Photothermal catalytic carbon dioxide reaction detection apparatus and photothermal catalytic carbon dioxide reaction detection method

A technology of photothermal catalysis and carbon dioxide, applied in the direction of measuring devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as the inability to detect the conversion rate of photocatalytic products, achieve improved catalytic effects, accurate test results, and simple The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

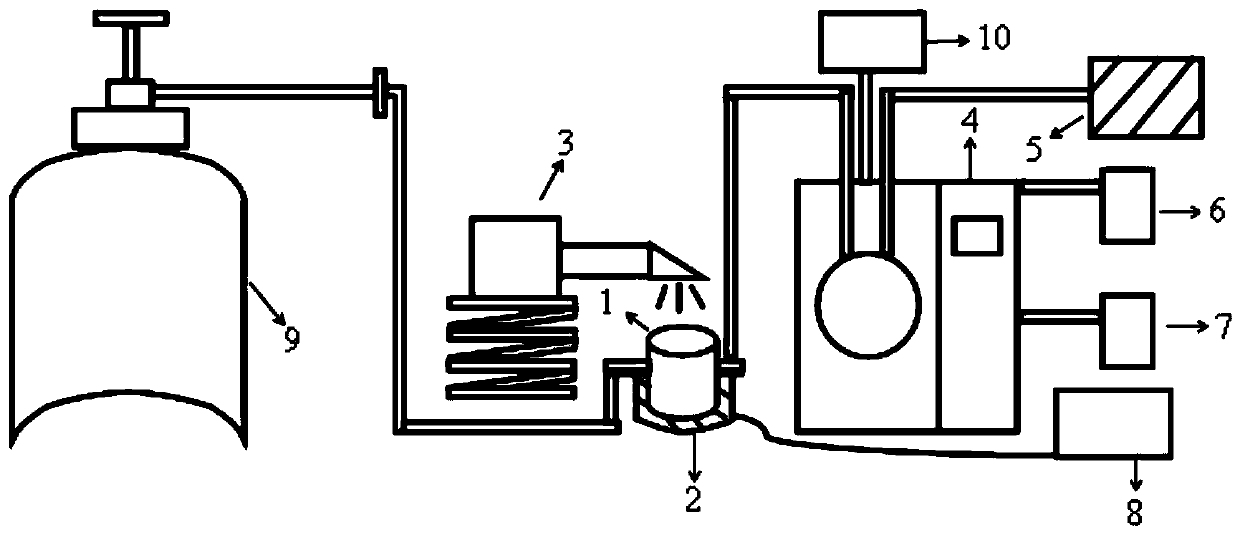

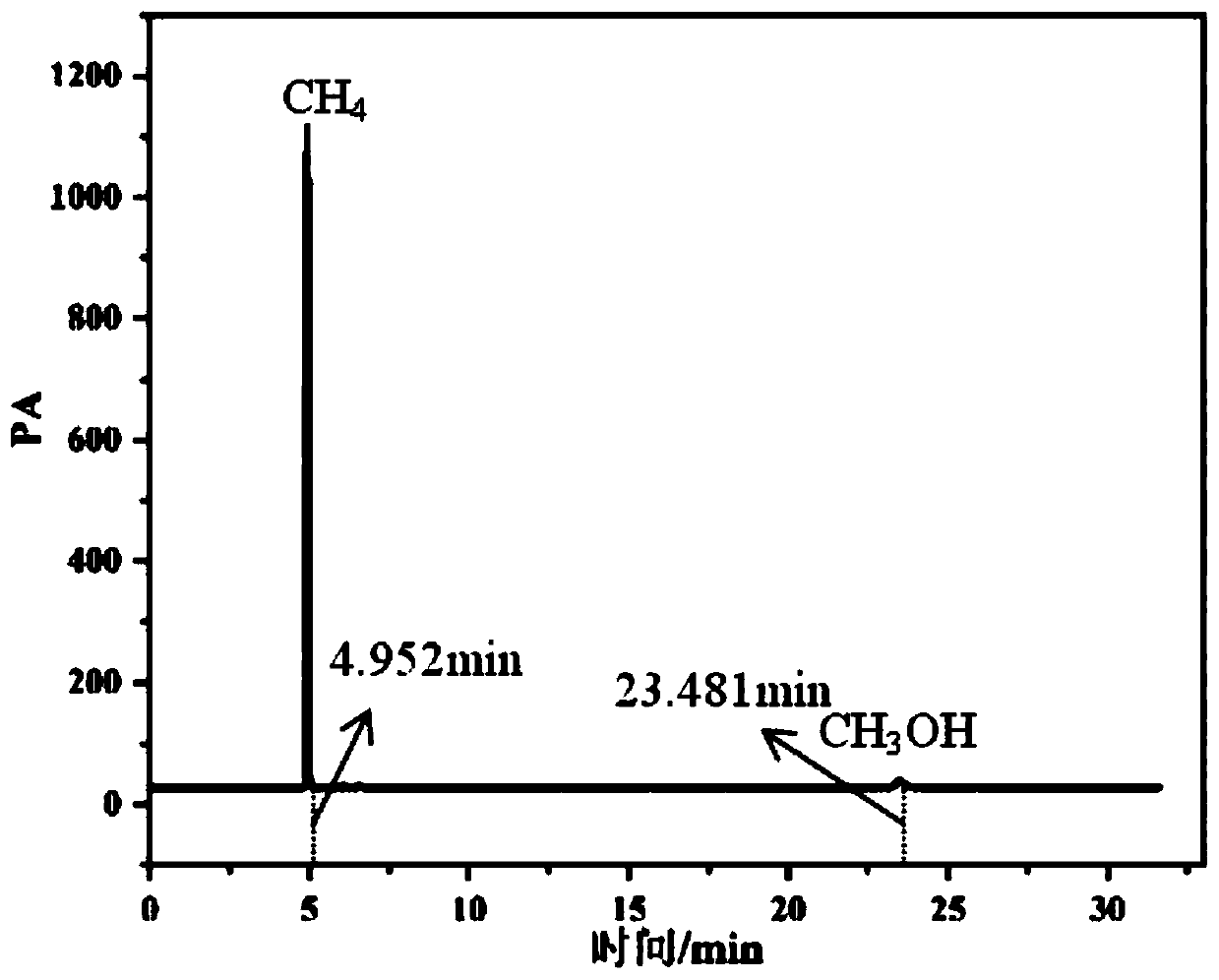

[0036] Such as figure 1 As shown, it is a photothermal catalytic carbon dioxide reaction detection device provided in this embodiment, which includes: a photothermal catalytic reactor 1, a heating device 2 for heating the photothermal catalytic reactor 1, and a photothermal catalytic reactor 1 for heating The catalytic reactor 1 provides the incident light source 3 of the light source, which is used to provide the photothermal catalytic reactor 1 with CO 2 CO 2 A gas source 9, a gas chromatograph 4 for detecting reactants produced in the photothermal catalytic reactor 1 and a detection system 5 for analyzing the detection data of the gas chromatograph 4; the gas chromatograph 4 is connected with Hydrogen generator 6, low noise pump 7 and N 2 Air source 10. A thermometer 8 is connected to the heating device 2 . The incident light source 3 is a xenon lamp.

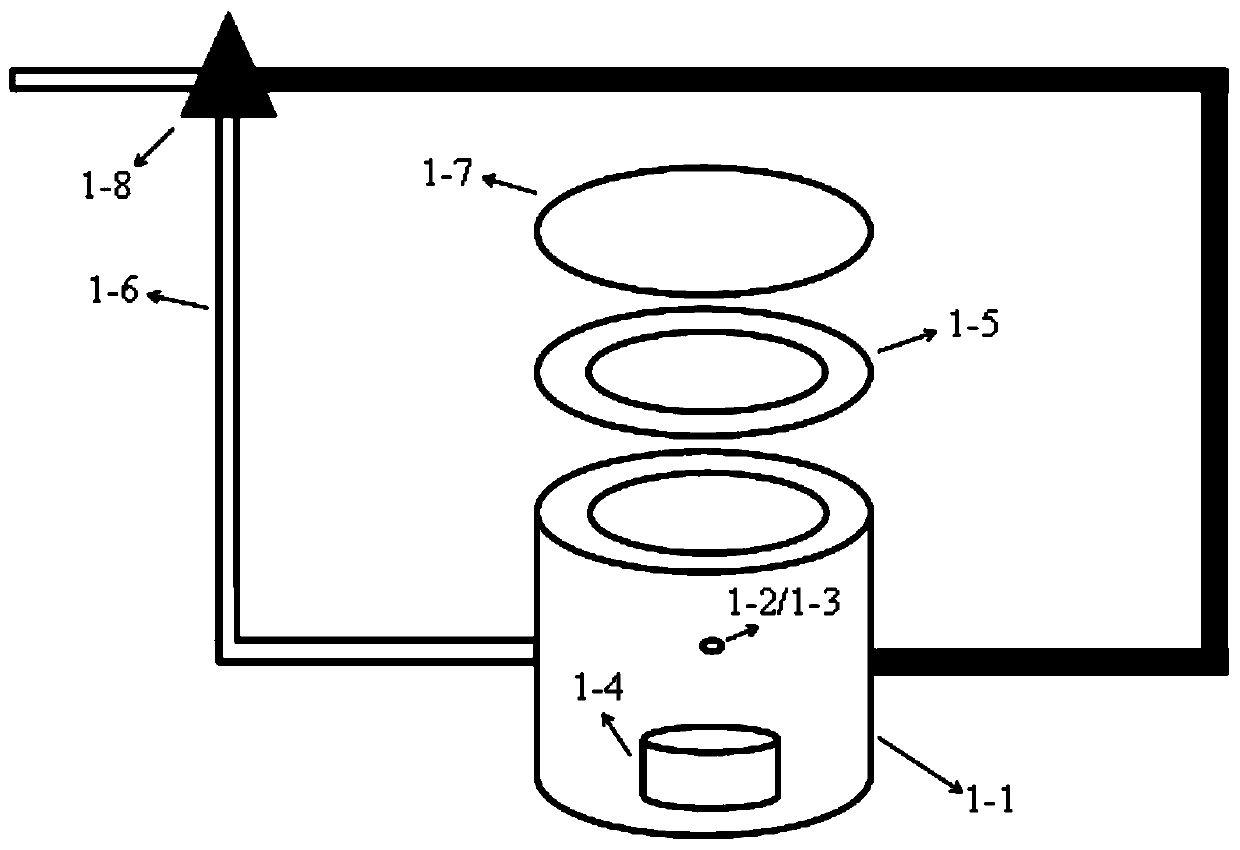

[0037] Such as figure 2 As shown, the photothermal catalytic reactor 1 includes a quartz reactor 1-1, the quartz re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com