Thick gauge q345r steel plate with excellent low-temperature impact toughness at core and manufacturing method

A low-temperature impact toughness, thick gauge technology, applied in the field of boiler and pressure vessel steel and its manufacturing, can solve the problems of reduced impact toughness, no production process plan, and less research on core performance, to ensure uniformity and excellent core performance. The effect of low temperature impact toughness and excellent low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

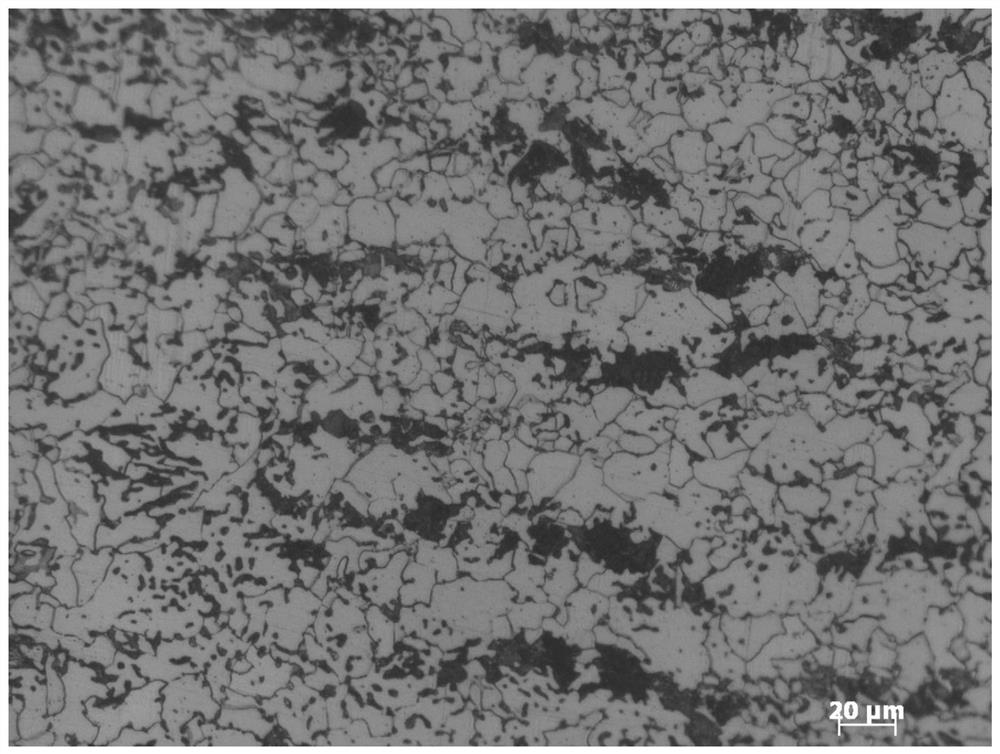

Image

Examples

Embodiment Construction

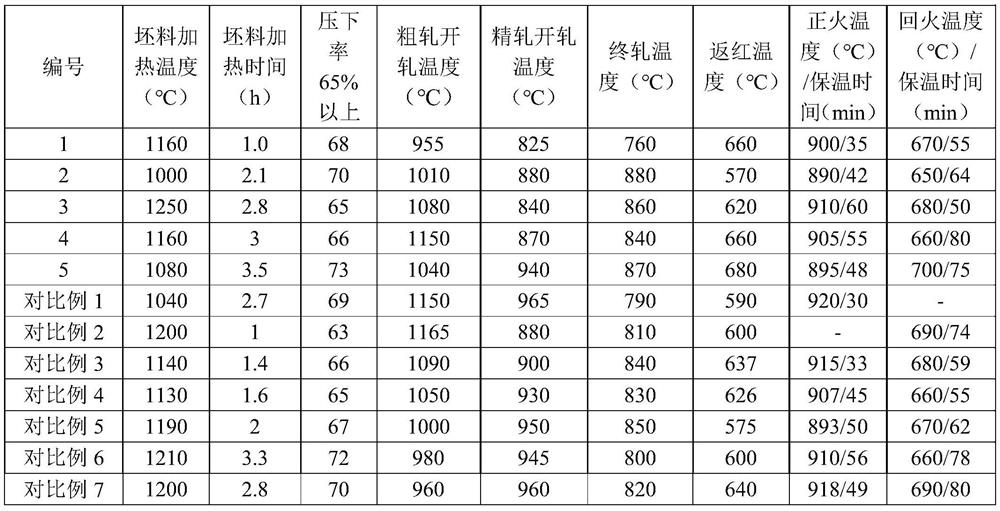

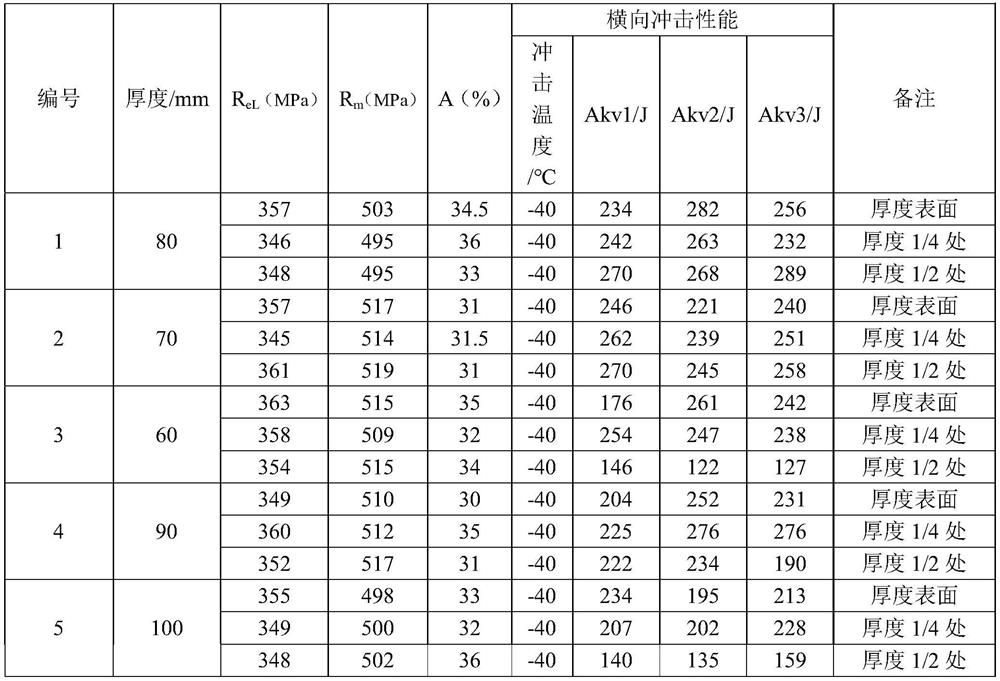

[0026] The following provides 5 sets of examples and 7 sets of comparative examples to describe in detail the properties of the thick gauge Q345R steel plate with excellent low-temperature impact toughness at the core of the present invention. The chemical composition of steel in each case is shown in Table 1:

[0027] The chemical composition of table 1 steel plate (remainder is Fe and impurity)

[0028] Numbering C mn Si P S Nb V Ni Ti Al 1 0.15 1.23 0.25 0.006 0.0008 0.026 0.05 0.35 0.01 0.01 2 0.165 1.32 0.2 0.008 0.001 0.04 0.02 0.1 0.02 0.05 3 0.155 1.2 0.35 0.005 0.0006 0.035 0.01 0.16 0.018 0.06 4 0.17 1.26 0.4 0.006 0.0009 0.018 0.04 0.24 0.016 0.01 5 0.158 1.27 0.35 0.007 0.0007 0.015 0.02 0.15 0.013 0.02 Comparative example 1 0.162 1.35 0.33 0.004 0.0005 0.033 0.03 0.28 0.014 0.04 Comparative example 2 0.167 1.3 0.29 0.006 0.0008 0.01 0.04 0.26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com