Erbium-doped fluoride fiber laser device and laser generation method

A fiber laser and fluoride technology, applied in the field of lasers, can solve the problems of not being used and the efficiency of fiber lasers being reduced, and achieve the effects of stable work, improved energy utilization, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] An erbium-doped fluoride fiber laser, the fiber laser comprising:

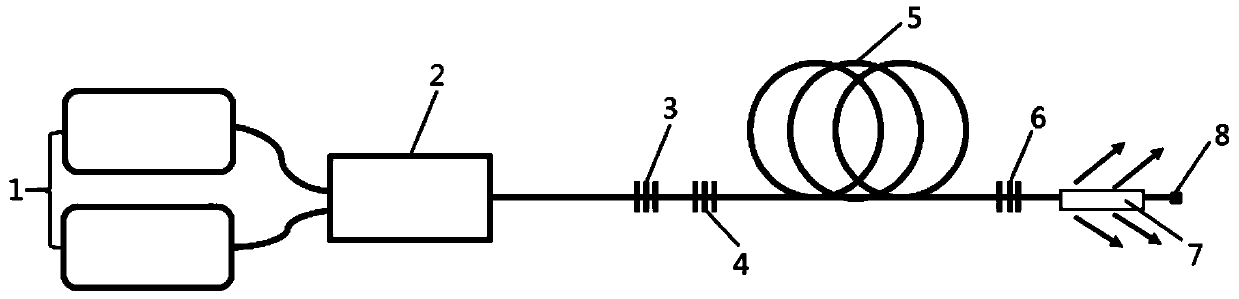

[0043] Such as figure 1 As shown, 976nm pump laser 1, beam combiner 2, first fiber Bragg grating 3, second fiber Bragg grating 4, double-clad erbium-doped fluoride fiber 5, third fiber Bragg grating 6, cladding mode stripper 7. AlF 3 end cap8.

[0044] The reflectivity of the second fiber Bragg grating 4 to 2.8 μm laser is greater than 99%, and the working bandwidth is less than 0.9 nm; the second fiber Bragg grating 4 and AlF 3 The end caps 8 together constitute the first optical resonant cavity of the 2.8 μm band fiber laser, and the generated laser with a wavelength of 2.8 μm is produced by AlF 3 End cap 8 output.

[0045] The pump laser 1 outputs pump light with a wavelength of 976nm, and the pump light is combined by a beam combiner 2 and then coupled into a double-clad erbium-doped fluoride fiber 5 .

[0046] Both the first Fiber Bragg Grating 3 and the third Fiber Bragg Grating 6 have a refl...

Embodiment 2

[0051] An erbium-doped fluoride fiber laser, the fiber laser comprising:

[0052] Such as figure 1 As shown, 976nm pump laser 1, beam combiner 2, first fiber Bragg grating 3, second fiber Bragg grating 4, double-clad erbium-doped fluoride fiber 5, third fiber Bragg grating 6, cladding mode stripper 7. AlF 3 end cap8.

[0053] The reflectivity of the second fiber Bragg grating 4 to 2.8 μm laser is greater than 99%, and the working bandwidth is less than 0.9 nm; the second fiber Bragg grating 4 and AlF 3 The end caps 8 together constitute the first optical resonant cavity of the 2.8 μm band fiber laser, and the generated laser with a wavelength of 2.8 μm is produced by AlF 3 End cap 8 output.

[0054] The pump laser 1 outputs pump light with a wavelength of 976nm, and the pump light is combined by a beam combiner 2 and then coupled into a double-clad erbium-doped fluoride fiber 5 .

[0055] Both the first Fiber Bragg Grating 3 and the third Fiber Bragg Grating 6 have a refl...

Embodiment 3

[0060] An erbium-doped fluoride fiber laser, the fiber laser comprising:

[0061] Such as figure 1 As shown, 976nm pump laser 1, beam combiner 2, first fiber Bragg grating 3, second fiber Bragg grating 4, double-clad erbium-doped fluoride fiber 5, third fiber Bragg grating 6, cladding mode stripper 7. AlF 3 end cap8.

[0062] The reflectivity of the second fiber Bragg grating 4 to 2.8 μm laser is greater than 99%, and the working bandwidth is less than 0.9 nm; the second fiber Bragg grating 4 and AlF 3 The end caps 8 together constitute the first optical resonant cavity of the 2.8 μm band fiber laser, and the generated laser with a wavelength of 2.8 μm is produced by AlF 3 End cap 8 output.

[0063] The pump laser 1 outputs pump light with a wavelength of 976nm, and the pump light is combined by a beam combiner 2 and then coupled into a double-clad erbium-doped fluoride fiber 5 .

[0064] Both the first Fiber Bragg Grating 3 and the third Fiber Bragg Grating 6 have a refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com