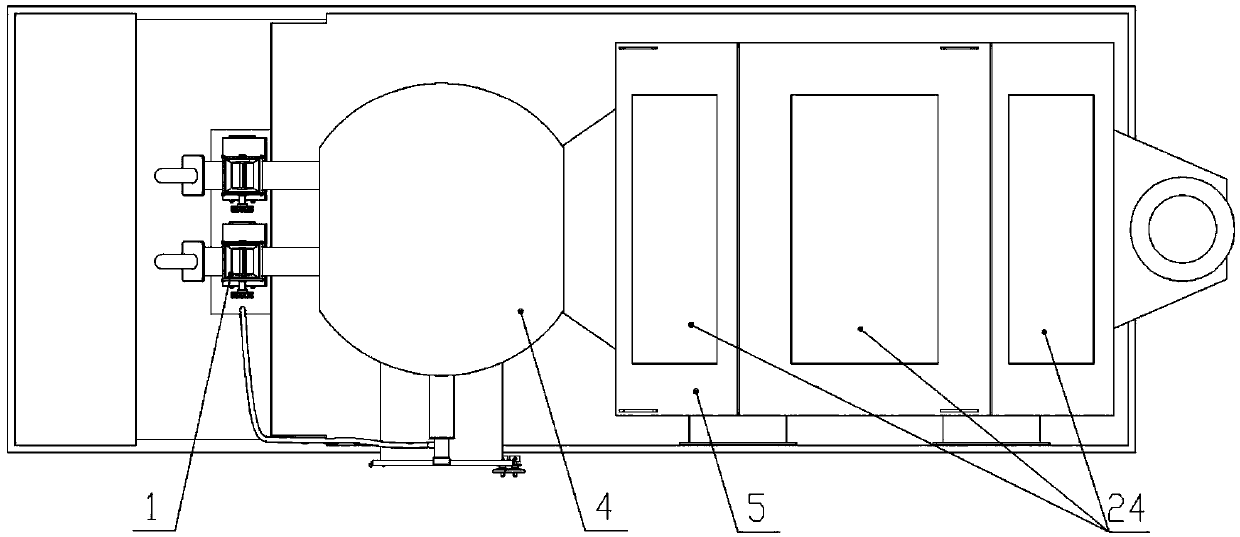

Biomass particle furnace

A biomass particle and furnace technology, applied in air heaters, blast equipment, combustion methods, etc., can solve the problems of large wind resistance, difficult heat extraction, complex structure, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] According to one embodiment, the main cavity 31, the material pipe air supply pipe 18, the ignition pipe channel 32, and the furnace connecting pipe 33 all have uniform cross-sections, and their cross-sectional area ratios are 5-8:1.5-2:1:1.5-3 . This ratio can more effectively realize the efficiency of each duct ventilation.

[0037] When the feeding system 1 includes a plurality of feeding pipes 15 , the air distribution system will have a corresponding number of feeding pipes 18 . In addition, there may be multiple furnace connecting pipes 33, so that the efficiency of air intake to the furnace is higher. There can also be multiple blowers 2, and in the case of multiple blowers 2, the main cavity can be divided into a plurality of independent small compartments, so that each blower can blow air to each small compartment respectively.

[0038] According to one embodiment, the ignition device is a heat-insulating ceramic heating core, and the heating core is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com