Crystal pulling growth device

A growth device and crystal technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of thermal distribution asymmetry, crystal quality influence, strict equipment requirements, etc., to reduce the probability of seed crystal fracture, improve Good crystal growth quality and thermal distribution symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

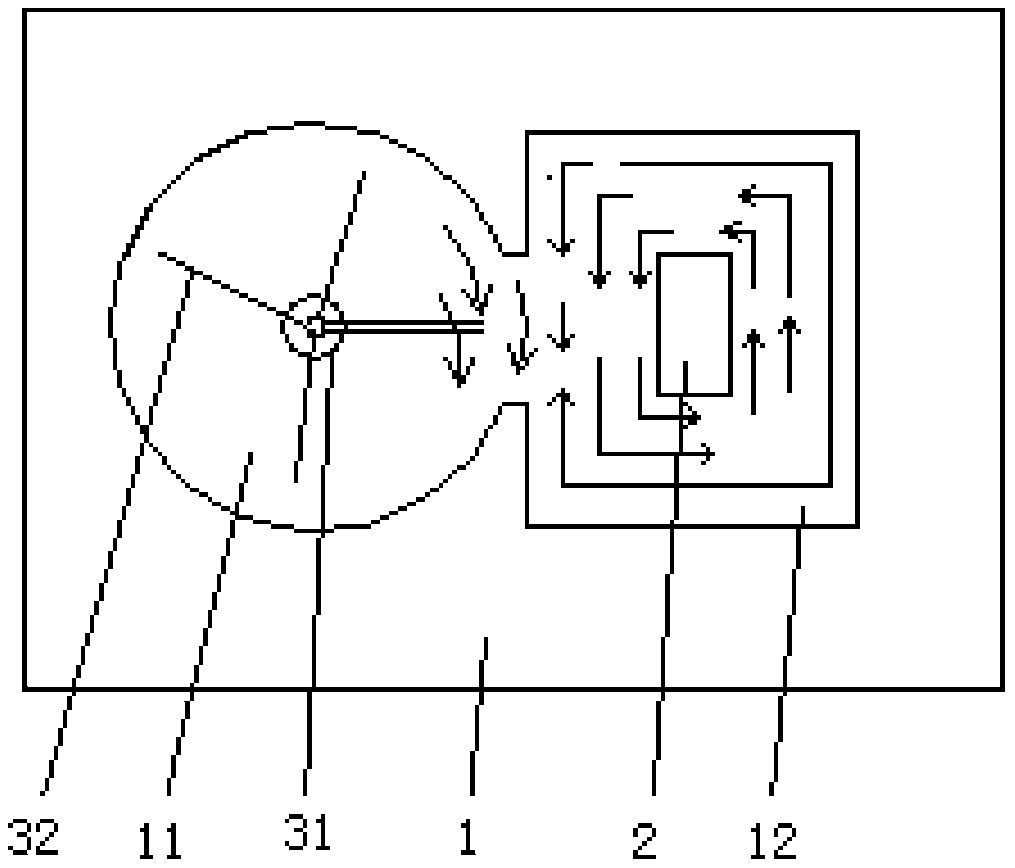

[0032] Such as figure 1 As shown, the crystal pulling growth device of the present invention is applied to contain polycrystalline melts to grow rectangular crystals 2 by pulling method, and it includes a main body 1 made of platinum material, and the main body 1 is provided with a multi- The stirring chamber 11 of the crystal melt, the cross section of the stirring chamber 11 is circular, and one side of the stirring chamber 11 is connected with a growth chamber 12 with a rectangular cross section, and the polycrystalline melt in the stirring chamber 11 is controlled by an external The platinum stirring rod 31 is rotated and stirred to drive the polycrystalline melt in the growth chamber 12 to form a rectangular circulation for growing the rectangular crystal 2 by the pulling method.

[0033] The crystal pulling growth device of the present invention is applied to a polycrystalline melt to carry out a method for growing a KTN crystal by a pulling method comprising the followi...

Embodiment 2

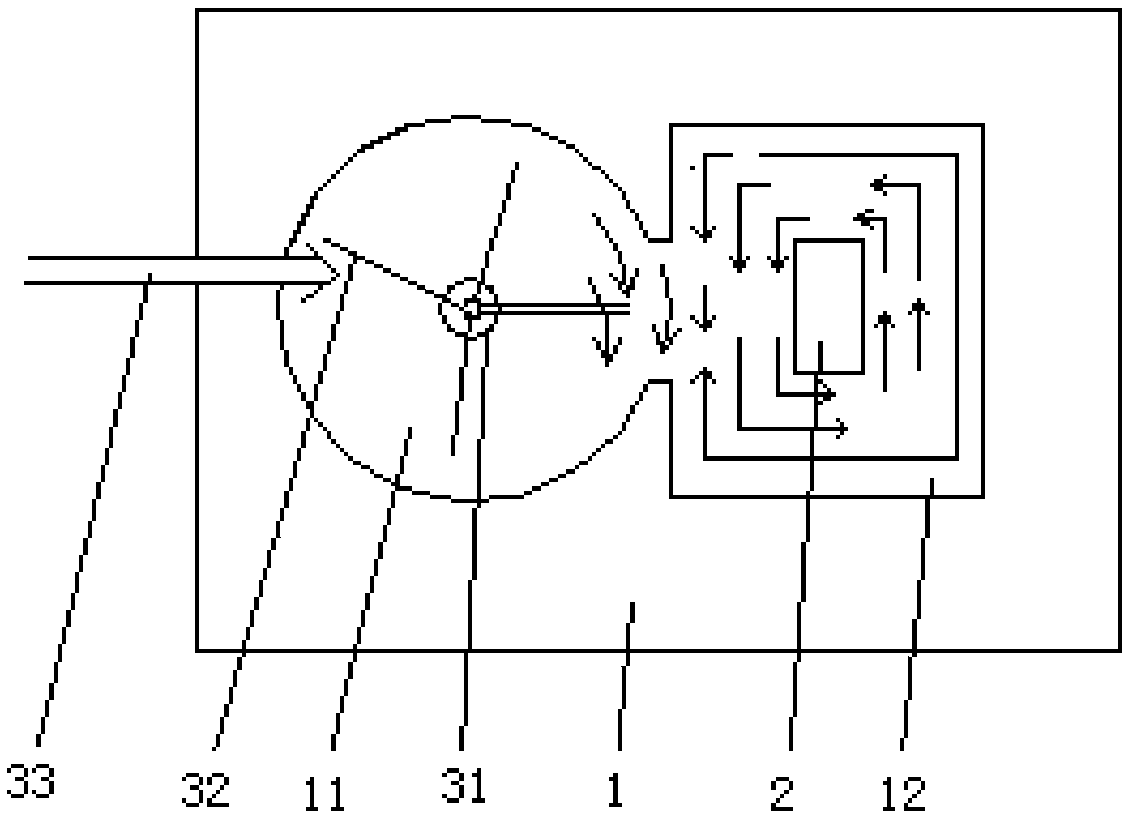

[0040] Such as figure 2 As shown, on the basis of the structure of the crystal pulling growth device described in Example 1, when an automatic feeding device 33 is provided in the muffle furnace, it is also possible to prepare KTN polycrystalline feedstock for feeding;

[0041] The preparation method of KTN polycrystalline supplementary material is as follows: according to the molar ratio of 1.02:0.37:0.63, weigh the raw material K 2 CO 3 , Nb 2 o 5 and Ta 2 o 5 Grind in a mortar and mix well, then use 10 8 Pa is pressurized to make block raw materials, and then put the block raw materials in a traditional platinum crucible, put them into the heating chamber of the muffle furnace, and slowly raise the temperature to 1100 °C at a heating rate of 5-60 °C / h, and keep the temperature for 48 hours. Get KTN polycrystalline feed;

[0042] The present invention adopts the above technical scheme, during the crystal growth period, the KTN polycrystalline feed material is quantit...

Embodiment 3

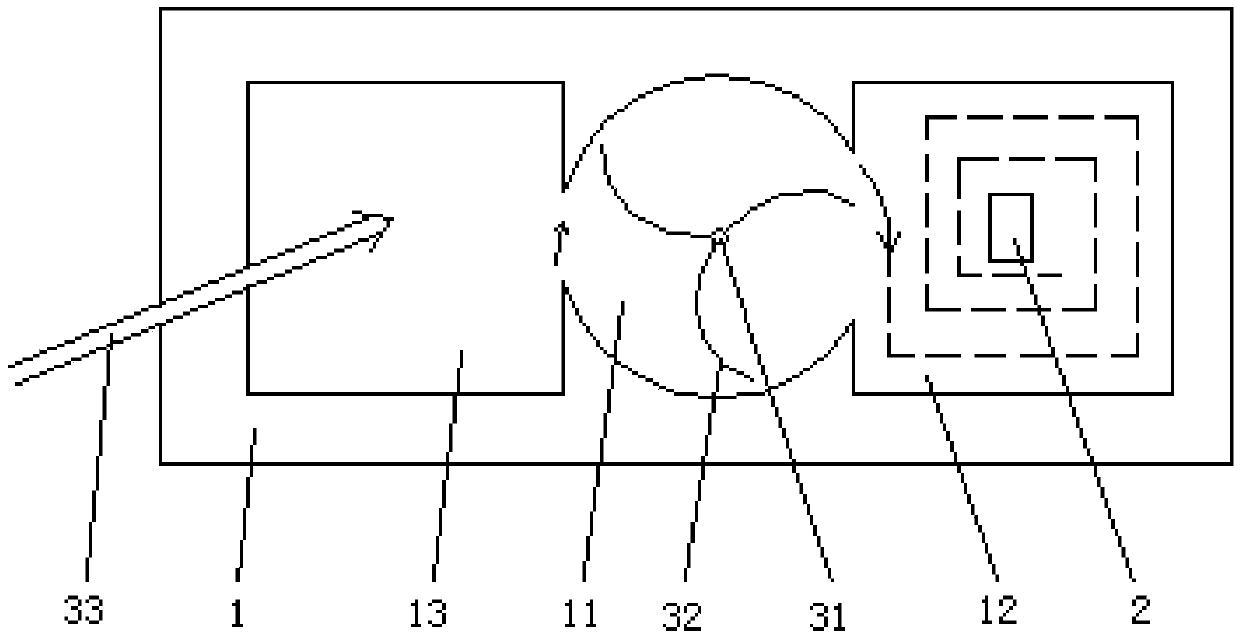

[0044] Such as image 3 As shown, on the basis of the structure of the crystal pulling and growing device described in Embodiment 2, a feeding chamber 13 for feeding polycrystalline melt is connected to the other side of the stirring chamber 11 .

[0045] Preferably, the cross section of the feeding chamber 13 is rectangular or circular.

[0046] The present invention adopts the above technical scheme, which can overcome the requirement of fast melting speed of feeding materials directly into the stirring chamber 11, and reduces the technical difficulty of feeding materials. When the muffle furnace is provided with an automatic feeding device 33, it is also possible to prepare the KTN polycrystalline feed material according to the preparation method described in embodiment 2, and during crystal growth, the KTN polycrystalline feed material is fed from the KTN polycrystalline feed device 33 by the automatic feeding device 33. The upper part is quantitatively fed into the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com