Three-level six-phase permanent magnet synchronous motor dual-mode operation control system and control method

A permanent magnet synchronous motor, operation control technology, applied in the control system, motor control, AC motor control, etc., can solve the problems of high harmonics, limited power level of three-level inverter, large motor torque ripple, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

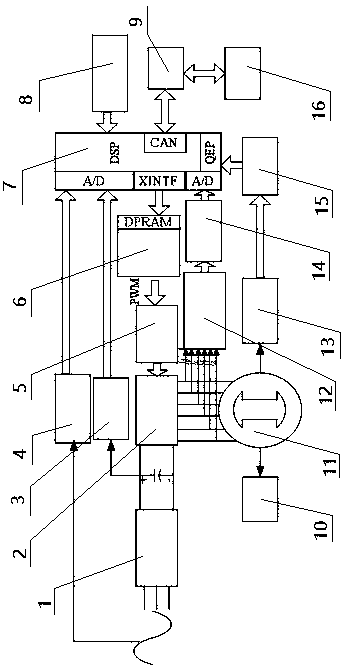

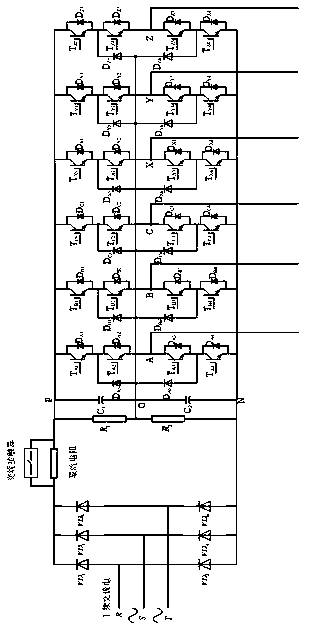

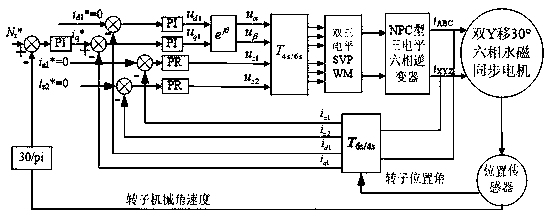

[0068] A three-level six-phase permanent magnet synchronous motor dual-mode operation control system, which consists of: a control circuit, the PWM signal output by the control circuit is electrically connected to the drive circuit 5, and the drive circuit is connected to the six-phase inverter 2 are electrically connected, the six-phase inverter is electrically connected to the three-phase uncontrolled rectification circuit 1 of the frequency converter, the front end of the three-phase uncontrolled rectification circuit of the frequency converter is connected in parallel with a phase loss detection circuit 4, and the The rear end of the three-phase uncontrolled rectification circuit of the frequency converter is electrically connected to the bus voltage detection circuit 3, and the phase loss detection circuit and the bus voltage detection circuit are electrically connected to the A / D interface of the controller. The six-phase inverter mentioned above is input to the A / D inter...

Embodiment 2

[0070] According to the three-level six-phase permanent magnet synchronous motor dual-mode operation control system described in embodiment 1, the described controller is composed of DSP, part number: 7 and FPGA, part number: 6, and the described DSP and the described FPGA electrical connection.

Embodiment 3

[0072] According to the dual-mode operation control system of the three-level six-phase permanent magnet synchronous motor described in Embodiment 1 or 2, the DSP is communicatively connected with the upper computer 16 through the CAN communication circuit 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com