Preparation method of flame-retardant low-odor wooden door coating

A low-odor, wooden door technology, applied in fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as easy combustion, and achieve the effects of promoting coverage, promoting dehydration and carbonization, and promoting charring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

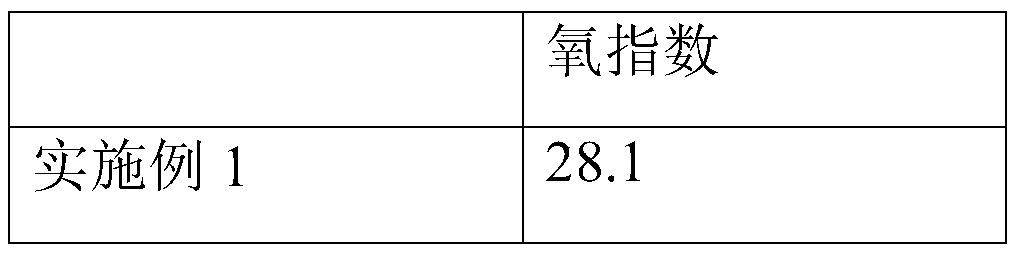

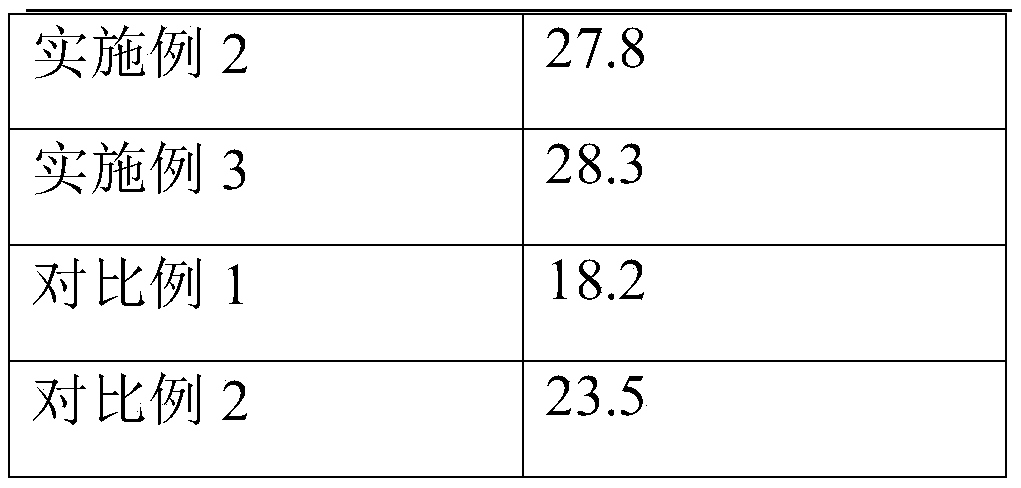

Examples

Embodiment 1

[0022] A kind of preparation method of flame-retardant low-odor wooden door coating, comprises the following steps:

[0023] (1) Add polyurethane emulsion, simethicone oil, and vinyl acetate emulsion to the reaction kettle in sequence, heat to 75°C, stir at 800r / min for 20min, and let stand for 1 hour to obtain a preparation;

[0024] (2) Evenly disperse diatomaceous earth into water glass, heat to 72°C, stir for 35 minutes to obtain a water glass mixture, then add ammonium phosphate and peroxide to the water glass mixture, and place in a water bath at 80°C Insulated and stirred for 40min, then rotated and evaporated, dried to constant weight to obtain diatomite composite material;

[0025] (3) Add hydroxymethyl cellulose to the mixed solution of sulfuric acid and phosphoric acid at a ratio of 100g: 150ml, stir and react for 30min at 35°C, then add melamine with 5% mass of hydroxymethyl cellulose, in an inert gas Under protection, continue to stir for 1 hour, ultrasonically d...

Embodiment 2

[0037] A kind of preparation method of flame-retardant low-odor wooden door coating, comprises the following steps:

[0038] (1) Add polyurethane emulsion, simethicone oil, and vinyl acetate emulsion to the reaction kettle in sequence, heat to 80°C, stir at 800r / min for 20min, and let stand for 1 hour to obtain a preparation;

[0039] (2) Evenly disperse diatomaceous earth into water glass, heat to 72°C, stir for 35 minutes to obtain a water glass mixture, then add ammonium phosphate and peroxide to the water glass mixture, and place in a water bath at 80°C Insulated and stirred for 40min, then rotated and evaporated, dried to constant weight to obtain diatomite composite material;

[0040] (3) Add hydroxymethyl cellulose to the mixed solution of sulfuric acid and phosphoric acid at a ratio of 100g: 180ml, stir and react for 35min at 35°C, then add melamine with 5% of the mass of hydroxymethyl cellulose, in an inert gas Under protection, continue to stir for 1 hour, ultrasoni...

Embodiment 3

[0052] A kind of preparation method of flame-retardant low-odor wooden door coating, comprises the following steps:

[0053] (1) Add polyurethane emulsion, simethicone oil, and vinyl acetate emulsion to the reaction kettle in sequence, heat to 78°C, stir at 800r / min for 20min, and let stand for 1 hour to obtain a preparation;

[0054] (2) Evenly disperse diatomaceous earth into water glass, heat to 72°C, stir for 35 minutes to obtain a water glass mixture, then add ammonium phosphate and peroxide to the water glass mixture, and place in a water bath at 80°C Insulated and stirred for 40min, then rotated and evaporated, dried to constant weight to obtain diatomite composite material;

[0055] (3) Add hydroxymethyl cellulose to the mixed solution of sulfuric acid and phosphoric acid at a ratio of 100g: 160ml, stir and react for 32min at 35°C, then add melamine with 5% mass of hydroxymethyl cellulose, in an inert gas Under protection, continue to stir for 1 hour, ultrasonically dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com