Water-cooled closed sludge drying system and temperature control method thereof

A temperature control method and sludge drying technology, applied in dehydration/drying/concentrated sludge treatment, refrigeration and liquefaction, refrigerators, etc., can solve problems such as low reliability, complicated control, and poor control accuracy, and achieve Stable drying temperature, high control precision and high control reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

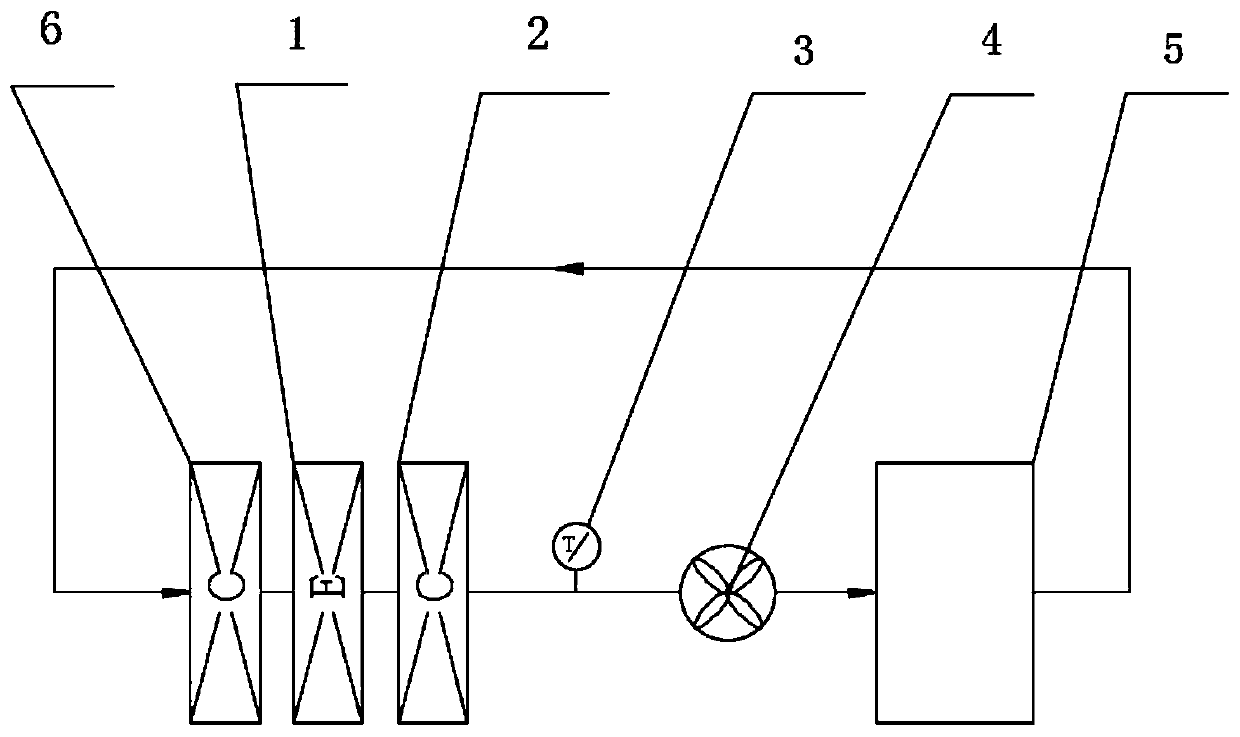

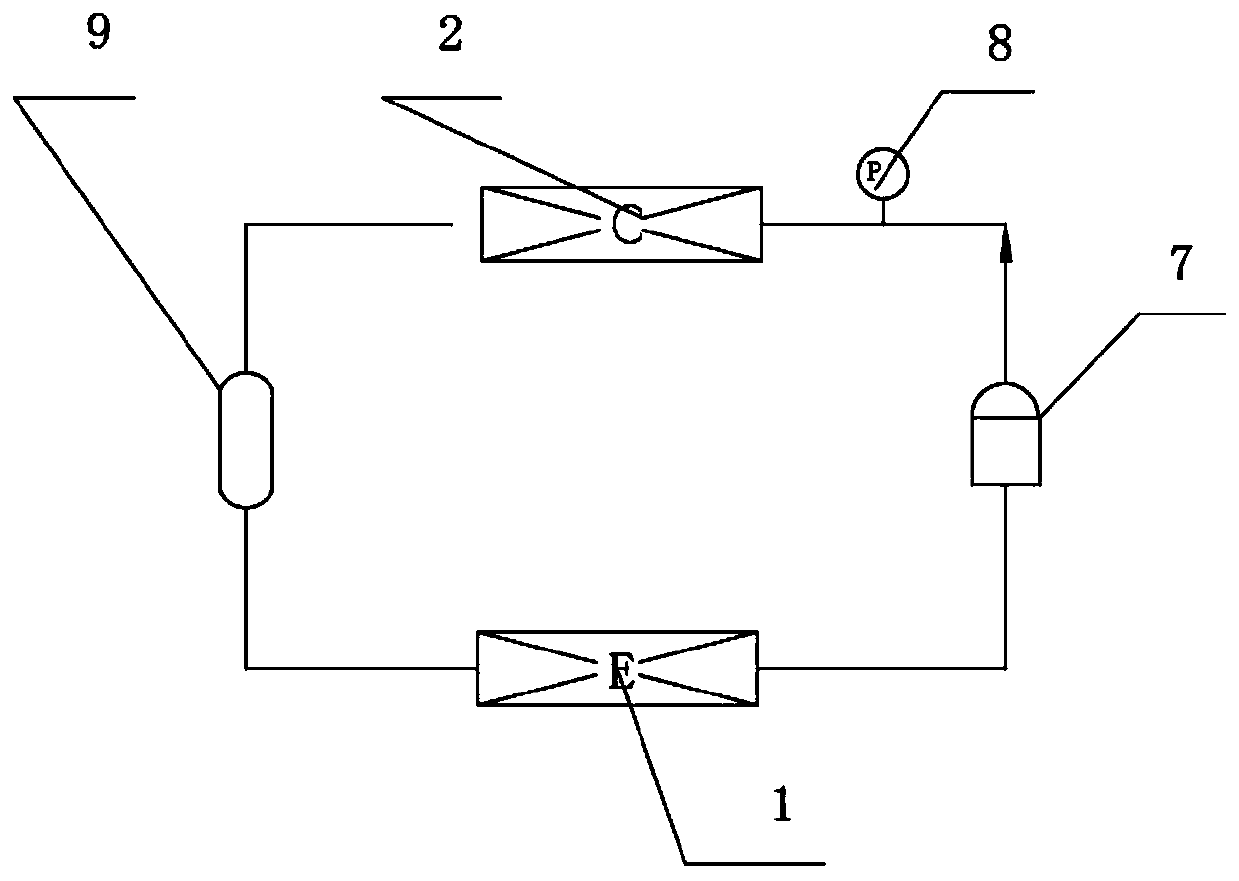

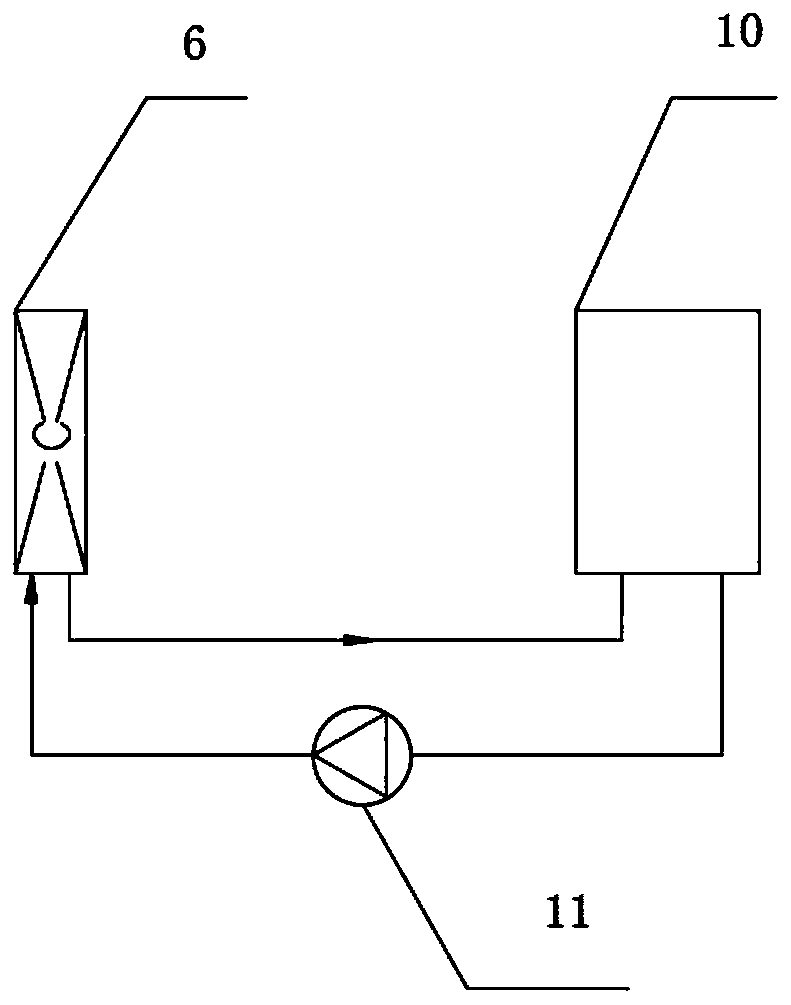

[0030] Please refer to Figure 1-3 As shown, the embodiment of the present invention discloses a water-cooled closed sludge drying system, including a drying box 5, a main fan 4, a main condenser 2, an evaporator 1 and a water cooler 6, and the water cooler 6. The evaporator 1, the main condenser 2, the main fan 4 and the drying box 5 are connected through the air guide pipeline to form a closed cycle drying circuit. The water-cooled closed sludge drying system also includes a compressor 7, The compressor 7 , the main condenser 2 and the evaporator 1 are connected through a refrigerant pipeline to form a closed cycle refrigerant circuit, and the water cooler 6 is connected to the water pump 11 and the cooling water tower 10 to form a temperature regulation circuit. A temperature detector 3 is provided between the main condenser 2 and the main fan 4, and the temperature detector 3 is used to detect the temperature of the air coming out of the main condenser 2 to enter the dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com