High-temperature fluid quantitative discharging system and high-temperature fluid quantitative discharging method

A technology of high-temperature fluid and quantitative discharge, which is applied in fixed measuring chambers and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

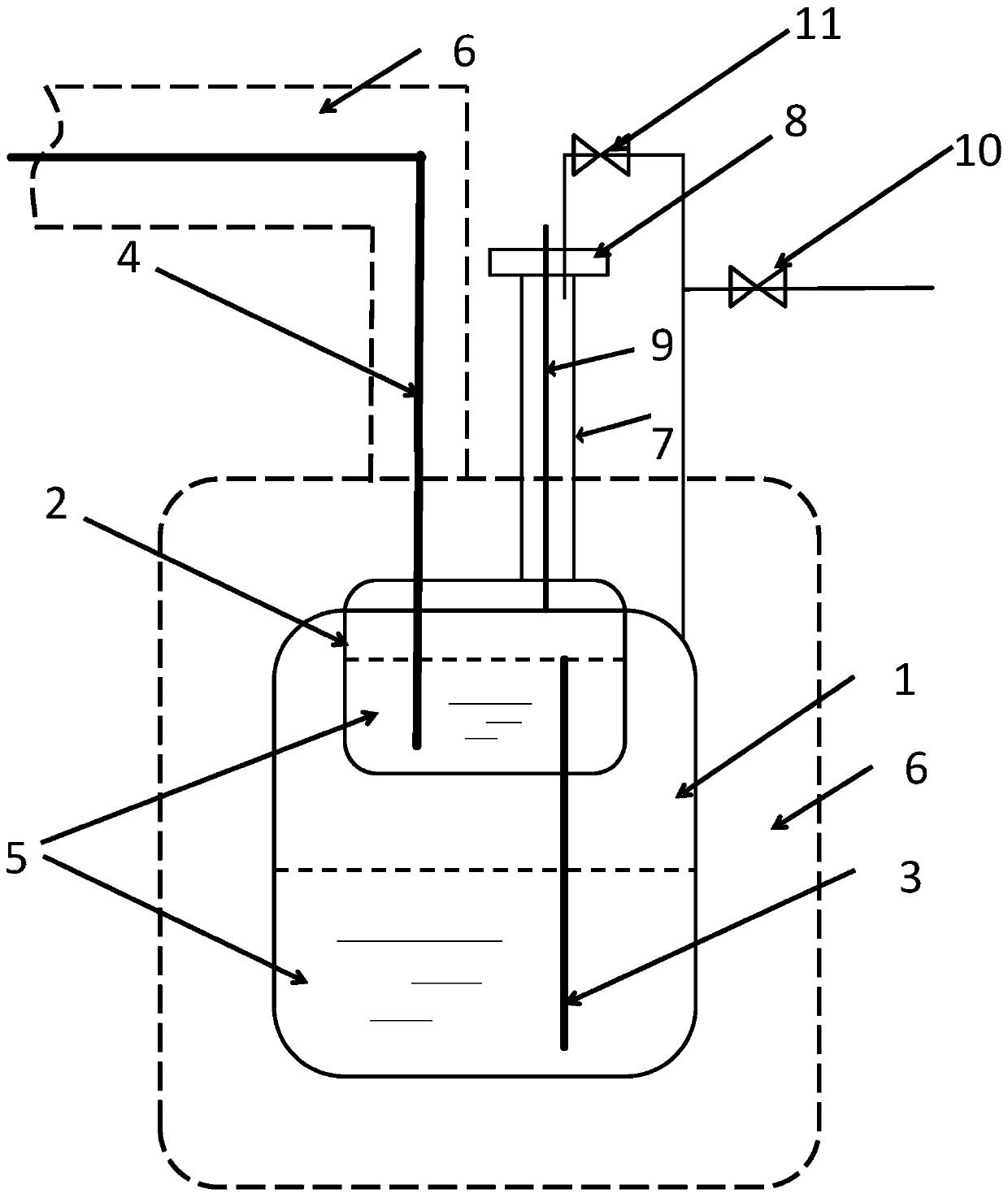

[0060] The high-temperature fluid quantitative discharge system provided in this embodiment is as follows: figure 1 shown. It includes a first container 1, a second container 2 and a gas system, the first container 1 and the second container 2 are airtight containers, the second container 2 is set above the first container 1, and the second container 2 The inner diameter is smaller than the inner diameter of the first container 1; the bottom surface of the second container 2 is vertically sealed with a first conduit 3, the top of the first conduit 3 extends into the middle and upper part of the inner cavity of the second container 2, and the bottom end extends into the inner cavity of the second container 2. The bottom of the inner cavity of the first container 1; The top surface of the second container 2 is also vertically sealed with a second conduit 4, and the bottom end of the second conduit 4 stretches into the bottom of the inner cavity of the second container 2; The sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com