High-temperature ductility cracking quasi-in-situ test method of nickel-based alloy welding material

A nickel-based alloy and welding material technology, which is applied in the field of high-temperature loss crack testing of nickel-based alloy welding materials, can solve problems such as inability to distinguish high-temperature loss cracks and liquefaction cracks, inability to accurately obtain critical strain, and inaccurate evaluation. To achieve the effect of true and reliable test results, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A quasi-in-situ evaluation method for high-temperature loss and cracking of nickel-based alloy welding materials, the method comprising the following steps:

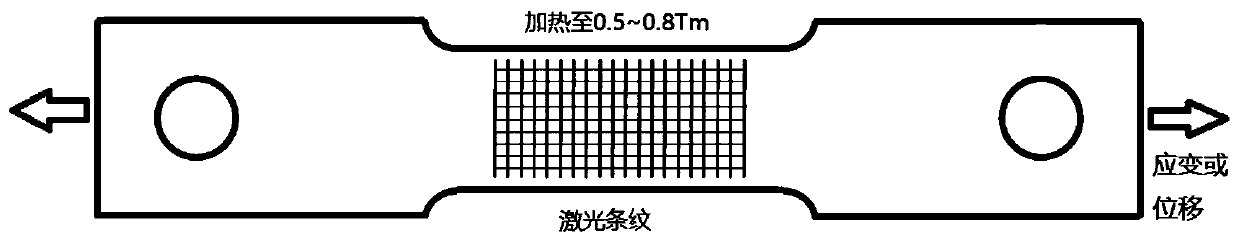

[0032] (1) Take samples from the surfacing layer of nickel-based alloy welding materials, process tensile samples, the sample size is 70×15×3mm, the surface of the sample is pre-ground to 2000 mesh sandpaper, and then polished and electrolytically corroded to expose the microstructure appearance, and no obvious scratches.

[0033] (2) Use a laser marking machine to prepare several straight stripes in the central area of the tensile sample surface within 20mm along the width direction and length direction, the stripe line width and depth are 1-5μm, and the stripe spacing is 0.2-1mm.

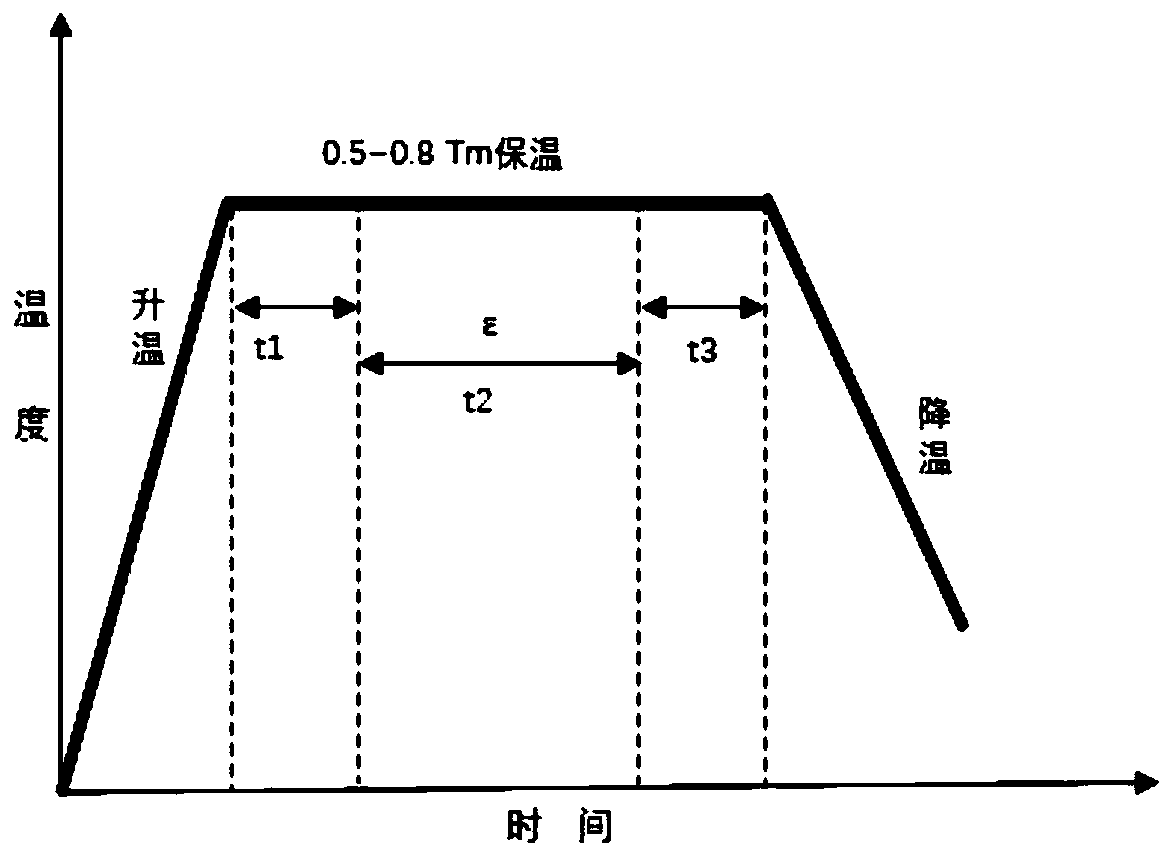

[0034] (3) Load the sample on the Gleeble thermal simulation testing machine and vacuumize it. Rapidly heat the sample to 0.5-0.8Tm (Tm is the melting point), keep it warm for 30s, then apply a displacement at a certain rate, and k...

Embodiment 2

[0038] The method for testing and evaluating the high-temperature loss cracking of nickel-based alloy materials in this embodiment mainly includes the following steps:

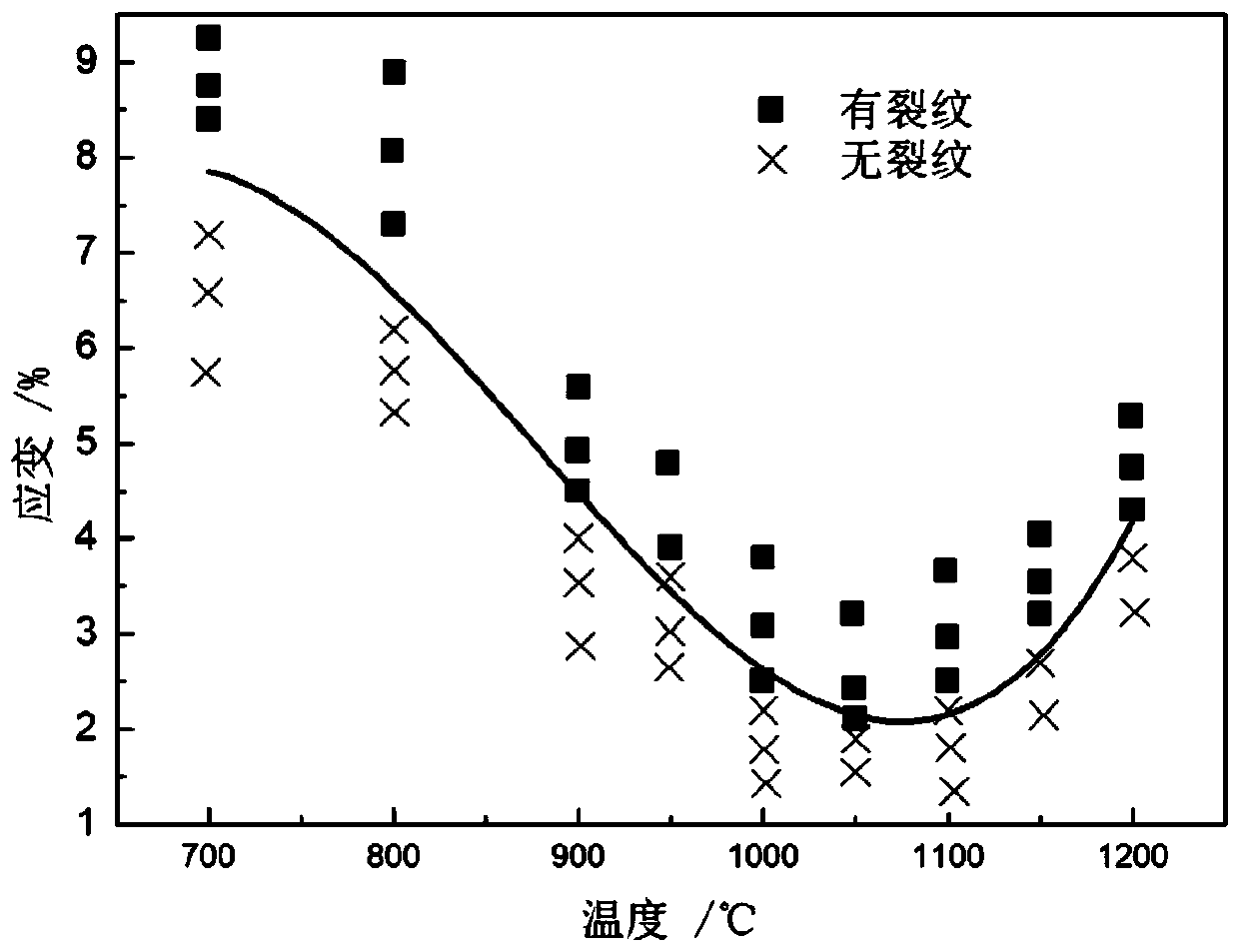

[0039] (1) Taking the nickel-based alloy FM52 surfacing material as an example, 7 peak temperatures are selected, and 6 to 8 tensile specimens are processed at each temperature. The schematic diagram of the tensile specimens is shown in figure 1 . Among them, the length of the tensile sample is 70 mm, the width is 15 mm, and the thickness is 3 mm.

[0040] (2) Mechanically grind the surface of all samples to a fineness of 2000 mesh sandpaper. During this process, the final thickness of the sample is reduced to about 2.8mm, and then the surface is polished.

[0041] (3) Use a laser marking machine to prepare parallel stripes along the width and length directions in the 20 mm area of the center of the sample surface. The depth and width of the stripes in the width direction are about 5 μm, the edges are smoot...

Embodiment 3

[0049] A kind of quasi-in-situ testing method of high-temperature loss-delay cracking of nickel-based alloy welding materials, the method comprising the following steps:

[0050] 1) Perform surface pretreatment on the tensile sample of nickel-based alloy welding material. The surface pretreatment process is: use 2000 mesh sandpaper to pre-grind the surface of the tensile sample, then polish to W0.5, and then electrolytically corrode to Can present microstructure;

[0051] 2) A laser is used to prepare multiple horizontal stripes and multiple longitudinal stripes in the central area of the tensile sample. The horizontal stripes are parallel to the width direction of the tensile sample, and the longitudinal stripes are parallel to the length direction of the tensile sample; the length of the horizontal stripes is 8-12mm, width and depth are 1-5μm; the length of the longitudinal stripes is 18-22mm, width and depth are 1-5μm; two adjacent horizontal stripes or between two adjace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com