Continuous circulation flow crystallizer

A crystallizer and crystallization chamber technology, applied in solution crystallization, crystallization separation, evaporation separation crystallization, etc., can solve the problems of long operation time, easy explosive nucleation, temperature sensitivity, etc., to reduce production intensity and reduce equipment footprint and the effect of unit energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

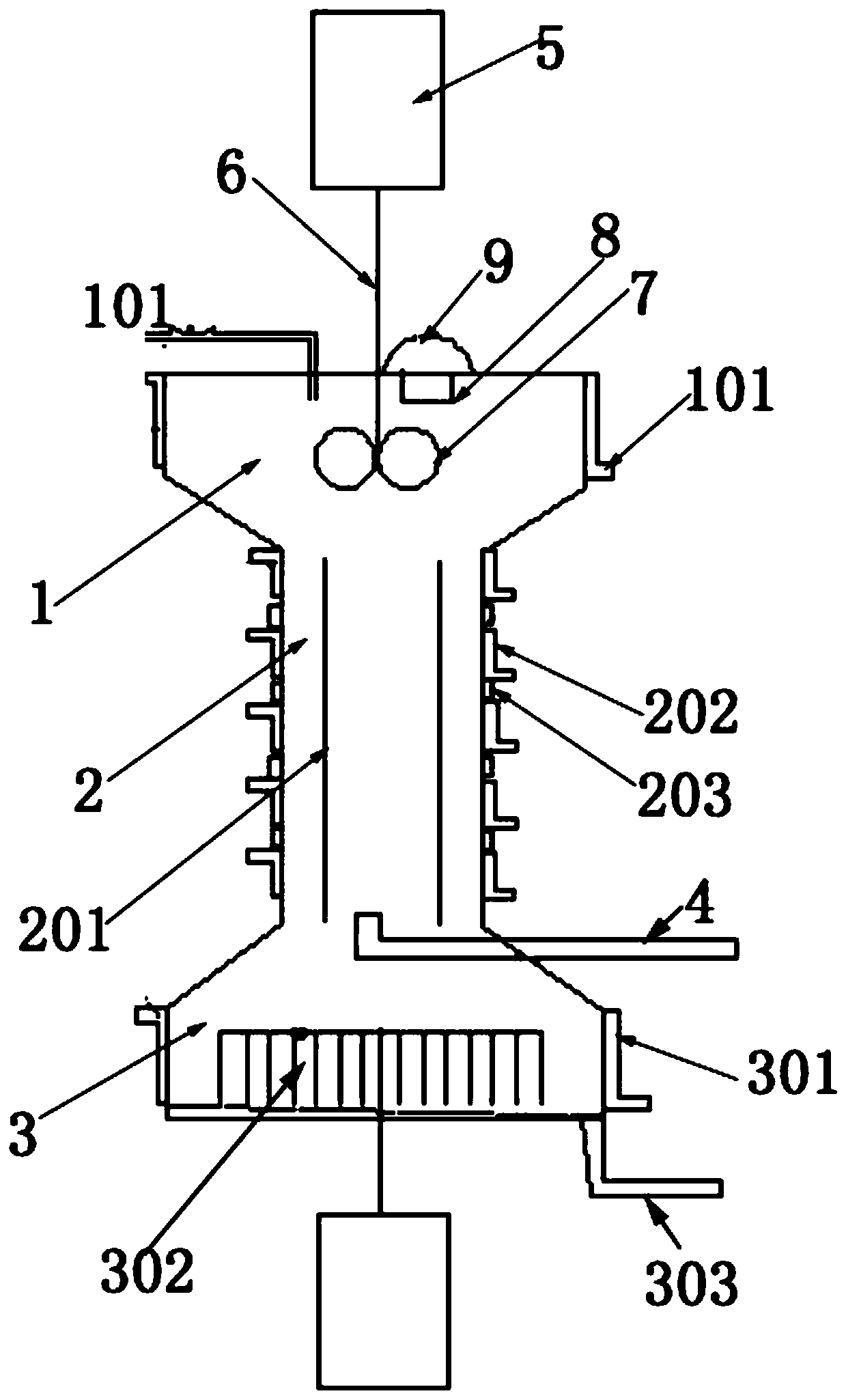

[0035] When utilizing the circulation continuous crystallizer of the present application to process the crystal liquid raw material liquid, the process is as follows:

[0036] The crystal liquid raw material liquid is fed with an aluminum sulfate aqueous solution with a temperature of 93°C and an aluminum sulfate mass concentration of 59.2%, and the temperature of the crystal liquid raw material liquid in the top heating chamber 1 is controlled by microwave heating to 95°C.

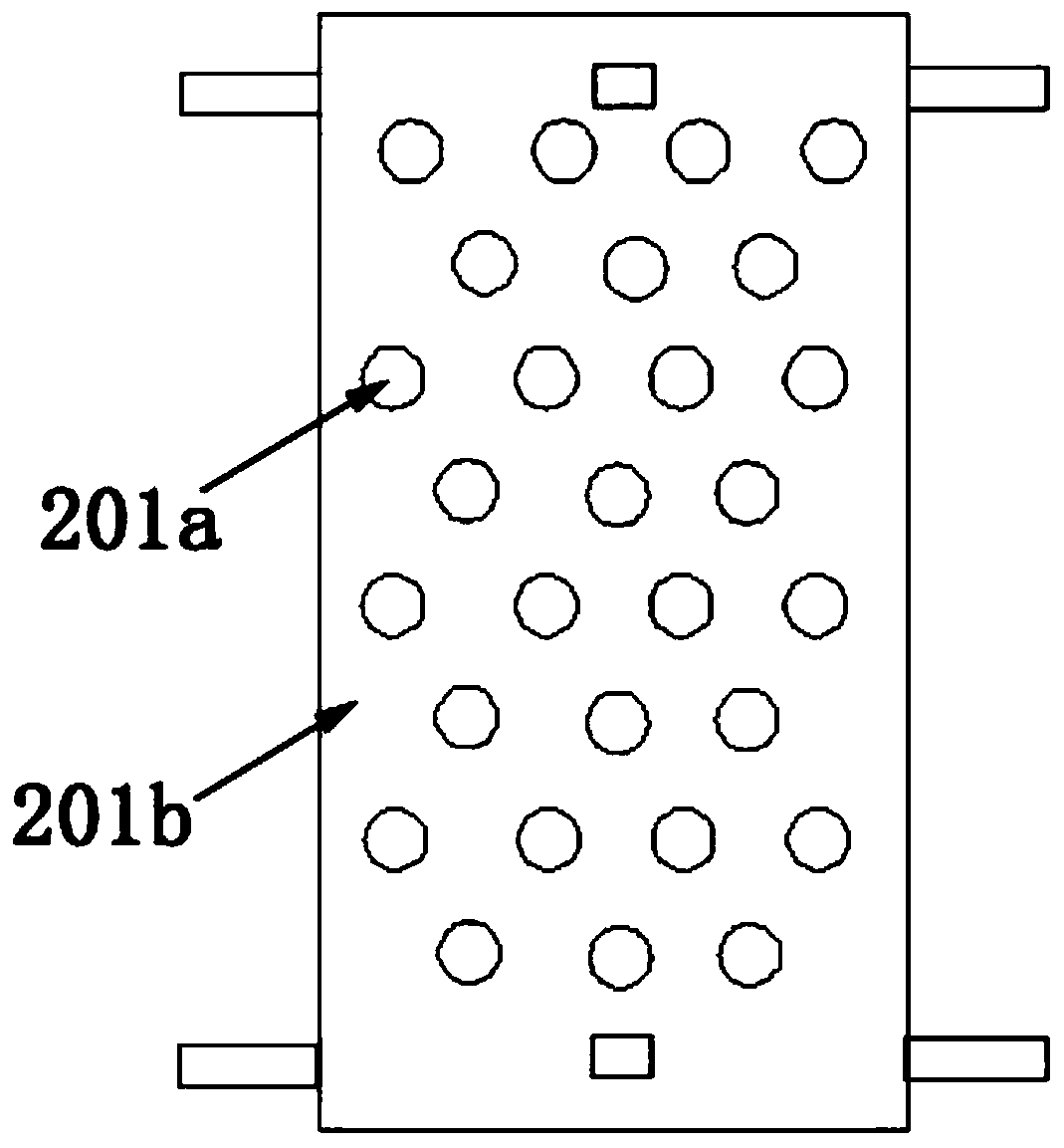

[0037] Seven heat exchange interlayers 202 are arranged at intervals from top to bottom on the outer side of the central crystallization chamber 2. The temperatures of the fluids fed into the upper five heat exchange interlayers 202 are respectively 94.5°C, 94°C, 93°C, 92°C and 90°C. The temperatures of the fluids fed into the lower two heat exchange interlayers 202 are respectively 75° C. and 40° C. respectively. Cooling fluid is passed into the cooling interlayer 301 outside the bottom crystal collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com