Method for producing crude white oil

A technology for white oil and products, applied in the treatment of hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc., can solve the problems of limited source of raw materials for white oil production, low impurity content, affecting process costs, etc., to broaden the source of raw materials, significantly The effect of economic benefits and high added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

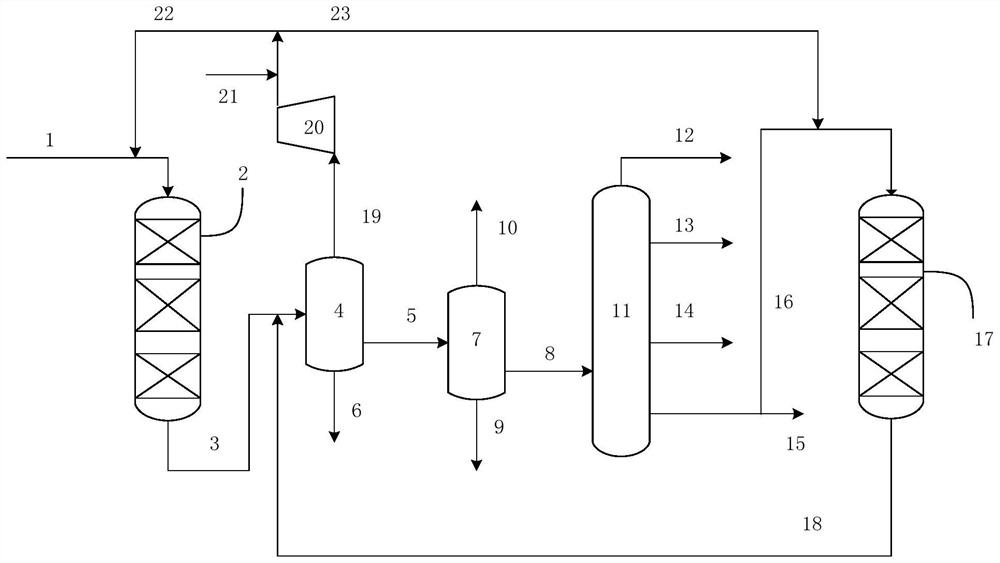

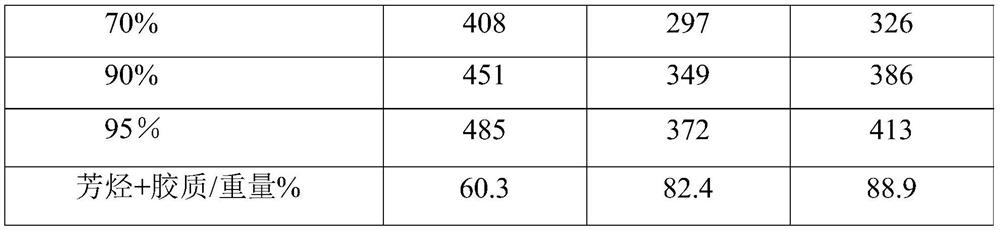

Embodiment 1

[0069] refer to figure 1 The flow shown processes coal tar fraction feedstock A. The raw material A first enters the hydrofinishing reaction zone and contacts with the hydrofinishing catalyst D to carry out the hydrofinishing reaction, and the hydrofinishing product is separated into naphtha (distillation range: <165°C), crude white oil (distillation range: 165-350°C ), and hydrogenated tail oil (initial boiling point is 350°C, aromatics content is 12.4% by weight). 90% by weight of the hydrogenated tail oil enters the hydrocracking reaction zone (the weight ratio of the hydrogenated tail oil entering the hydrocracking reaction zone to the raw material A is 1.7) contacts with the hydrocracking catalyst F to carry out the hydrocracking reaction, The hydrocracked product is mixed with the hydrorefined product for product separation. The obtained crude white oil was further fractionated to obtain No. 3 crude white oil and No. 5 crude white oil. The reaction conditions, product...

Embodiment 2

[0075] refer to figure 1 The flow shown processes coal tar fraction feedstock B. The raw material B first enters the hydrofinishing reaction zone and contacts with the hydrofinishing catalyst E to carry out the hydrofinishing reaction, and the hydrofinishing product is separated into naphtha (distillation range: <165°C), crude white oil (distillation range: 165-350°C ), and hydrogenated tail oil (initial boiling point is 350°C, aromatics content is 14.9% by weight). 75% by weight of the hydrogenated tail oil enters the hydrocracking reaction zone (the weight ratio of the hydrogenated tail oil entering the hydrocracking reaction zone to the raw material B is 1.3) and contacts with the hydrocracking catalyst F to carry out the hydrocracking reaction, The hydrocracked product is mixed with the hydrorefined product for product separation. The obtained crude white oil was further fractionated to obtain No. 3 crude white oil and No. 5 crude white oil. The reaction conditions, pro...

Embodiment 3

[0077] refer to figure 1 The process shown processes the coal tar fraction feedstock C. The raw material C first enters the hydrofinishing reaction zone and contacts with the hydrofinishing catalyst E to carry out the hydrofinishing reaction, and the hydrofinishing product is separated into naphtha (distillation range: <165°C), crude white oil (distillation range: 165-350°C ), and hydrogenated tail oil (initial boiling point is 350°C, aromatics content is 13.6% by weight). 99% by weight of the hydrocracking tail oil enters the hydrocracking reaction zone (the weight ratio of the hydrogenation tail oil entering the hydrocracking reaction zone to the raw material C is 1.5) contacts with the hydrocracking catalyst G to carry out the hydrocracking reaction, The hydrocracked product is mixed with the hydrorefined product for product separation. The obtained crude white oil was further fractionated to obtain No. 3 crude white oil and No. 5 crude white oil. The reaction conditions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com