Polypropylene hollow resin particles and its extrusion mechanism and hollow expanded polypropylene beads

A technology of resin particles and polypropylene, which is applied in the field of extrusion mechanism, can solve the problems of uneven discharge, filament adhesion, and inability to obtain middle holes, etc., and achieve convenient extrusion expansion ratio, small cross-sectional area, and good appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

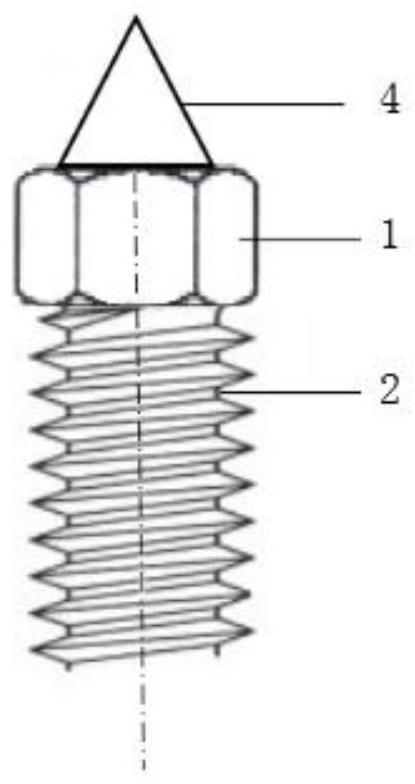

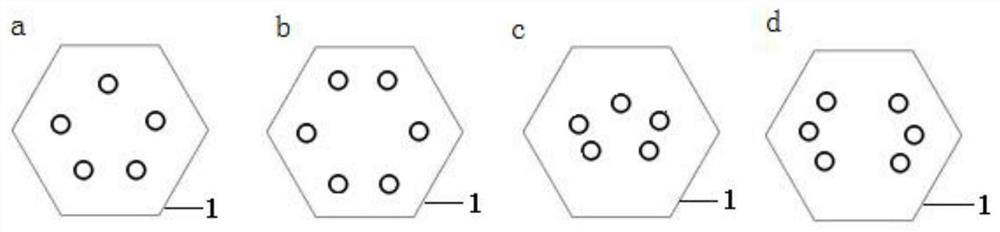

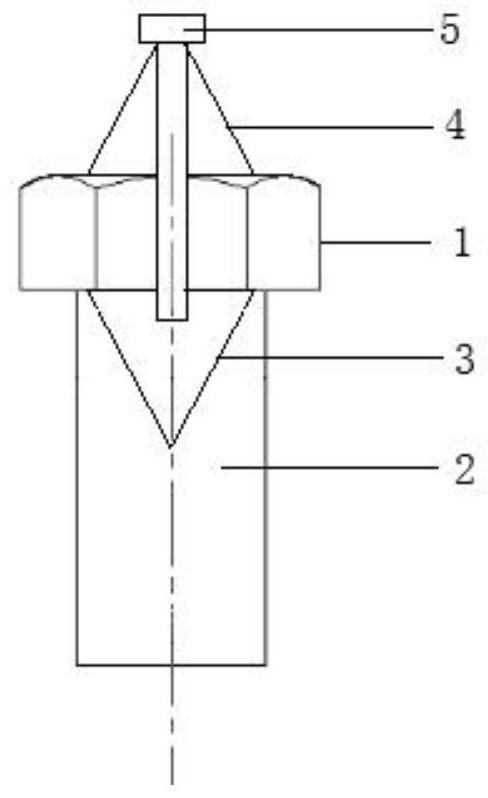

[0046] Step 1. Mix 100 parts by weight of polypropylene resin, 5 parts by weight of color masterbatch, 0.5 parts by weight of lubricant and 0.5 parts by weight of nucleating agent in a high-speed mixer, and then mix them uniformly through screw extrusion process. Extruded in the polypropylene hollow resin particle extrusion mechanism of the conventional head plate of the extruder, the filaments on the same extrusion mechanism are fused together to form hollow PP filaments, and the filaments are introduced into the cold water tank for cooling Solidify and pelletize to obtain polypropylene hollow resin particles.

[0047] Step 2: Add 100 parts by weight of polypropylene hollow resin particles, 250 parts by weight of water, 0.05 parts by weight of surfactant (sodium dodecylbenzenesulfonate) and 0.5 parts by weight of kaolin into an 800L autoclave, heat and pressurize, Until the foaming temperature and foaming pressure are reached, the foaming pressure is maintained at the foaming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com