Special malt quality evaluation method

A technology for special malt and quality evaluation, applied in measuring devices, testing food, instruments, etc., can solve problems such as inconsistent product quality control standards, inconsistent product classification standards, and inconvenient use by brewers, and achieve accurate evaluation of flavor characteristics, The effect of solving the inconsistency of classification standards and filling the gaps in the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The quality evaluation method of embodiment 1 special malt I (sample 1#)

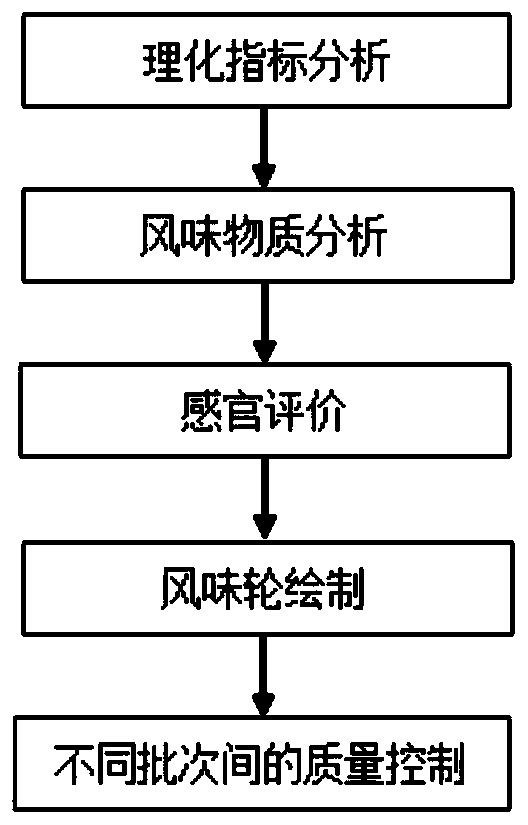

[0038] Including the following steps:

[0039] S1. Analysis of physical and chemical indicators.

[0040] Analyze the physical and chemical indicators of the quality of sample 1#, which mainly involves chroma, which is consistent with that in "Beer Malt". After analysis, the chromaticity of sample 1# is 290EBC.

[0041] Table 1 Typical specialty malt color ranges are:

[0042]

[0043]

[0044] It can be seen from Table 1 that the chromaticity of sample 1# is in the range of 280-320EBC, and proceed to the next step of analysis of flavor substances.

[0045] S2. Analysis of flavor substances.

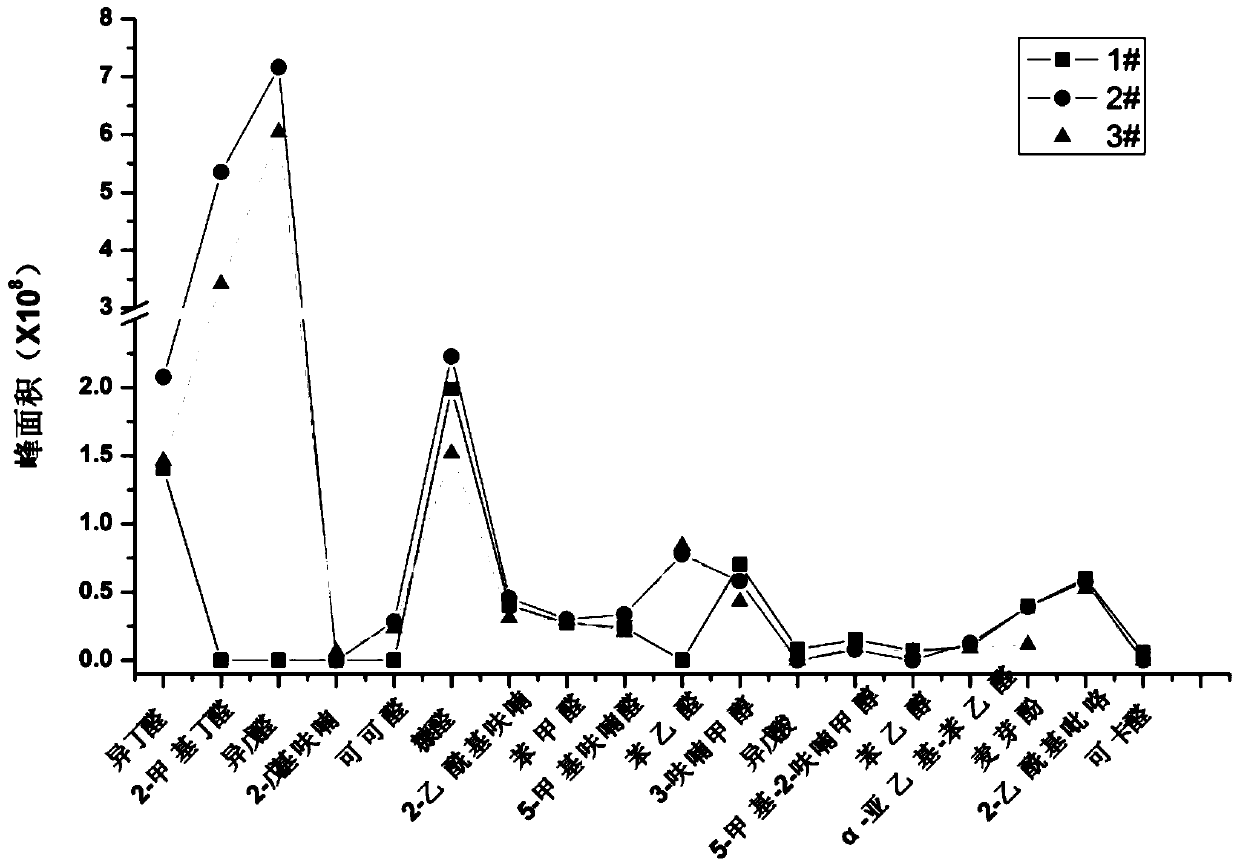

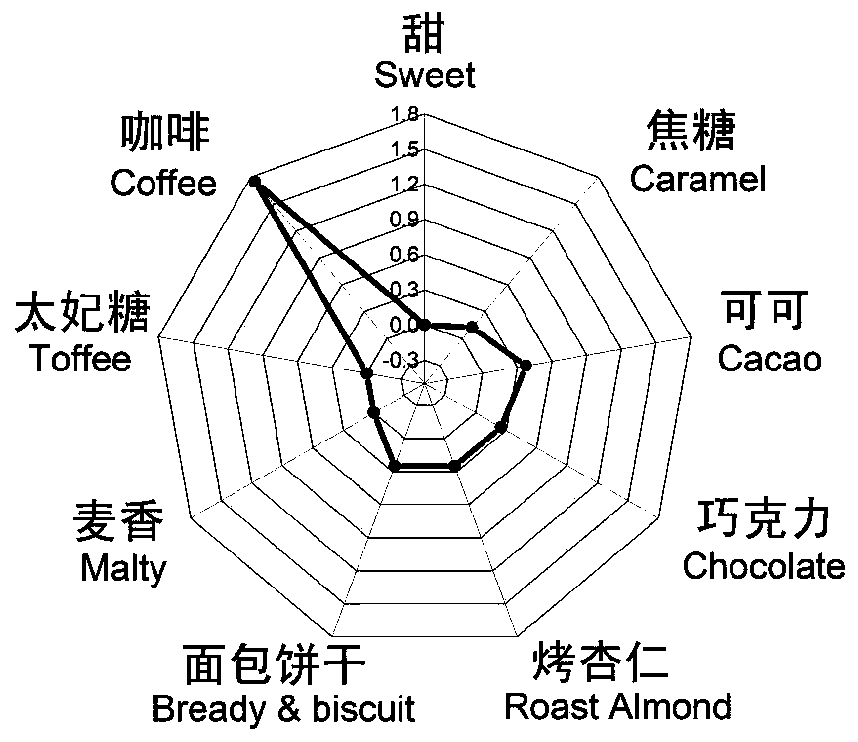

[0046] First, headspace-solid-phase microextraction-gas chromatography-mass spectrometry was used to detect the types and contents of flavor substances in various special malts, as shown in Table 2, and the characteristics and rules of flavor substances of various special malts were summarized.

...

Embodiment 2

[0071] The quality evaluation method of embodiment 2 special malt II (sample 2#)

[0072] Including the following steps:

[0073] S1. Analysis of physical and chemical indicators.

[0074] The analysis method is the same as in Example 1. After analysis, the chromaticity of sample 2# is 135EBC. It can be seen from Table 1 that the chroma of sample 1# is within the range of light-colored crystalline malt, and the next step of analysis of flavor substances is continued.

[0075] S2. Analysis of flavor substances.

[0076] Analytical method is with embodiment 1, through testing result such as figure 2 As shown, the flavor substances contained in sample 2# are aldehydes such as isobutyraldehyde, isovaleraldehyde, 2-methylbutyraldehyde, n-hexanal, benzaldehyde, phenylacetaldehyde, and 2-acetylfuran, 5-formaldehyde It contains multiple oxygen-containing heterocyclic compounds such as furyl aldehyde, maltol and pineapple ketone, and does not contain nitrogen-containing heterocycl...

Embodiment 3

[0083] The quality evaluation method of embodiment 3 special malt III (sample 3#)

[0084] Including the following steps:

[0085] S1. Analysis of physical and chemical indicators.

[0086] The analysis method is the same as in Example 1. After analysis, the chromaticity of sample 3# is 140EBC. It can be seen from Table 1 that the chromaticity of sample 3# is in the range of 130-160EBC, and proceed to the next step of analysis of flavor substances.

[0087] S2. Analysis of flavor substances.

[0088] Analytical method is with embodiment 1, through testing result such as figure 2 As shown, the flavor substances contained in sample 3# are isobutyraldehyde, 2-methylbutyraldehyde, isovaleraldehyde, 2-pentylfuran, cocoal, furfural, 2-acetylfuran, benzaldehyde, 5-methyl furan aldehyde, phenylacetaldehyde, 3-furan methanol, 5-methyl-2-furan methanol, phenylethanol, α-ethylene-phenylacetaldehyde, maltol and 2-acetylpyrrole, etc., it can be seen that the sample The types of volat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com