Novel spindle box drive tension device and numerical control machine tool

A tensioning device and spindle box technology, applied to large fixed members, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of low efficiency, unadjustable spindle position of multi-axis spindle box, poor flexibility, etc., to ensure the structure , to meet the needs of high efficiency, compact and ingenious effect

Pending Publication Date: 2019-12-20

河北力准机械制造有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The first type of equipment is a single-axis machining center: its advantage is that it can change the tool and has good flexibility; the disadvantage is that it is single-axis processing and low in efficiency; the second type of equipment is a rigid multi-axis special machine tool: its advantage is multi-axis and multi-tool simultaneous processing, High efficiency; the disadvantage is that the position of the main shaft of the multi-axis headstock box is not adjustable, and the flexibility is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0040] This embodiment provides a numerically controlled machine tool. The new headstock driving and tensioning device described in Embodiment 1 is installed on the main control machine tool; the headstock installed at the end of the input shaft is a multi-axis headstock.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

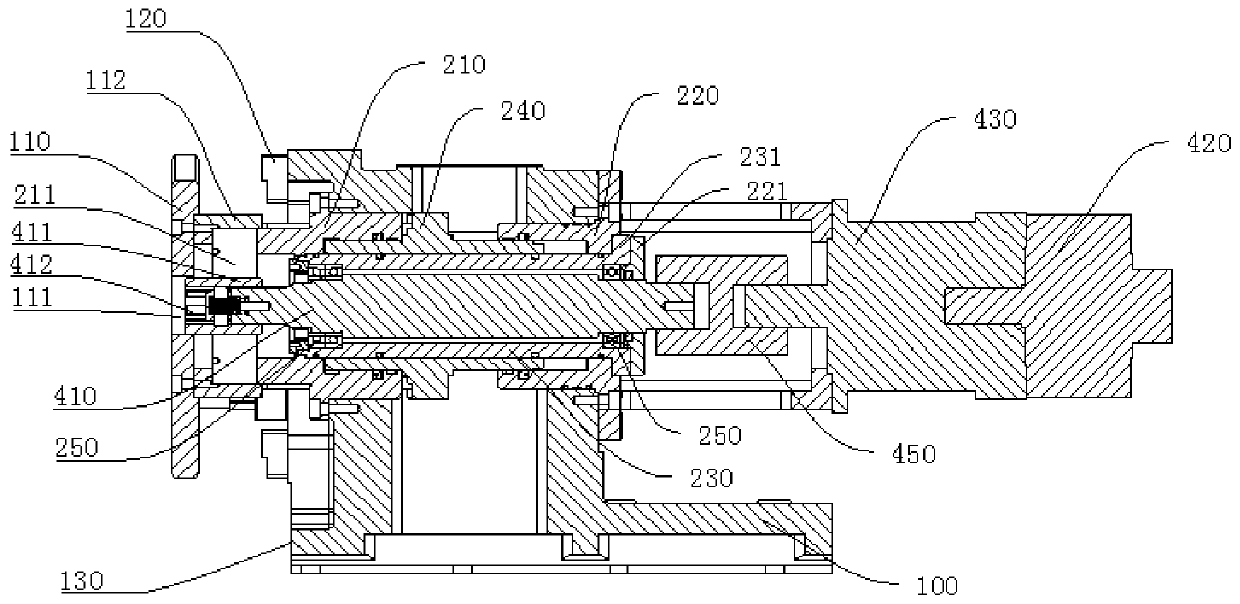

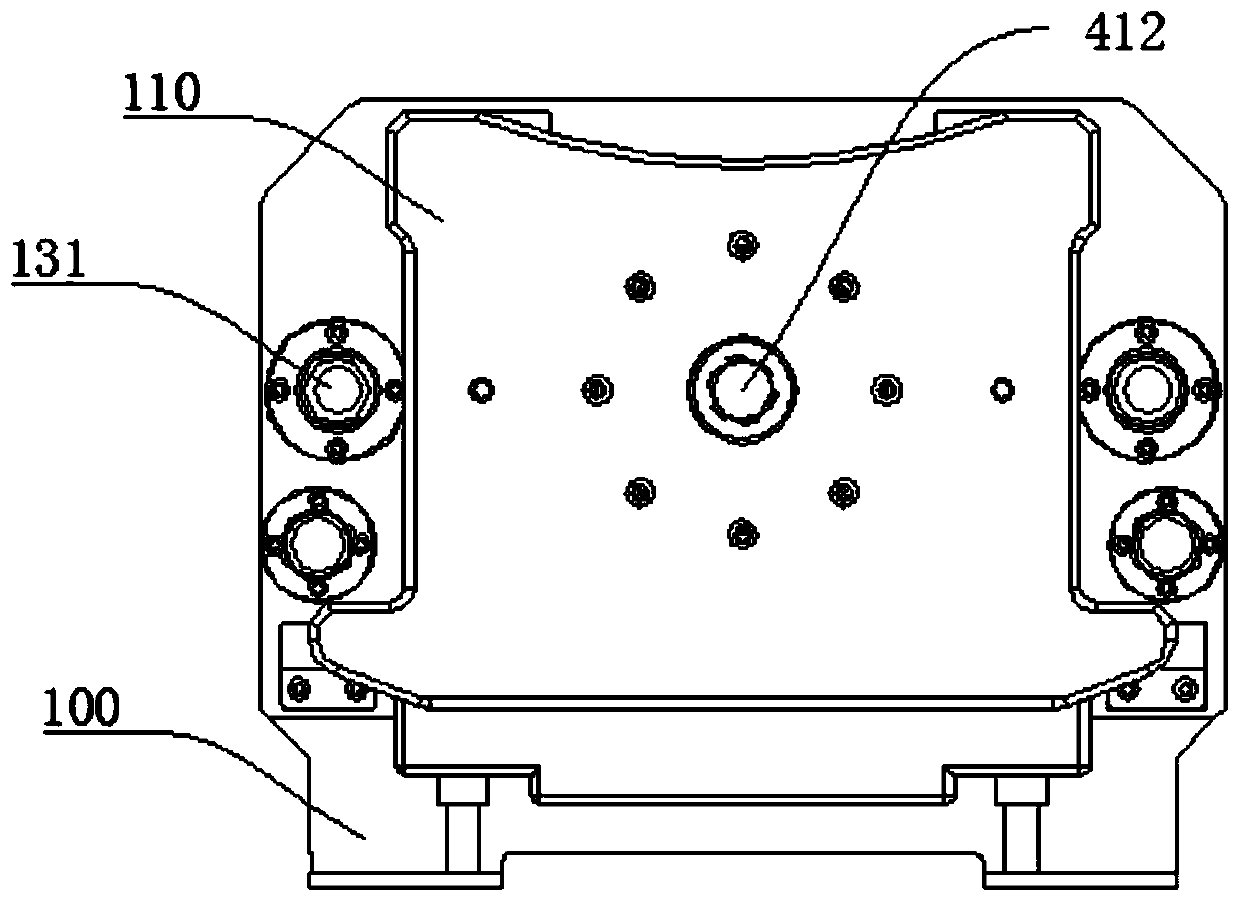

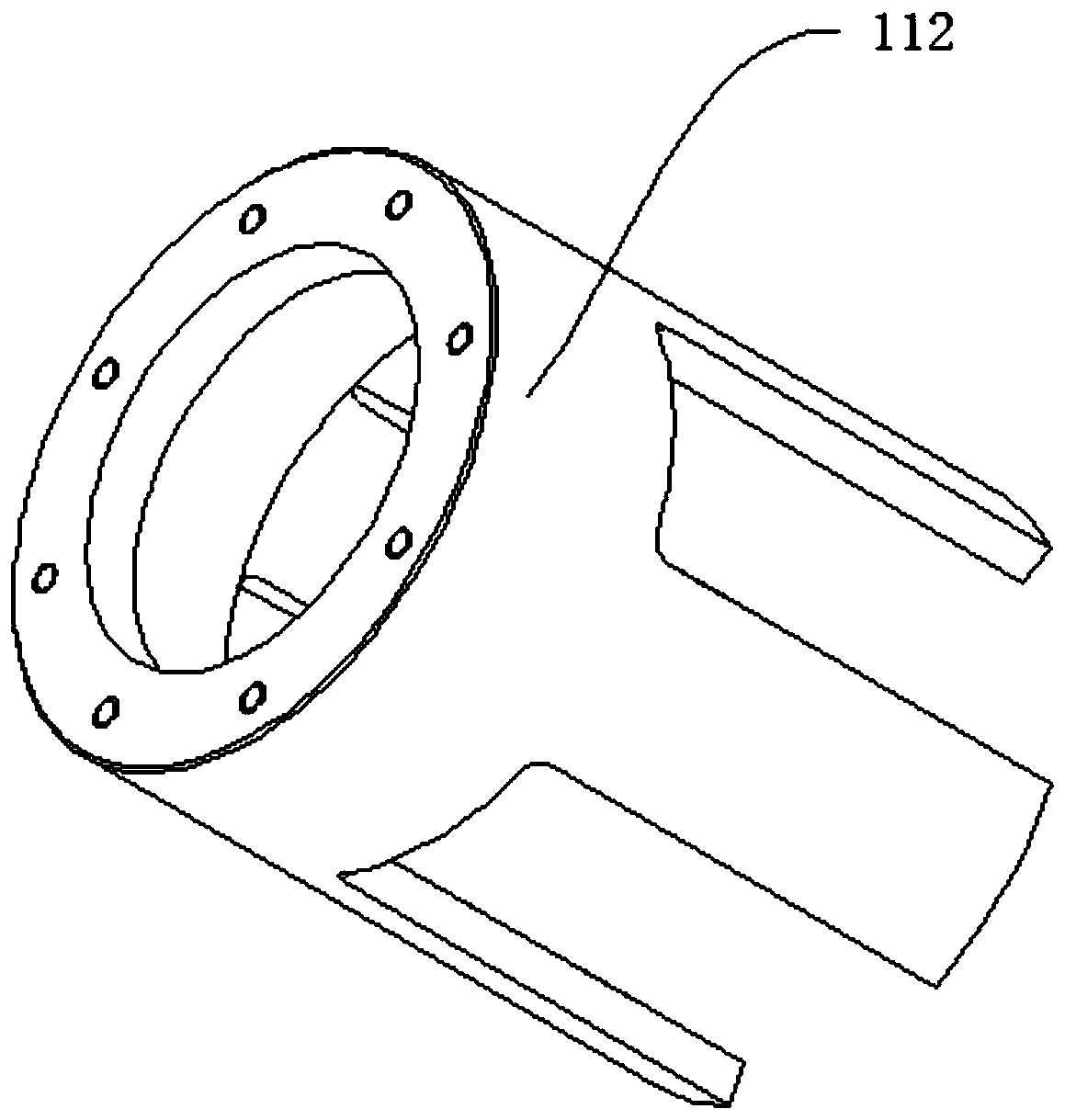

The invention discloses a novel spindle box drive tension device and a numerical control machine tool. The tension device comprises a mechanism body and a split type oil cylinder fixed to the mechanism body, the split type oil cylinder comprises a front cylinder barrel, a rear cylinder barrel, a hollow input shaft sleeve and a hollow piston, the front cylinder barrel and the rear cylinder barrel are fixed to the mechanism body, the hollow input shaft sleeve and the hollow piston are arranged in the front cylinder barrel and the rear cylinder barrel, the two ends of the input shaft sleeve are fixedly connected with the inner walls of the front cylinder barrel and the rear cylinder barrel correspondingly, the input shaft sleeve is sleeved with the piston, the side, away from the rear cylinder barrel, of the front cylinder barrel is vertically provided with a tension plate used for fixing a spindle box, the side, facing the front cylinder barrel, of the tension plate is fixedly connectedwith a tension sleeve, the part, between the front cylinder barrel and the rear cylinder barrel, of the piston protrudes outwards and is fixedly connected with the tension sleeve, and the tension plate is driven to move; an input shaft is connected into the input shaft sleeve through a bearing, and one end of the input shaft is connected with a driving mechanism for driving the input shaft to rotate; and high-efficiency needs of rigid multi-shaft machining of a machining device can be met, and convenience is brought to spindle box replacing.

Description

technical field [0001] The present disclosure generally relates to the technical field of machine tool processing, and specifically relates to a novel headstock drive tensioning device and a numerically controlled machine tool. Background technique [0002] Due to the need for work, I have a detailed understanding of the existing automotive and motorcycle parts processing equipment market, and found that there are basically two types of automotive and motorcycle gearbox housing processing equipment in the market. The first type of equipment is a single-axis machining center: its advantage is that it can change the tool and has good flexibility; the disadvantage is that it is single-axis processing and low in efficiency; the second type of equipment is a rigid multi-axis special machine tool: its advantage is multi-axis and multi-tool simultaneous processing, High efficiency; the disadvantage is that the position of the main shaft of the multi-axis headstock box cannot be adj...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23B19/00

CPCB23Q1/70

Inventor 王爱华张文平罗二龙

Owner 河北力准机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com