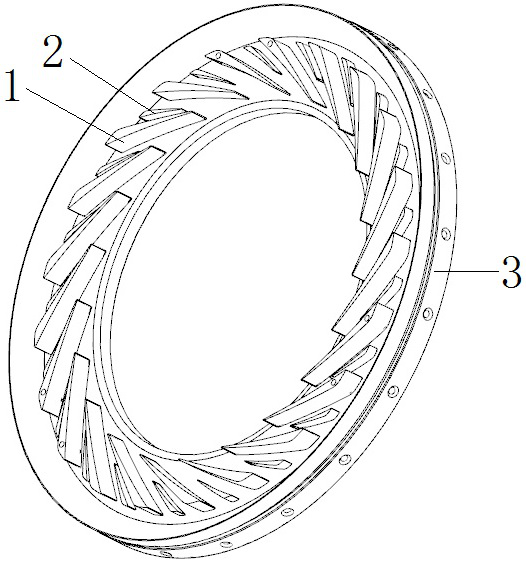

A wedge-shaped diffuser with half-height small vanes

A technology of small blades and diffusers, applied in the direction of machines/engines, pumping devices for elastic fluids, non-variable pumps, etc., can solve the development of aggravated diffuser airflow separation, diffuser Reduced diffusion capacity, reduced working range, etc., to achieve good use and promotion effects, prevent surge failures, and increase working margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Aiming at the existing miniature turbojet engine with a thrust of 100kg, the invention is used to improve the design of the off-compressor in the miniature turbojet engine.

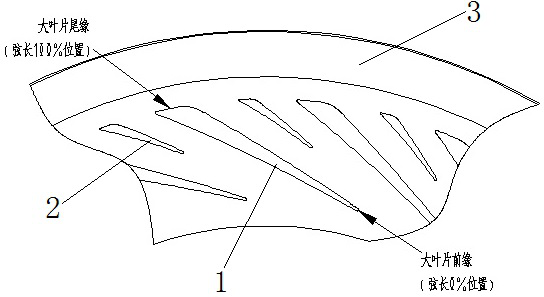

[0039] The wedge-shaped diffuser is parameterized, and the airfoil shape is a straight blade with a mid-arc line and a thickness distribution. Among them, the arc angle distribution and blade thickness distribution curves are described by Bezier curves. The large blade is not modified, and the small blade is designed according to the extracted mid-arc and thickness distribution of the large blade.

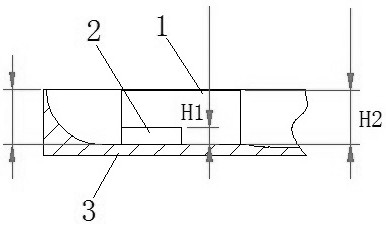

[0040] The starting position of the leaflet is determined by the position where the channel separation of the original leaf occurs. After optimal selection, the starting position of the small blade is located at 60% of the chord length of the large blade. The height of the small blade is determined according to the percentage of the low-velocity zone at the outlet rim of the original blade passage to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com