Chlorination process of 2,4-dinitroaniline

A technology of dinitroaniline and process, which is applied in the field of chlorination process of 2,4-dinitroaniline, can solve the problems of inability to control the amount of feed well, troublesome operation of workers, etc., so as to reduce the difficulty of operation of workers, Effects of reducing residue and increasing reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A chlorination process of 2,4-dinitroaniline, the specific steps are: adding lignosulfonate to 2,4-dinitroaniline, then putting the mixture into water to suspend it in water; Add hydrochloric acid into the tank, then add 2,4-dinitroaniline suspension and sodium chlorate into the mixing tank at the same time, react to drive out excess chlorine, add sodium bisulfate to the reactant to decompose residual chlorine, filter, and wash to medium The product was obtained by drying; the hydrochloric acid concentration was 32%; the 2,4-dinitroaniline suspension and sodium chlorate were added to the mixing tank and stirred for 30 minutes, and then the excess chlorine was driven out through 30 minutes; the 2,4-Dinitroaniline suspension and sodium chlorate are added and stirred while the temperature of hydrochloric acid in the mixing tank is 25°C; the ratio of 2,4-dinitroaniline, lignosulfonate and water is 366:1: 440.

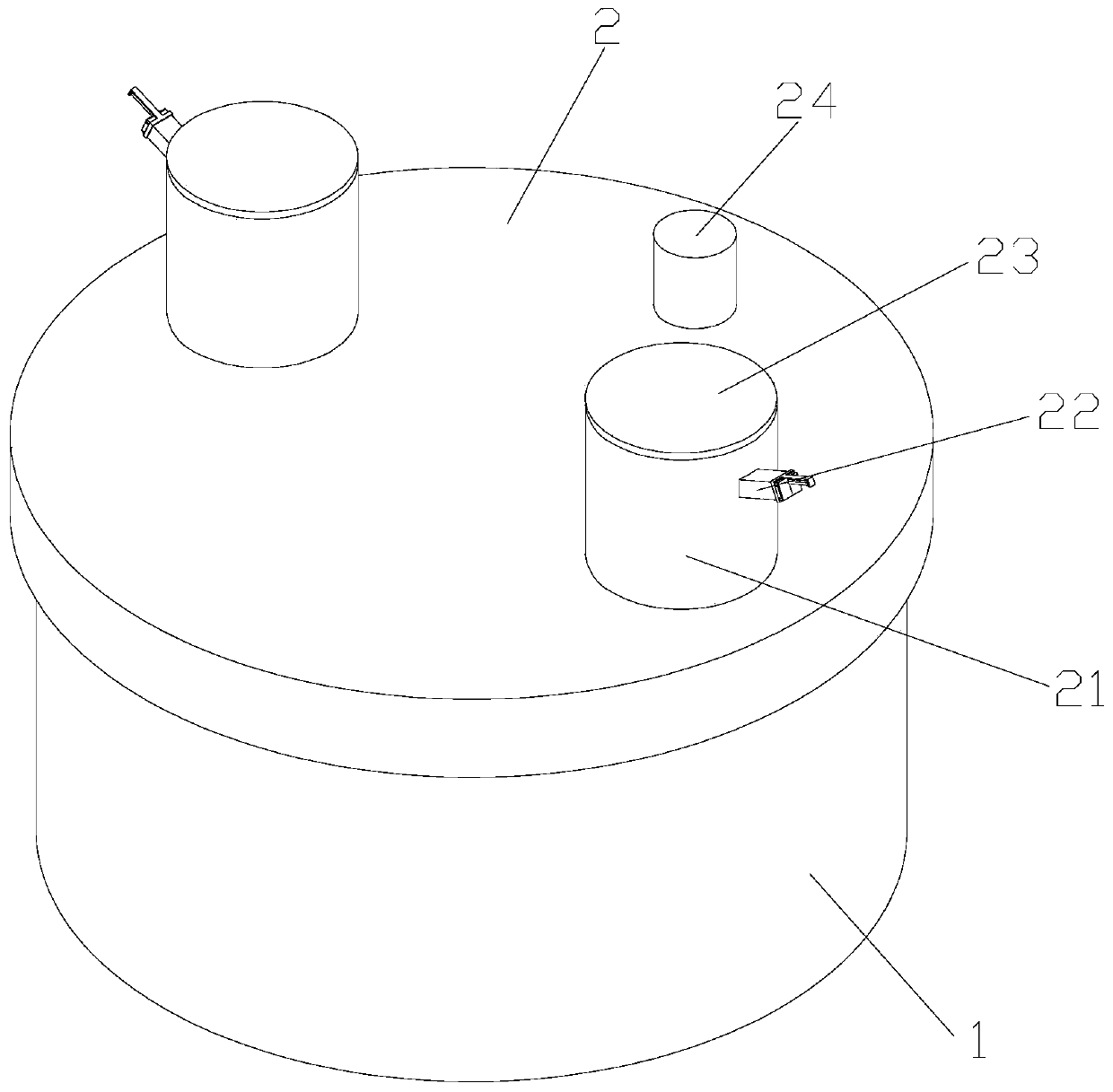

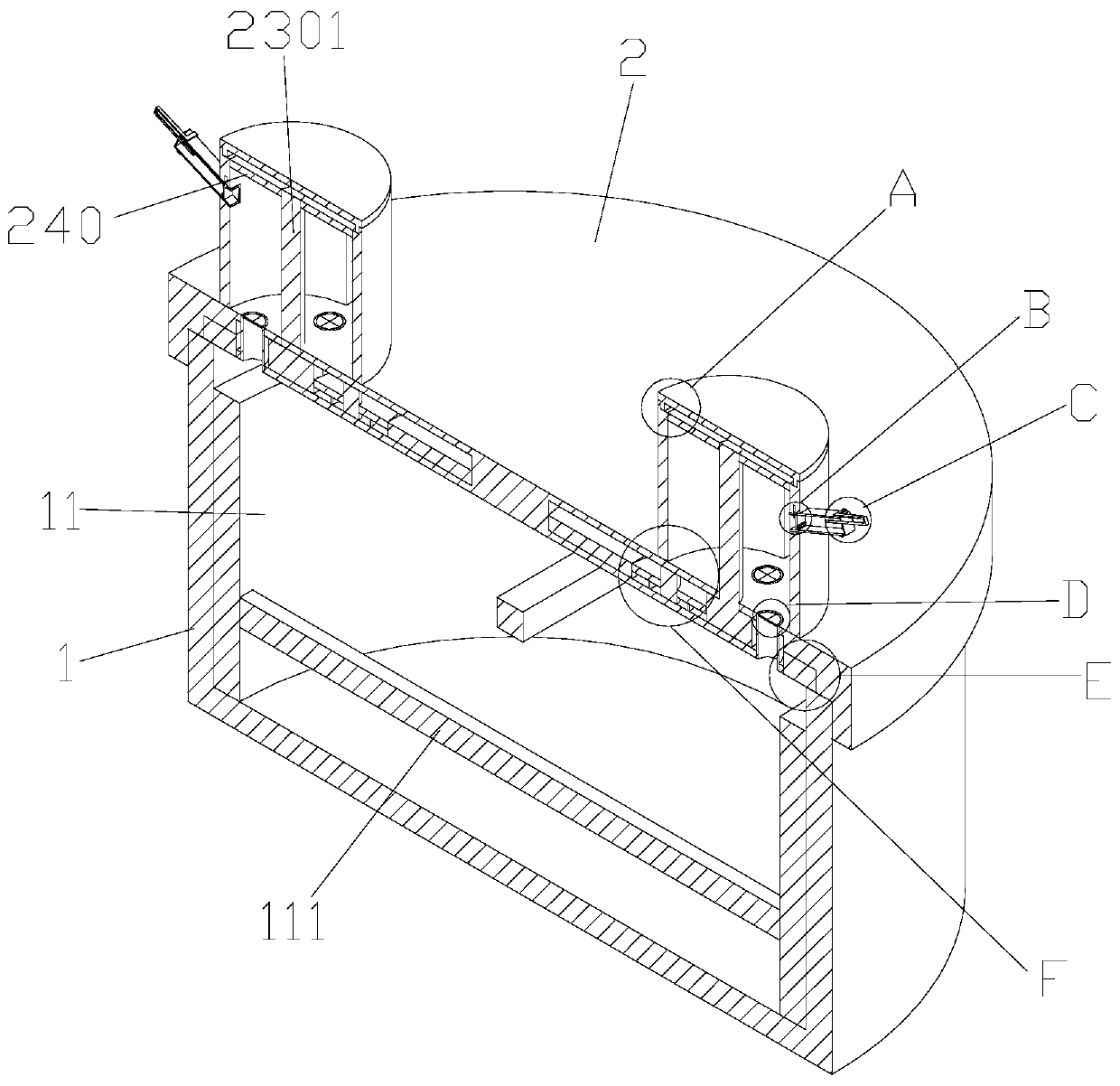

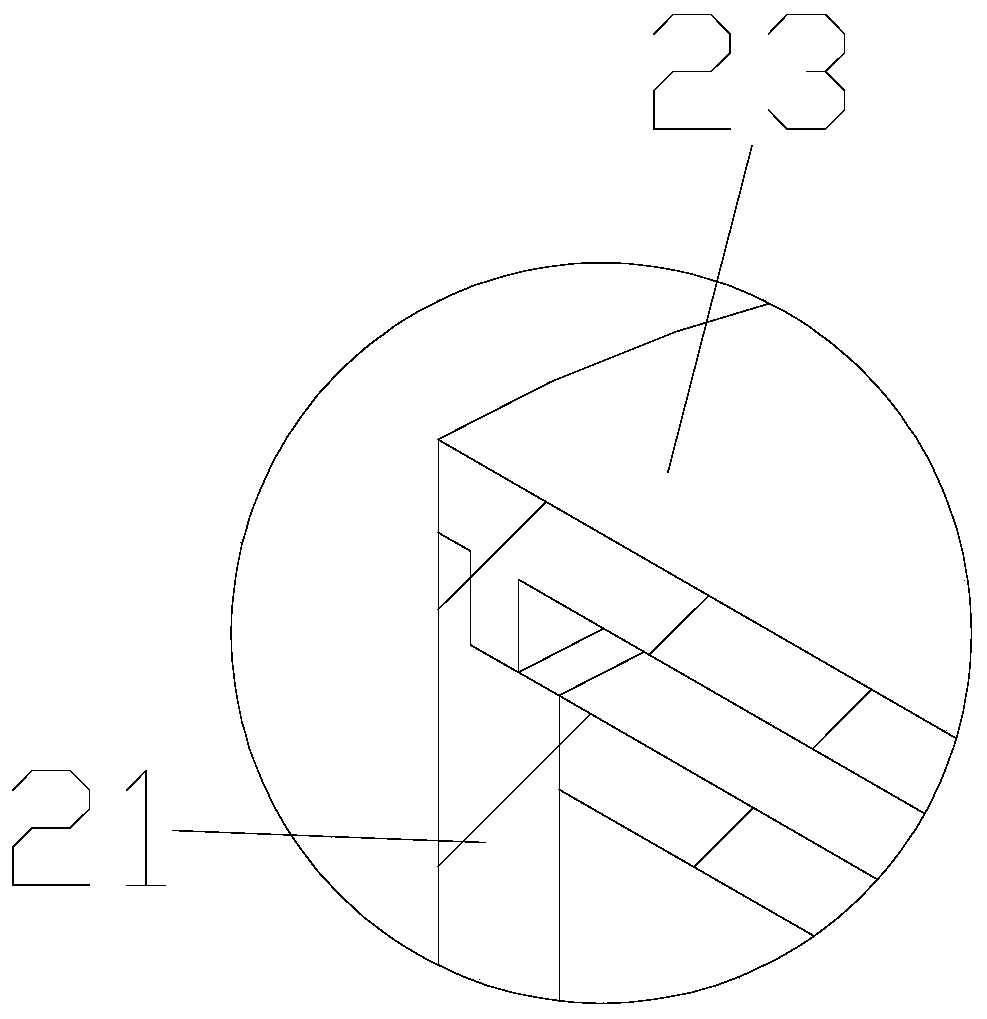

[0028] Such as Figure 1-12As shown, the top of the mixing ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com