Fan-type gas circulation high repetition frequency Raman cell

A gas circulation and high repetition rate technology, applied in the laser field, can solve the problems of reducing beam power density and Raman gain, Stokes beam quality deterioration, and Raman conversion efficiency decline, etc., to achieve high pump energy, The effect of not being easily damaged and reducing the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

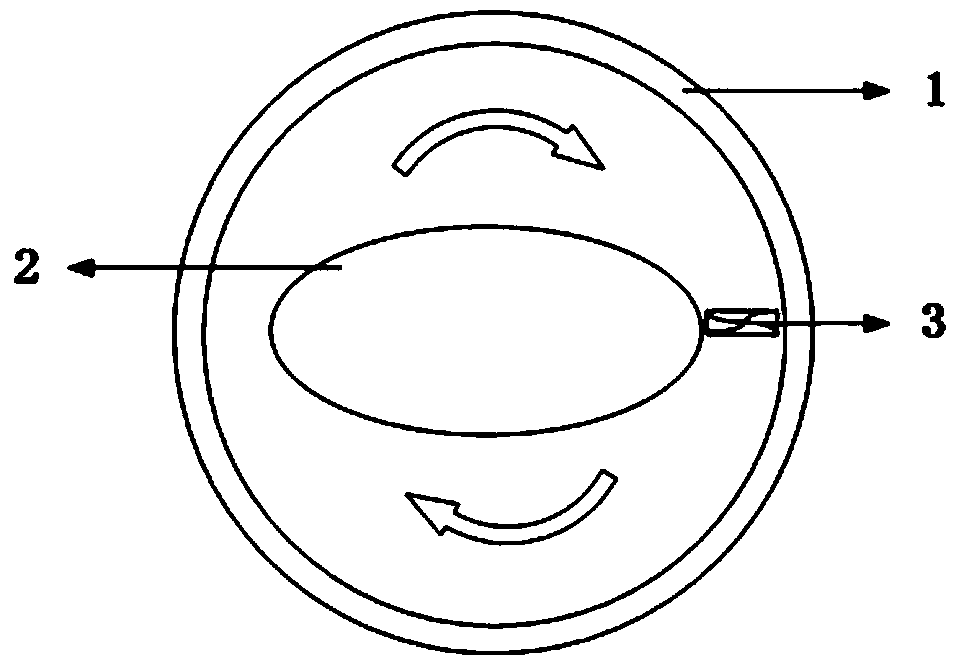

[0034] First, a Raman cell wall with a circular cross section and a filler with an elliptical cross section are used. Place the three-dimensional filler with an elliptical cross-section in the Raman cell, and the position is coaxial with the Raman cell. Adjust the filler or the Raman cell appropriately so that the specifications and sizes of the formed narrow channels are the same, and the formed wide channels The specifications and sizes are the same, and the maximum spacing length between the filler and the Raman cell wall is twice the minimum spacing length. One of the narrow passages is equipped with a row of electric fans, and the other narrow passage is used as a light passage.

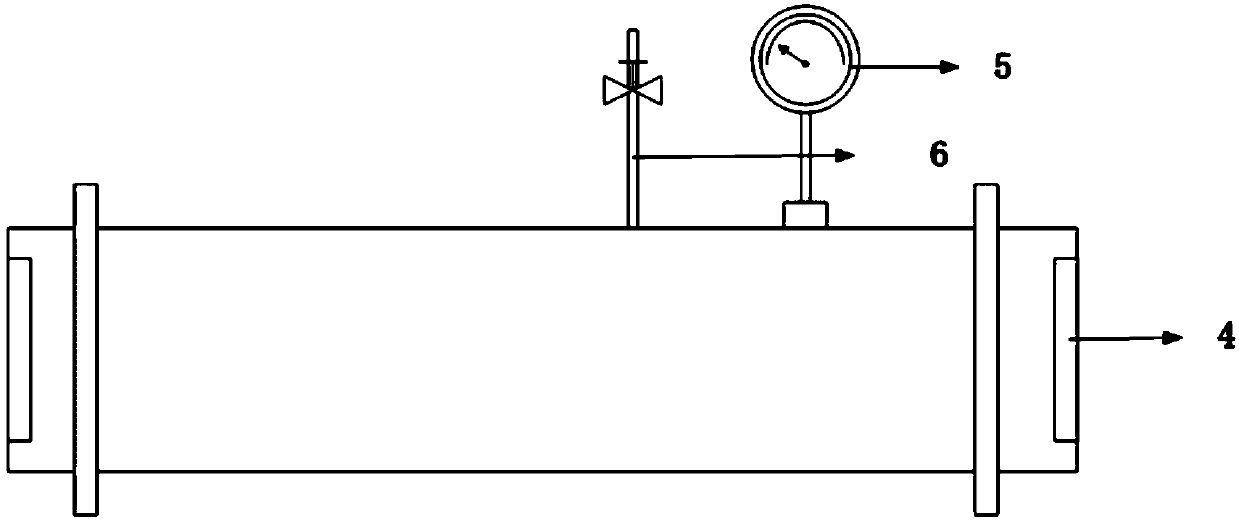

[0035]Fill the Raman cell with sufficient gas medium (the gas should be replaced several times for the first time to ensure the purity of the gas in the Raman cell), adjust the ventilation valve to the required air pressure, and then run the fan group in the Raman cell to stabilize the internal ...

Embodiment 2

[0037] First, a Raman cell wall with a circular cross-section and a filler with an equilateral triangle cross-section are used. Place the three-dimensional filler with an equilateral triangle cross section in the Raman cell, the position is coaxial with the Raman cell, and adjust the filler or the Raman cell appropriately so that the specifications and sizes of the formed narrow channels are the same, and the width of each formed channel is the same. The channel dimensions are the same, and the maximum gap length between the filler and the Raman cell wall is three times the minimum gap length. One of the narrow passages is equipped with a row of electric fan groups, and one of the remaining narrow passages is selected as a light passage.

[0038] Fill the Raman cell with sufficient gas medium (the gas should be replaced several times for the first time to ensure the purity of the gas in the Raman cell), adjust the ventilation valve to the required air pressure, and then run th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com