A Method of Improving Local Comprehensive Mechanical Properties of High Manganese Steel Frog

A technology of comprehensive mechanics and high manganese steel, applied in the direction of casting molding equipment, furnace, heat treatment equipment, etc., can solve the problems such as not considering the rigid area of the hammer head, and achieve the improvement of fatigue life, mechanical properties and grain refinement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

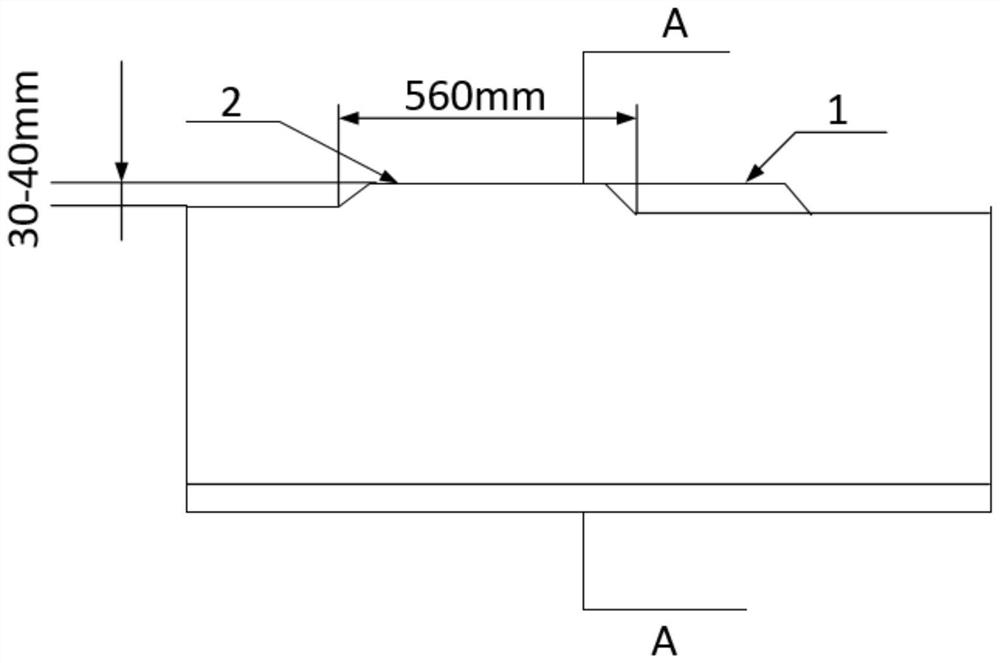

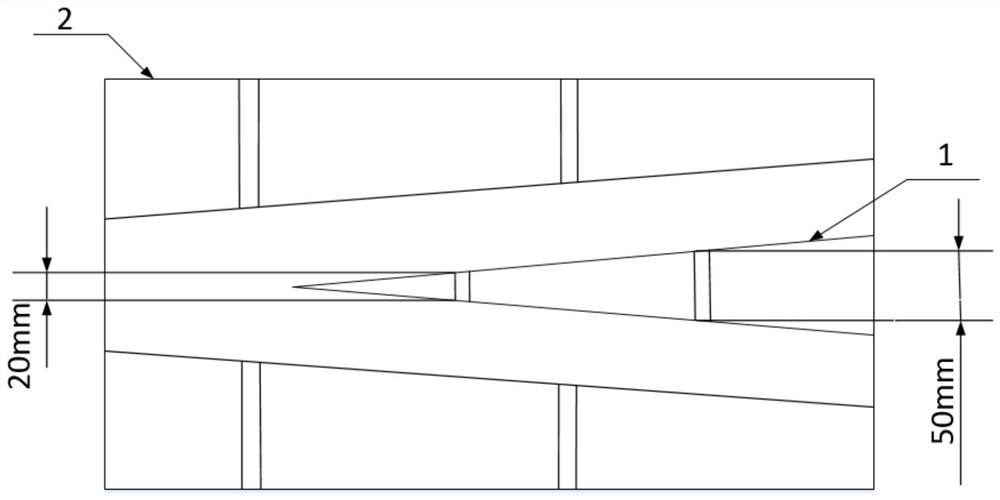

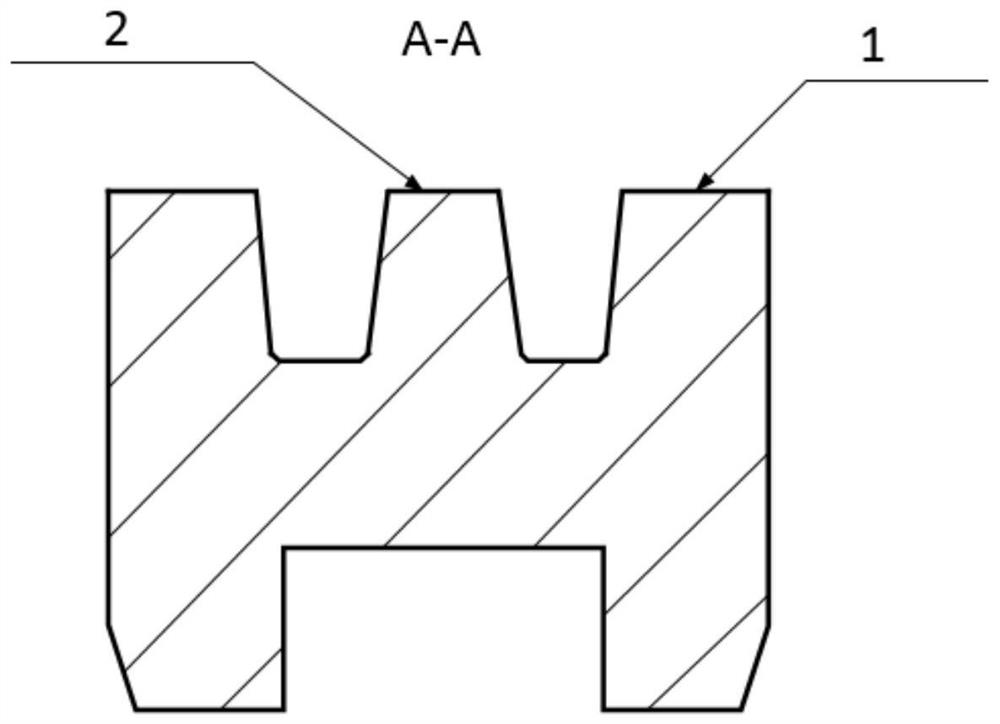

[0017] Firstly, when casting high manganese steel frogs, within the range of 20-50mm width of the core rail, the height of the core rail and the wing rail shall be raised as a whole. figure 1 shown. Put the high manganese steel frog into the forging furnace and fully heat it to 1150°C, then keep it warm for 6 hours to make the frog austenitized, and make the internal temperature of the frog reach 1150°C, then take it out of the forging furnace and place it in the next The upper mold and the lower mold need to be preheated to 300°C in advance; move the lower mold and frog to the right below the forging hammer, and start forging the frog. The forging hammer forges the frog to increase the surface at a speed of 10mm / s, and the forging time is 19s , the pressing height of the forging hammer is 22mm. At this time, the raised height of the frog becomes 18mm. The raised part of 18mm is cut off by mechanical cutting means, and then the processed high manganese steel frog is heated to ...

Embodiment 2

[0019] Firstly, when casting high manganese steel frogs, within the range of 20-50mm width of the core rail, the height of the core rail and the wing rail shall be raised as a whole. After being fully heated to 1200°C in the forging furnace, hold the temperature for 4 hours to austenitize the frog and make the internal temperature of the frog reach 1200°C. Take it out from the forging furnace and place it on the lower mold. The lower mold needs to be pre-prepared in advance. Heat to 300°C; move the lower die and frog to the right below the forging hammer, start forging the frog, the forging hammer forges the frog at a speed of 10mm / s to increase the surface, the forging time is 17s, and the pressing height of the forging hammer is 15mm At this time, the raised height of the frog becomes 15mm, and the raised part of 15mm is cut off by means of mechanical cutting, and then the treated high manganese steel frog is heated to 1150°C for 30 minutes for recrystallization and grain for...

Embodiment 3

[0021] Firstly, when casting high manganese steel frogs, within the range of 20-50mm width of the core rail, the height of the core rail and wing rail shall be raised as a whole. Put it into the forging furnace and heat it up to 1100°C, keep it warm for 6 hours to austenitize the frog, and make the internal temperature of the frog reach 1100°C, take it out from the forging furnace, and place it on the lower mold, which needs to be pre-prepared in advance. Heat to 300°C; move the lower mold and the frog to the right below the forging hammer, and start forging the frog. The forging hammer forges the frog at a speed of 10mm / s to increase the surface. The forging time is 18s, and the forging hammer presses down to a height of 18mm. At this time, the raised height of the frog becomes 17mm, and the raised part of 17mm is cut off by means of mechanical cutting, and then the treated high manganese steel frog is heated to 1160°C for 40 minutes for free diffusion and recrystallization a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com