System for machining workpieces

A technology for processing workpieces and workpieces, applied in the general control system, control/regulation system, comprehensive factory control, etc., to achieve the effect of increasing the scope of use, improving efficiency, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, preferred embodiments of the present invention will be described in detail with reference to the drawings. The further variants mentioned in this regard of specific individual features can each be combined with one another in order to form new embodiments.

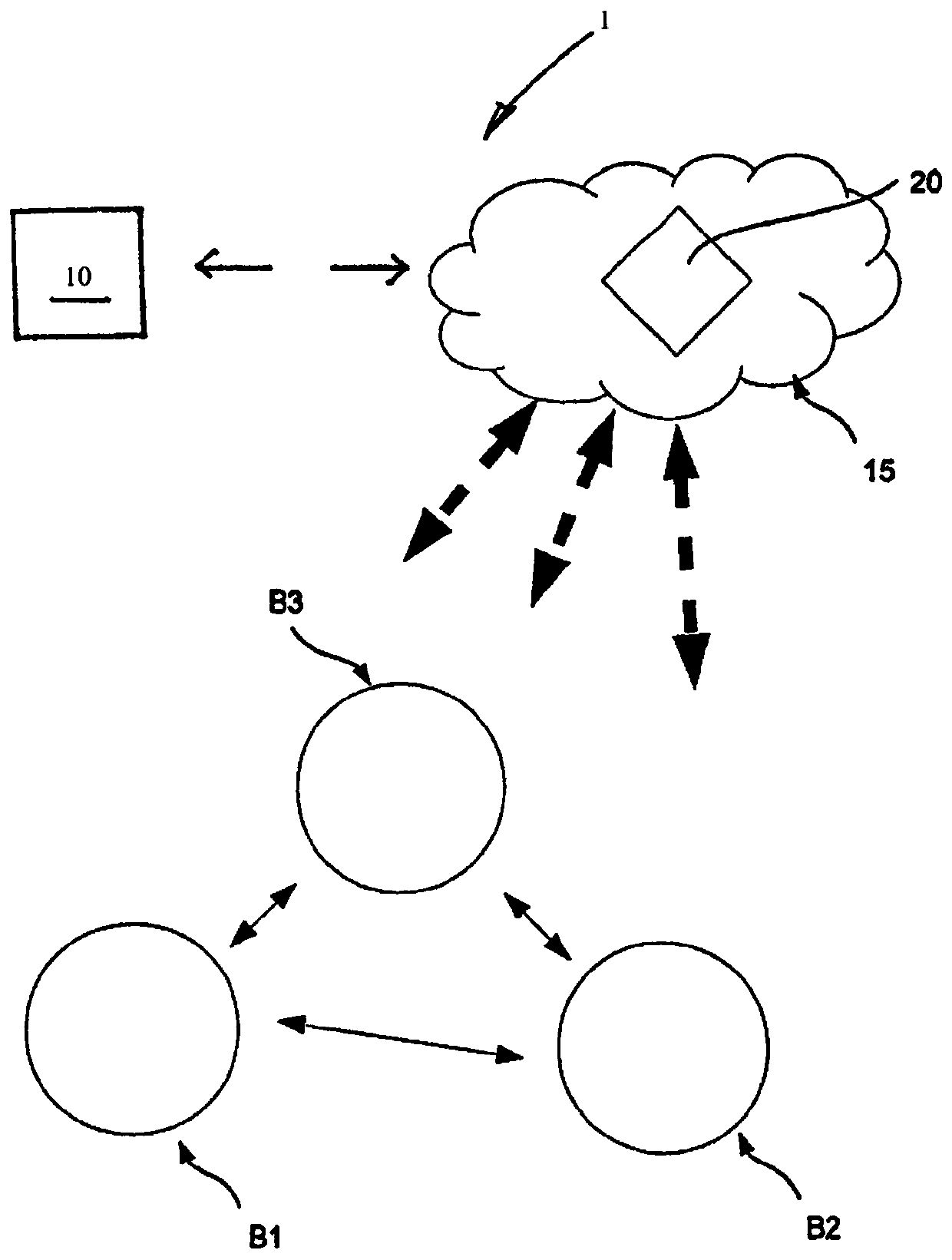

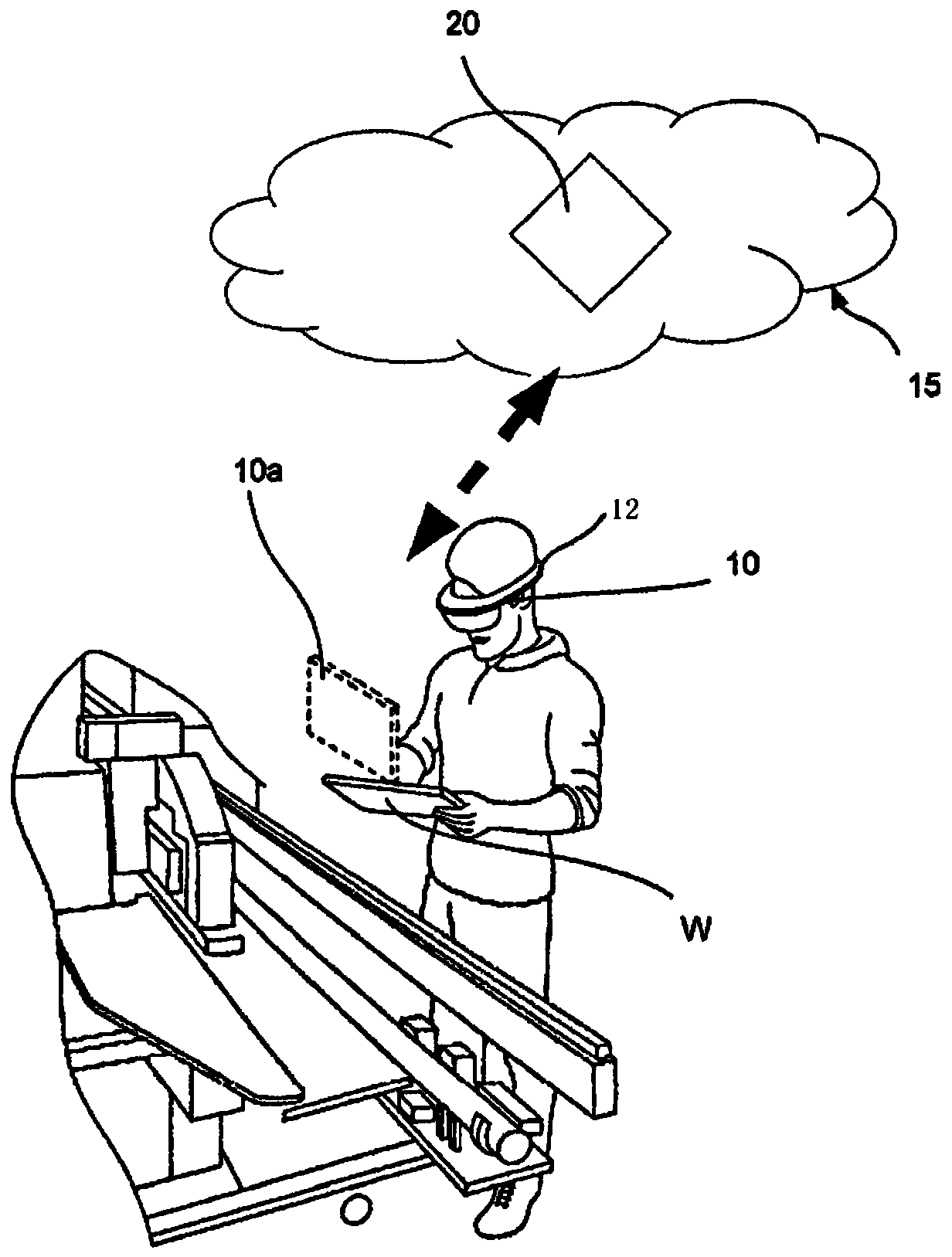

[0025] A system 1 for machining workpieces according to one embodiment of the invention is figure 1 shown schematically. The system 1 is used for processing workpieces which at least partially consist of wood, wood-based panels, plastics or the like, such as solid wood boards, laminated boards, particle boards, MDF boards, HDF boards or the like. Such workpieces are preferably used in the field of the furniture and component industry. Purely by way of example, these are kitchen countertops, shelf panels, floors, doors and the like.

[0026] In the present embodiment, the system 1 comprises purely by way of example three machining devices B1 , B2 and B3 , which are respectively used to perform workpiece mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com