Nitrogen fixation device used in multi-element activated nitrogen arc welding process and method

A welding process, nitrogen arc technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as uneven distribution of alloy elements, deterioration of welding process performance, poor cladding quality, etc., to achieve simple operation and improve welding Process performance, the effect of overcoming directionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

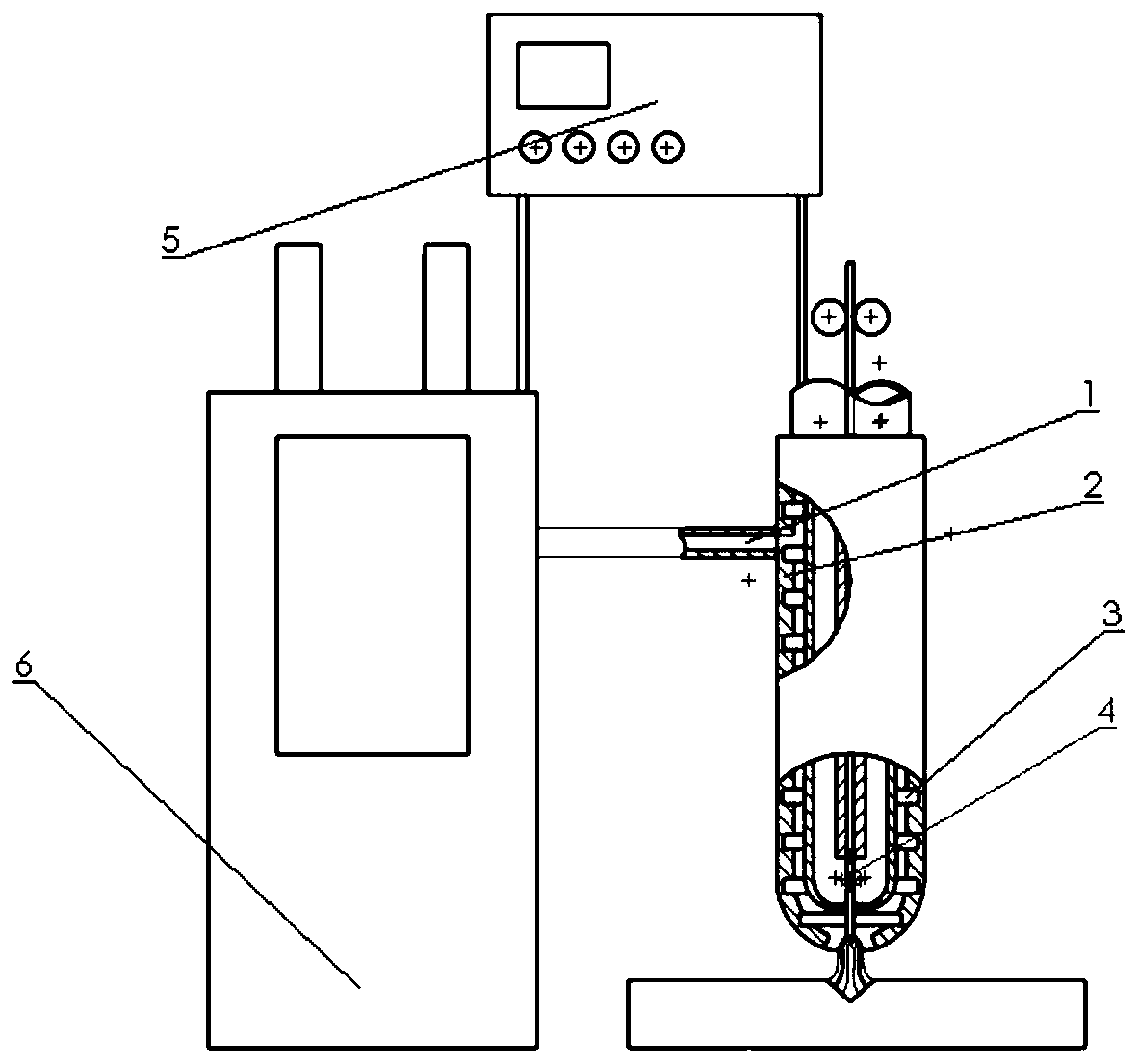

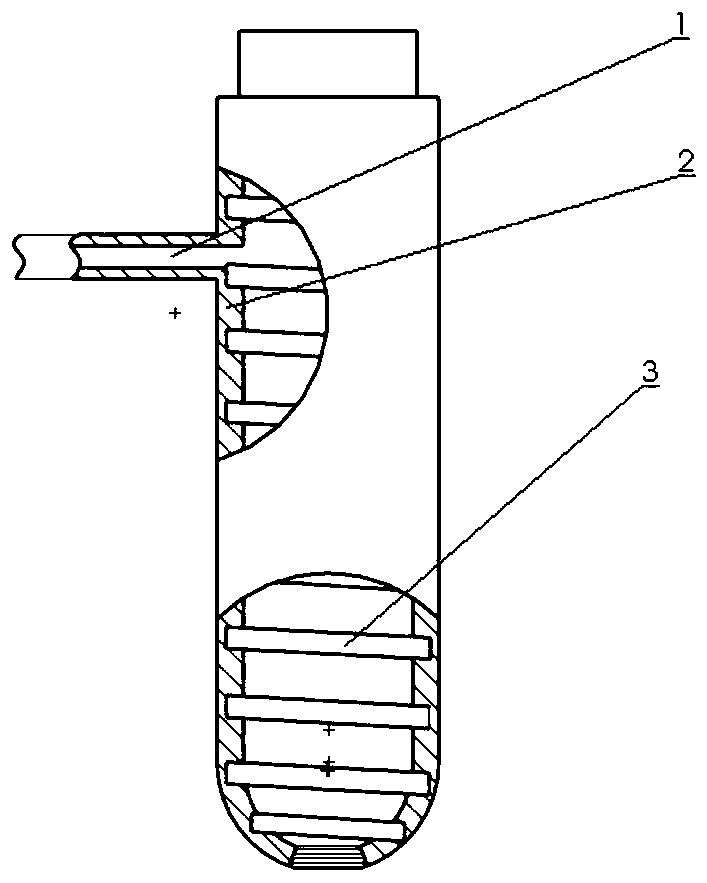

Embodiment 1

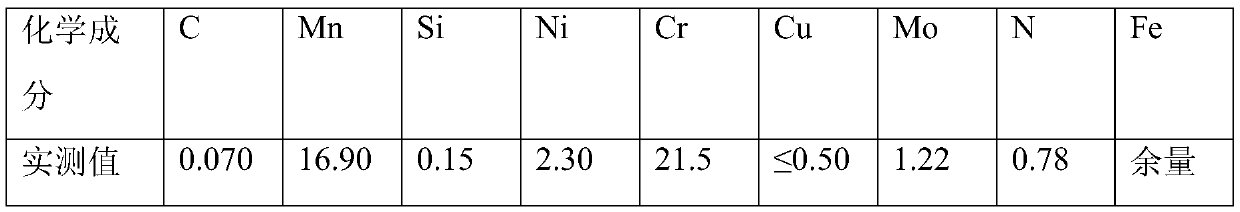

[0052] There is a V-shaped groove on the high-nitrogen austenitic stainless steel, the groove angle is 90°, and the size of the high-nitrogen steel plate is 400mm×120mm×10mm. figure 1 The shown device adopts a nitrogen fixation method in a multi-component activated nitrogen arc welding process to form a weld seam with nitrogen content meeting the requirements. The high-nitrogen steel welding wire used is self-made welding wire HNS6T2, the chemical composition is shown in Table 1, and the target composition of the high-nitrogen steel layer is shown in Table 2.

[0053] Table 1 HNS6T2 welding wire chemical composition (%)

[0054]

[0055] Table 2 Chemical composition requirements of target high nitrogen steel welds (%)

[0056]

[0057] Adopt the nitrogen fixation method in the multiple activation nitrogen arc welding process of the present invention, its concrete steps are:

[0058] Step 1, through the target alloy composition of the high-nitrogen steel weld, determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com