Composition containing low-voc, aminoalkyl-functional silicon compounds for coating colours for the treatment of paper or film

A technology for polysilylation of aminoalkyl functions and aminoalkyl functions, which can be used in paper coatings, fiber raw material treatment, coatings, etc., and can solve problems such as high environmental burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

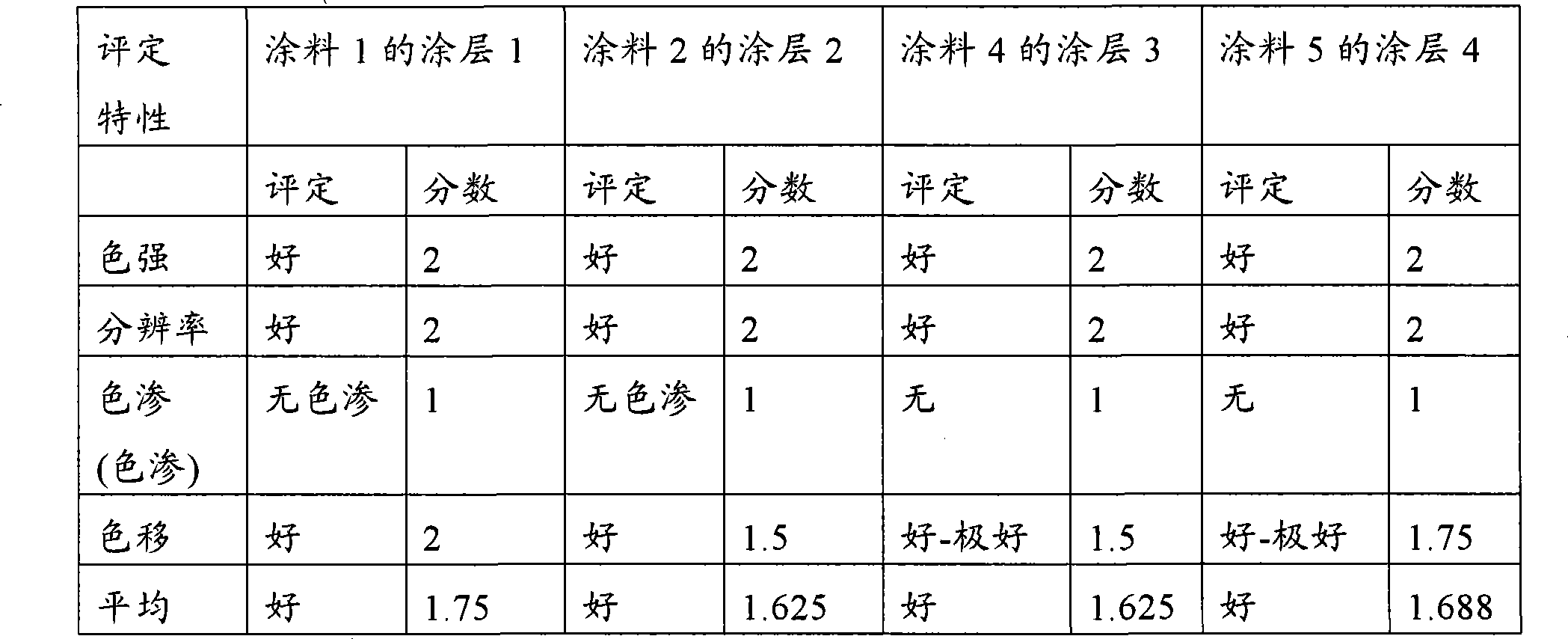

Image

Examples

Embodiment 1

[0131] Compositions with reduced VOC content

[0132] In a stirring device equipped with a metering device and a reflux condenser, 470.6 g of 1189 [N-(n-butyl)-3-aminopropyltrimethoxysilane, manufacturer: Degussa GmbH] and 80.0 g methanol. Then metered in 10 minutes by metering equipment by 28.8g H 2 The mixture of O and 28.8g methanol (molar hydrolysis ratio Si:H 2 O=1:0.8. The temperature rose from 28°C to 50°C. Stir at about 60°C for 3 hours. Then 208.89 g of methanol were distilled off at about 200 mbar. The residue / product weight was 394.87 g.

[0133] A storage-stable light yellow transparent liquid was obtained.

[0134] SiO 2 -Content: 29.6% (mass)

[0135] Methanol (after hydrolysis): 19.5% (mass)

[0136] Viscosity (20℃): 26mPas

[0137] Density (20℃): 0.996g / cm 3

Embodiment 2

[0139] Compositions with reduced VOC content

[0140] In a stirring device equipped with a metering device and a reflux condenser, 470.6 g of 1189 and 80.0 g methanol. Then add 43.20g of H in 10 minutes through metering equipment 2 A mixture of O and 43.20 g methanol (molar hydrolysis ratio Si:H2O=1:1.2). The temperature rose from 28°C to 56°C. Stir at about 60°C for 3 hours. Then 263.50 g of methanol were distilled off at about 200 mbar. The residue / product weight was 357.77 g.

[0141] A storage-stable light yellow transparent viscous liquid was obtained.

[0142] SiO 2 -Content: 32.0% (mass)

[0143] Methanol (after hydrolysis): 9.2% (mass)

[0144] Viscosity (20℃): 187mPas

[0145] Density (20℃): 1.027g / cm 3

Embodiment 3

[0147] Substantially VOC-free composition

[0148] 498.2 g of water and 55.0 g of formic acid (HCOOH concentration=85%) were charged under a nitrogen atmosphere in a stirring apparatus equipped with a metering device and a reflux condenser. Then add 235.7g through metering equipment 1189. The pH is 4.8. Stir at 60°C for 3 hours. The methanol / water mixture is then distilled off at about 130-200 mbar. The residue weight was 589.0 g.

[0149] A light yellow transparent liquid with a pH value of 5.3 was obtained which was stable in storage.

[0150] SiO 2 -Content: 9.2% (mass)

[0151] Ignition point: >100℃

[0152] Free methanol: 0.5% (mass)

[0153] Viscosity (20℃): 11mPas

[0154] Density (20℃): 1.070g / cm 3

[0155] Dry residue 105°C: 36.2% (mass)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com