Automobile anti-pinch strip with high sensitivity

A sensitivity and automotive technology, applied in vehicle parts, engine seals, wing leaf control mechanisms, etc., can solve the problems of narrow anti-pinch trigger angle range, inability to achieve sensitive anti-pinch, poor sealing of automobiles, etc., and achieve simplified cross-section structure And the effect of production process, simple structure, strong rigidity and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

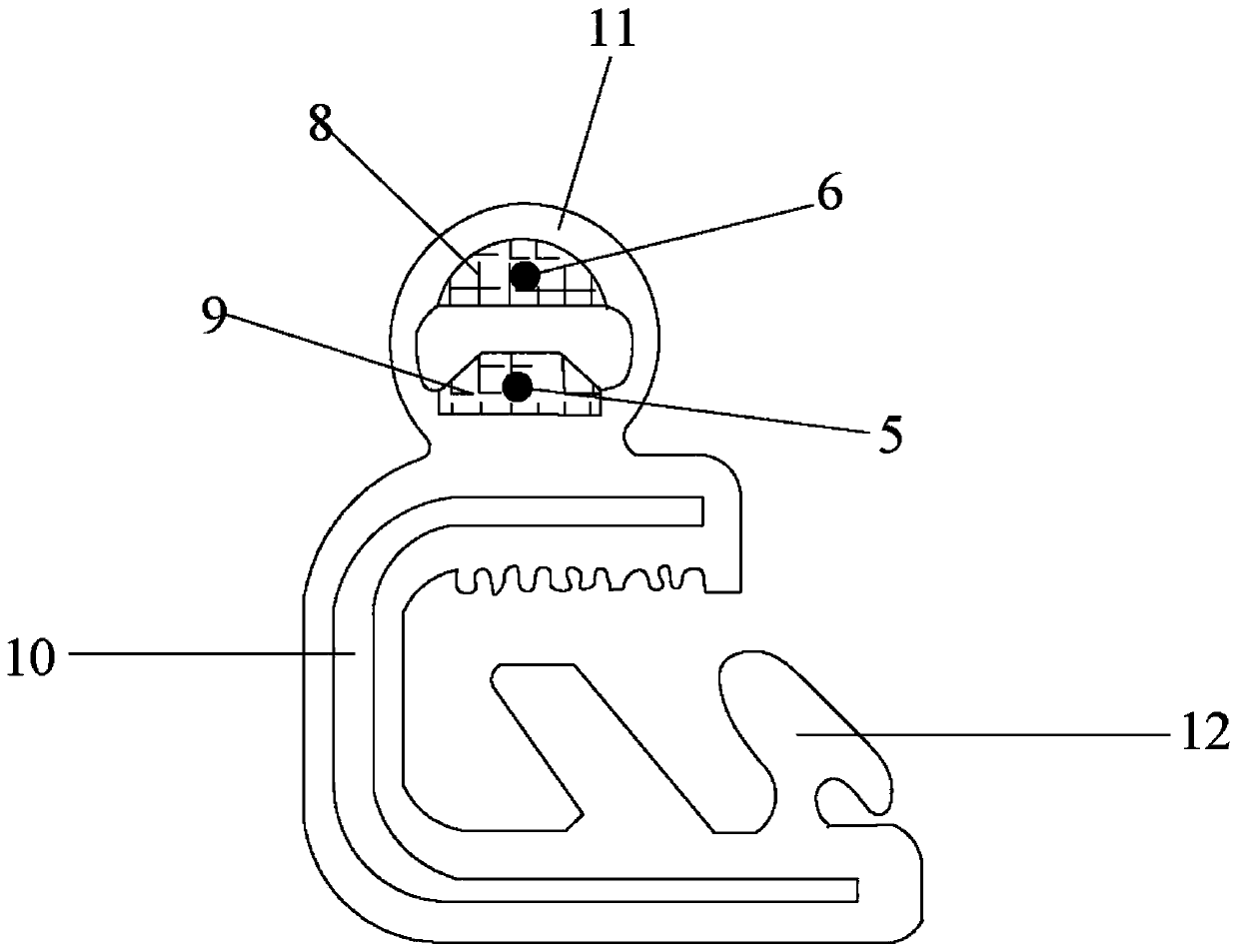

[0043] Please refer to figure 1 , with figure 1 It is a schematic diagram of the overall structure of an anti-skid and high-sensitivity automobile anti-pinch strip of the present invention.

[0044] An automobile anti-pinch strip with high sensitivity, comprising an anti-pinch strip body 1, both ends of the anti-pinch strip body 1 are sealed by injection molding, and a sensor harness, a harness buckle and a harness connector are also provided. The sensing harness is extended from one end of the anti-pinch strip body 1, the harness buckle is sleeved on the outside of the sensing harness, and the harness connector is installed on the free end of the sensing harness. The anti-pinch strip body 1 includes a sealing cover 2, a wire 3, and a wire opening 4, and the anti-pinch strip body 1 has a built-in conductor. Preferably, the sealing cover 2 is hollow inside.

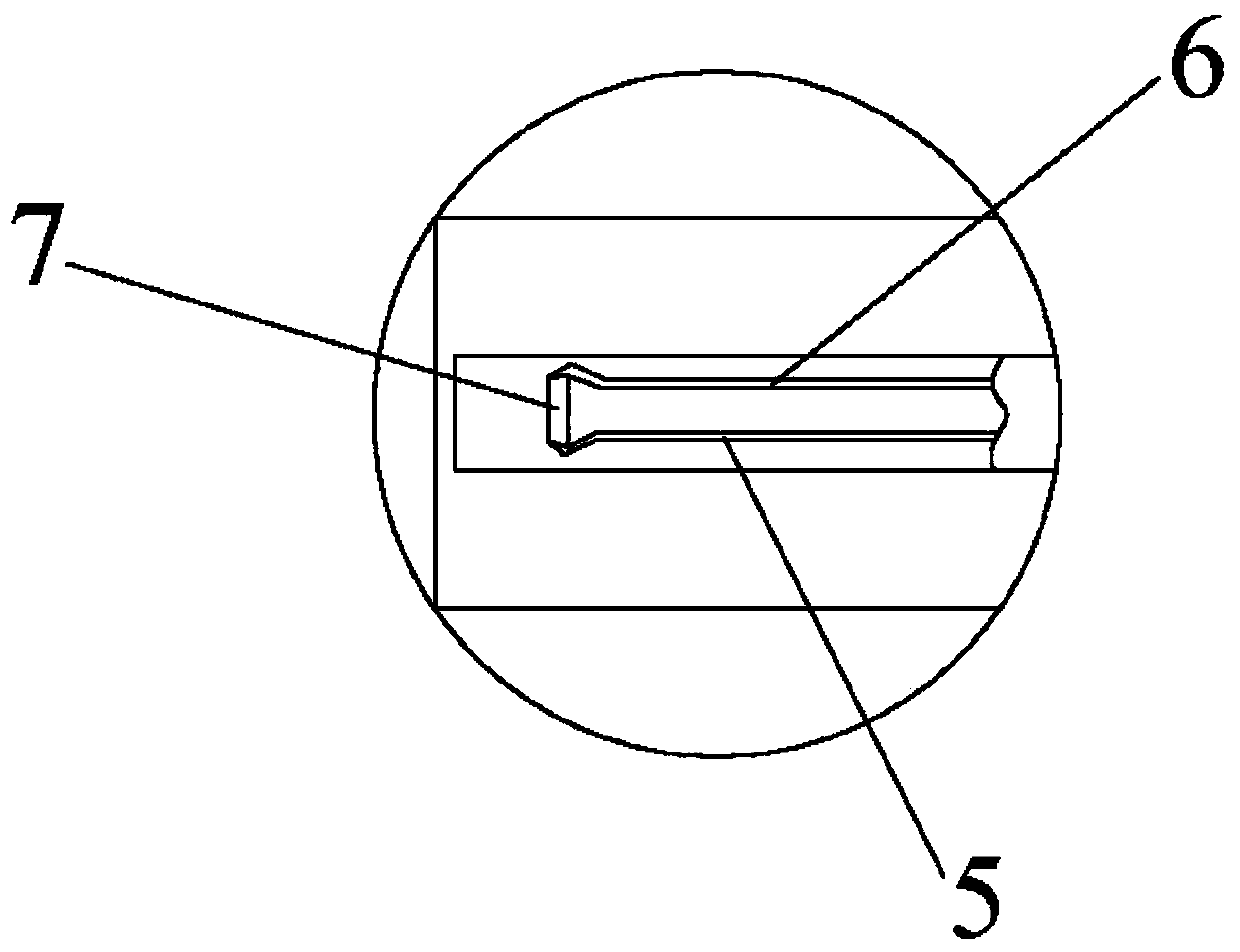

[0045] Please refer to figure 2 , with figure 2 yes figure 1 Schematic diagram of the enlarged structure inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com