0.0% vol alcohol-free Lager beer and preparation method thereof

A technology of beer and hops, applied in the field of alcohol-free Lager beer with an alcohol content of 0.0% and its preparation, which can solve the problems of lack of traditional beer alcohol ester flavor, prominent sour feeling, and light taste, and achieve good drinkability and sour feeling Balanced, high nutritional value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

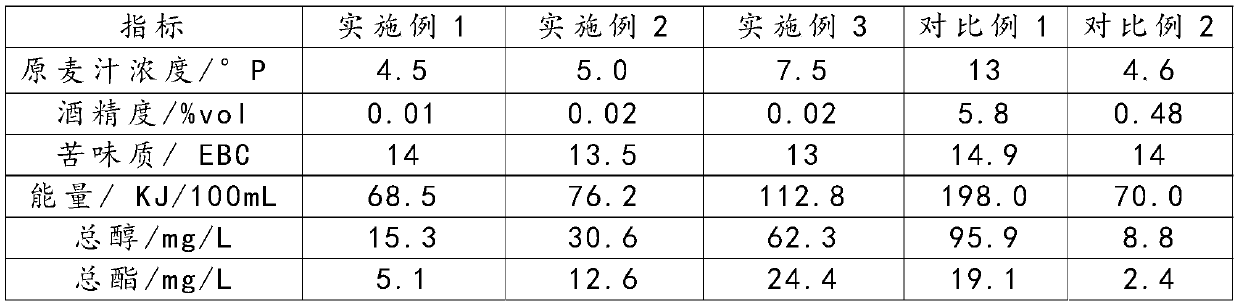

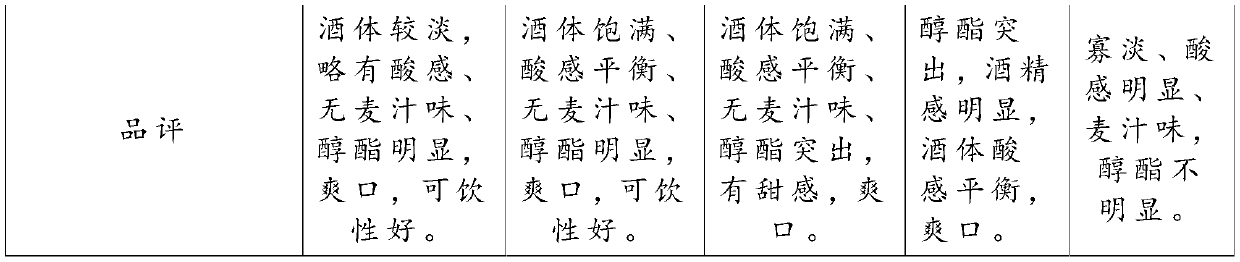

Embodiment 1

[0061] The classic Lager beer is preheated, degassed, dealcoholized (alcohol < 0.05% vol), cooled (cooled to 0-4°C), filled with carbon dioxide (cooled to 0-4°C), post-modified (adding 0.05% Non-alcoholic natural beer flavors containing alcohol esters, wheat fragrance and other substances, adding 0.1g (calculated by sugar content) of natural sweetness component sucrose, the true concentration of non-alcoholic beer reaches 4.5°P), filtered, stabilized (stable for more than 4h), In the filling step, 0.0% vol non-alcoholic Lager beer is prepared.

Embodiment 2

[0063] The classic Lager beer is preheated, degassed, dealcoholized (alcohol content <0.05% vol), cooled (cooled to 0-4°C), filled with carbon dioxide (cooled to 0-4°C), post-modified (adding 0.1% The non-alcoholic natural beer essence containing alcohol ester, wheat flavor and other substances, adding 0.6g (in terms of sugar content) natural sweetness ingredients (80% maltose syrup), the true concentration of non-alcoholic beer reaches 5.0°P), filtered, stabilized ( Stable for more than 4h), filling steps, to prepare 0.0% vol alcohol-free Lager beer.

Embodiment 3

[0065] The classic Lager beer is preheated, degassed, dealcoholized (alcohol content <0.05% vol), cooled (cooled to 0-4°C), filled with carbon dioxide (cooled to 0-4°C), post-modified (adding 0.2% The non-alcoholic natural beer essence containing alcohol ester, wheat flavor and other substances, add 3.1g (by sugar amount) natural sweetness component (80% malt syrup), the true concentration of non-alcoholic beer reaches 7.5°P), filter, stabilize ( Stable for more than 4h), filling steps, to prepare 0.0% vol alcohol-free Lager beer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com