Movable cantilever hanging basket for steel box girder construction and construction method

A steel box girder and cantilever technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as labor-consuming and time-consuming, lower turnover rate and utilization rate of hanging baskets, and low construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

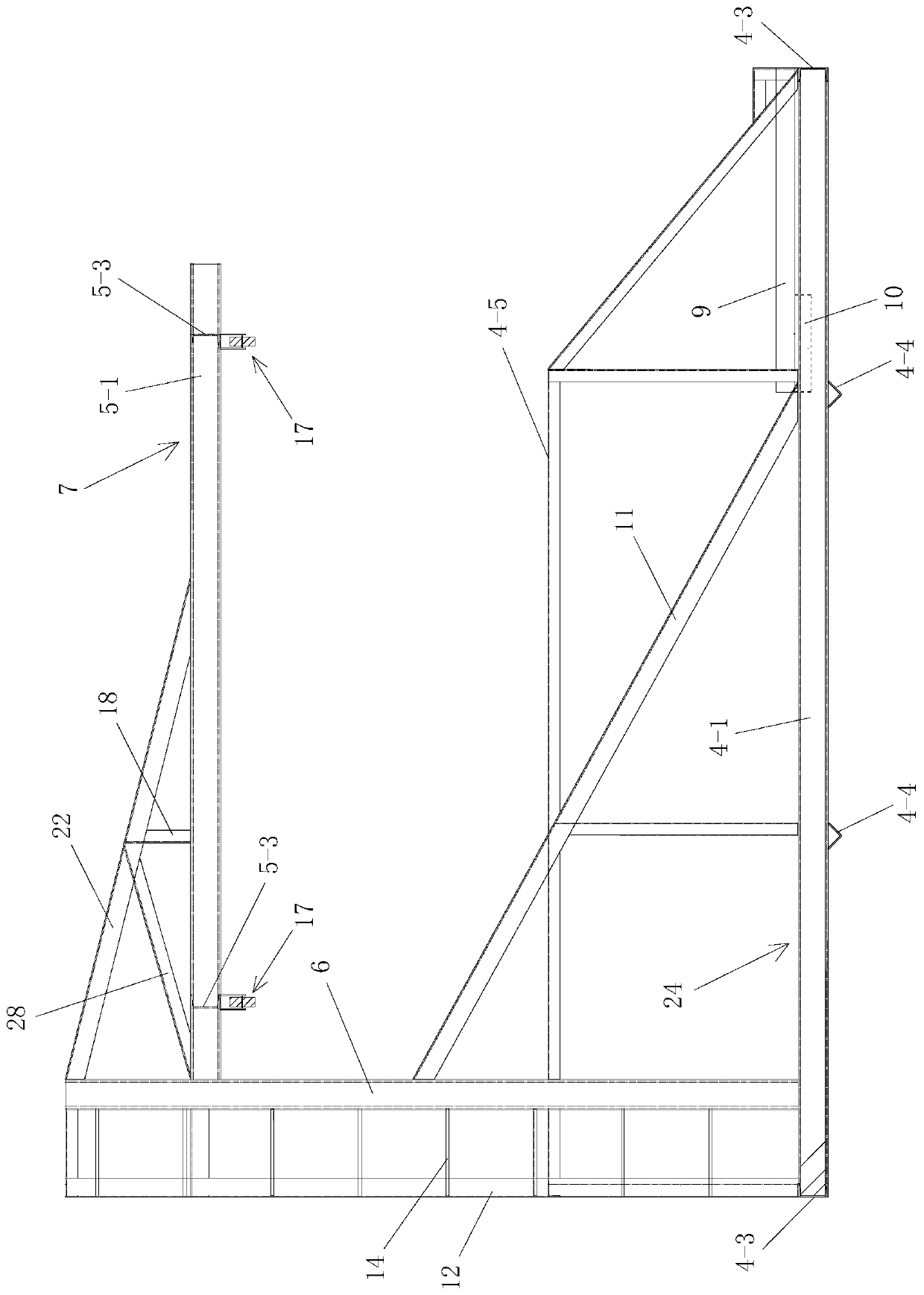

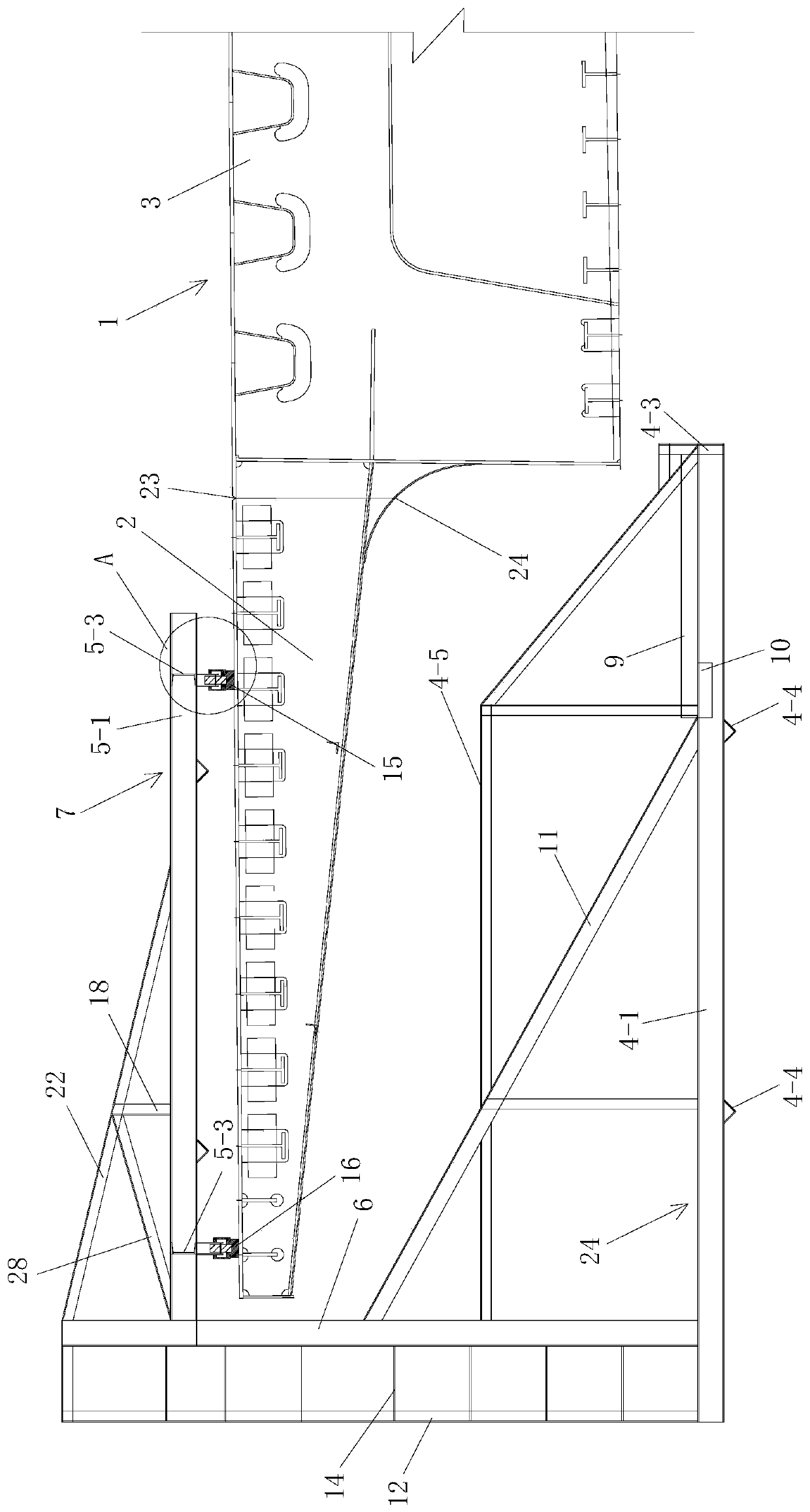

[0104] Such as figure 1 , figure 2 The shown movable cantilever hanging basket for steel box girder construction includes a hanging basket body that can translate on the steel box girder 1 under construction along the longitudinal length direction (ie, the longitudinal bridge direction), and is arranged on the hanging basket body. The hanging basket running device and the walking track for the hanging basket walking device to walk, the hanging basket walking device is installed on the walking track; the hanging basket body is arranged on a flange of the steel box girder 1 under construction On the plate 2, the flange plate 2 is the welded flange plate;

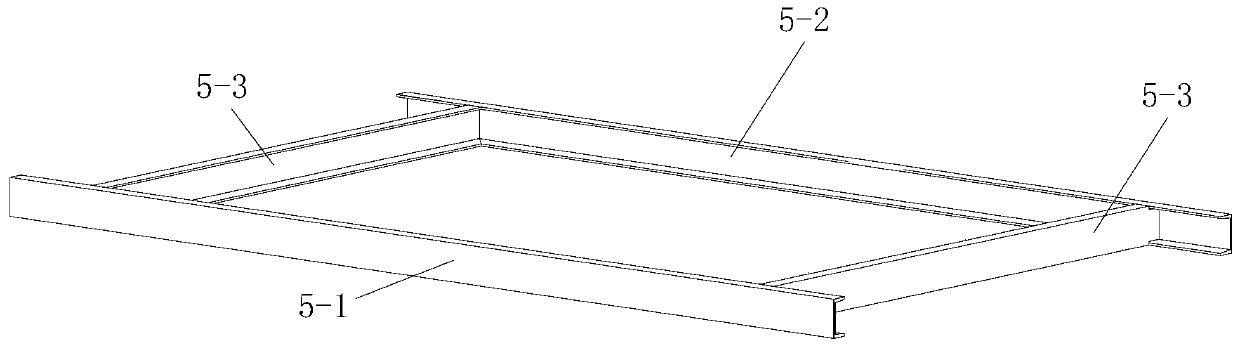

[0105] combine image 3 , Figure 4 , Figure 5 and Figure 9 , the hanging basket body includes a rear side support 7 and a vertical support frame arranged in front of the rear side support 7, and the rear side support 7 is arranged horizontally;

[0106] The vertical support frame is formed by connecting the lower fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com