Drill string disconnection and re-hookup device for non-riser dual-gradient drilling operation

A double-gradient and riser technology, which is applied in the direction of wellbore/well valve devices, drilling equipment, drill pipes, etc., can solve the problems of no drill string tie-back and channel re-opening, economic loss, unsatisfactory ball valve plugging effect, etc. problems, to achieve the effect of reducing the economic cost of mining and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to following description:

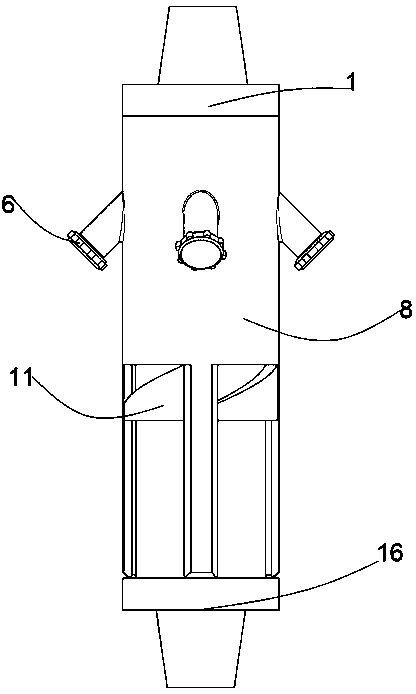

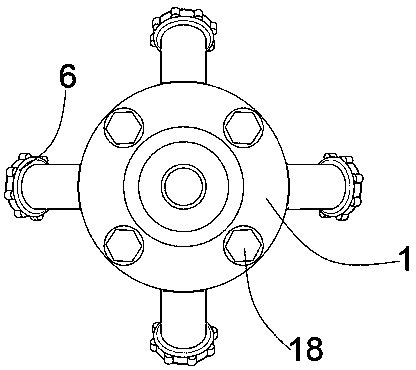

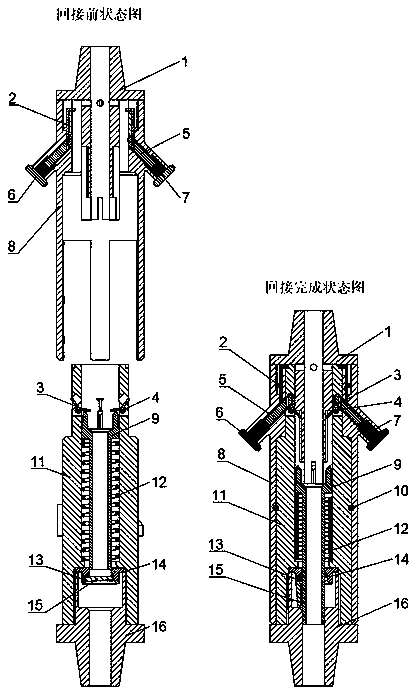

[0034] Such as Figure 1~11 As shown, a riserless dual-gradient drilling drill string uncoupling device, which includes an upper joint 1, a stop pin slider 2, a pin withdrawal rod 3, a rotating shaft 4, a shear pin 5, a spring sleeve 6, Push pin spring 7, outer shell 8, drive sliding sleeve 9, O-ring I10, inner shell 11, drive spring 12, rotating shaft 13, valve seat 14, valve disc 15, lower joint 16, torsion spring 17 and connecting screws 18; the upper joint 1 and the outer shell 8 are connected by connecting screws 18, the push pin spring 7 is loaded into the spring sleeve 6 and the shear pin 5 is screwed on the spring sleeve installation boss on the outer shell 8 to form a male part, and the back The pin rod part 3 is fixed in the installation rectangular hole 1103 of the inner housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com