Aerobic composting reaction device

A reaction device and composting technology, applied in the field of biomass, can solve the problems of inconvenient research on the operation parameters of the reaction mechanism of aerobic composting, and achieve the effects of easy use, easy replacement of parts, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

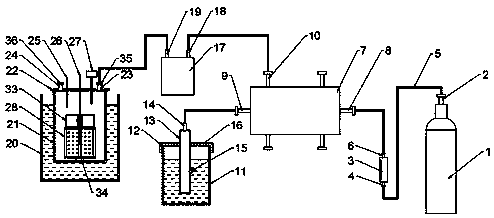

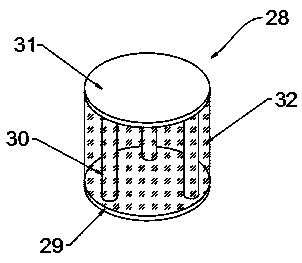

[0024] Embodiment one, by figure 1 and figure 2 Given, the present invention comprises oxygen cylinder 1, and pressure valve 2 is installed on the upper end of oxygen cylinder 1, and one side of oxygen cylinder 1 is connected with float flowmeter 3, and one end of float flowmeter 3 is connected with float flowmeter air inlet 4, and float flowmeter The air inlet 4 is connected to the pressure valve 2 through the air pipe 5, the other end of the float flow meter 3 is connected to the air outlet 6 of the float flow meter, one end of the float flow meter 3 is connected to the air exhaust 7, and the two ends of the air exhaust 7 are respectively connected to the air exhaust inlet. Air port 8 and air exhaust port 9, the air exhaust inlet 8 is connected to the air outlet 6 of the float flowmeter through the air pipe 5, the upper end of the air exhaust 7 is connected to the air distribution port 10, and the side of the air exhaust 7 is connected to the bypass bottle 11, the bypass T...

Embodiment 2

[0025] Embodiment 2, on the basis of Embodiment 1, a through hole is opened in the middle of the upper end of the threaded cover 12, the voltage stabilizing rod 13 is located in the through hole, and a connecting ring is embedded between the voltage stabilizing rod 13 and the contact end of the through hole, so as to facilitate the The rod 13 is plugged into the screw cap 12 .

Embodiment 3

[0026] Embodiment 3, on the basis of Embodiment 1, the outer wall of the upper end of the bypass bottle 11 is provided with an external thread that is conveniently connected with the threaded cap 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com