Microbial fuel cell for oil sludge treatment and synchronous reduction of soil hexavalent chromium

A fuel cell, hexavalent chromium technology, applied in sludge treatment, electrochemical sludge treatment, restoration of polluted soil, etc., can solve the problems of complex process, long treatment time, high treatment cost, and achieve high reduction efficiency, Low cost to build and operate, easy to manage and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

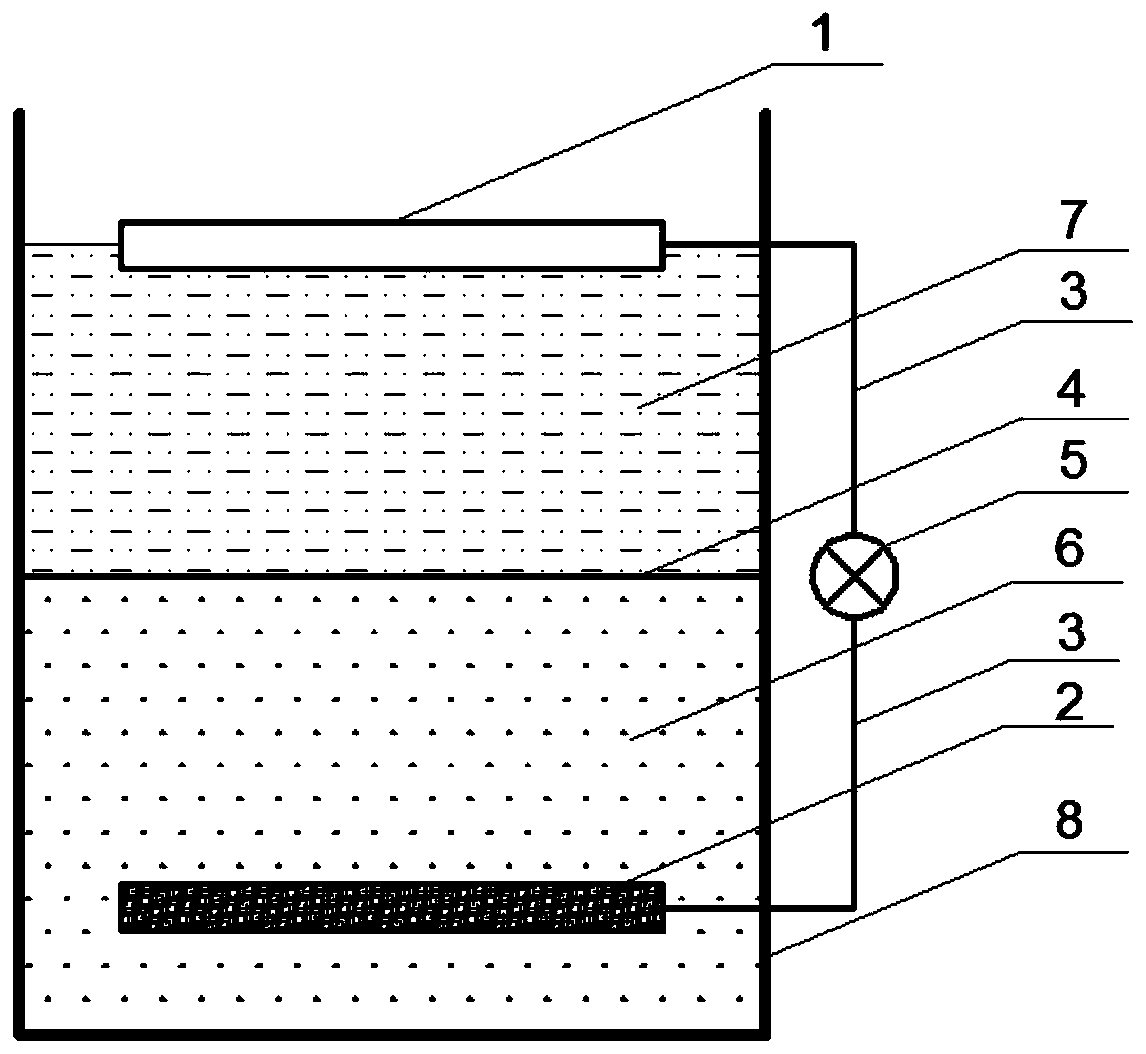

[0025]The housing 8 is provided with oily sludge 6 (thickness is 10cm) and hexavalent chromium-contaminated soil 7 (thickness is 10c). It comes from the heaping site. The housing 8 has a diameter of 15 cm and a height of 30 cm, and is made of plastic material. The cathode 1 is placed on the upper part of the hexavalent chromium-contaminated soil, which is a graphite plate with a length of 10 cm, a width of 10 cm, and a thickness of 0.5 cm. The anode 2 is placed in the oil sludge at the bottom of the housing 8, 20 cm below the cathode, and the anode is an open-cell foam carbon with a length of 10 cm, a width of 10 cm, and a thickness of 0.5 cm. A proton exchange membrane 4 is arranged between the cathode 1 and the anode 2, so that the protons generated by the anode migrate to the surface of the cathode through the proton exchange membrane. The cathode 1 and the anode 2 are connected to a resistor or electrical equipment 5 through a wire 3, the wire 3 is a copper wire; the res...

Embodiment 2

[0028] Housing 8 is provided with oily sludge 6 (thickness is 8cm) and hexavalent chromium-contaminated soil 7 (thickness is 8cm). It comes from the heaping site. The housing 8 has a diameter of 15 cm and a height of 25 cm, and is made of plastic material. The cathode 1 is placed on the upper part of the hexavalent chromium-contaminated soil, which is a graphite plate with a length of 5 cm, a width of 5 cm, and a thickness of 0.3 cm. The anode 2 is placed in the oil sludge at the bottom of the housing 8, 16 cm below the cathode, and the anode is an open-cell foam carbon with a length of 5 cm, a width of 5 cm, and a thickness of 0.3 cm. A proton exchange membrane 4 is arranged between the cathode 1 and the anode 2, so that the protons generated by the anode migrate to the surface of the cathode through the proton exchange membrane. The cathode 1 and the anode 2 are connected to the resistor or the electrical equipment 5 through the wire 3, and the wire 3 is a copper wire; the...

Embodiment 3

[0031] The housing 8 is provided with oily sludge 6 (20 cm in thickness) and hexavalent chromium-contaminated soil 7 (20 cm in thickness). It comes from the heaping site. The housing 8 has a diameter of 35cm and a height of 50cm, and is made of plastic material. The cathode 1 is placed on the upper part of the hexavalent chromium-contaminated soil, which is a graphite plate with a length of 25 cm, a width of 25 cm, and a thickness of 0.8 cm. The anode 2 is placed in the oil sludge at the bottom of the housing 8, 40 cm below the cathode, and the anode is an open-cell foam carbon with a length of 25 cm, a width of 25 cm, and a thickness of 0.8 cm. A proton exchange membrane 4 is arranged between the cathode 1 and the anode 2, so that the protons generated by the anode migrate to the surface of the cathode through the proton exchange membrane. The cathode 1 and the anode 2 are connected to the resistor or the electrical equipment 5 through the wire 3, and the wire 3 is a copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com