Method for reducing dicing crushing rate of traditional Chinese medicine raw materials

A crushing rate and dicing technology, which is applied in the direction of progressive dryers, dryers, metal processing, etc., can solve the problems of high dicing broken rate, low dicing efficiency, time-consuming and labor-intensive, etc., to reduce the broken rate, Improve dicing efficiency and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In the present embodiment, a method for reducing the broken rate of diced Chinese medicine raw materials is proposed, including the following steps:

[0053] Step 1: first use a slicing device to slice the raw materials of traditional Chinese medicine;

[0054] Step 2: Use the conveyor belt to transport the sheet-shaped medicinal materials cut by the slicing device to the drying unit, and the drying unit performs dehydration treatment on the sheet-shaped medicinal materials;

[0055] Step 3: Use a dicing device to dice the dried sheet medicinal materials on the conveyor belt.

[0056] Through the above steps, it is possible to realize the continuous slicing and dicing processing of traditional Chinese medicine raw materials. Before dicing, the drying unit is used to dry the sheet-shaped medicinal materials on the conveyor belt, so that the surface of the sheet-shaped medicinal materials is dry. The dicing device When dicing the dried sheet-like medicinal materials on t...

Embodiment 2

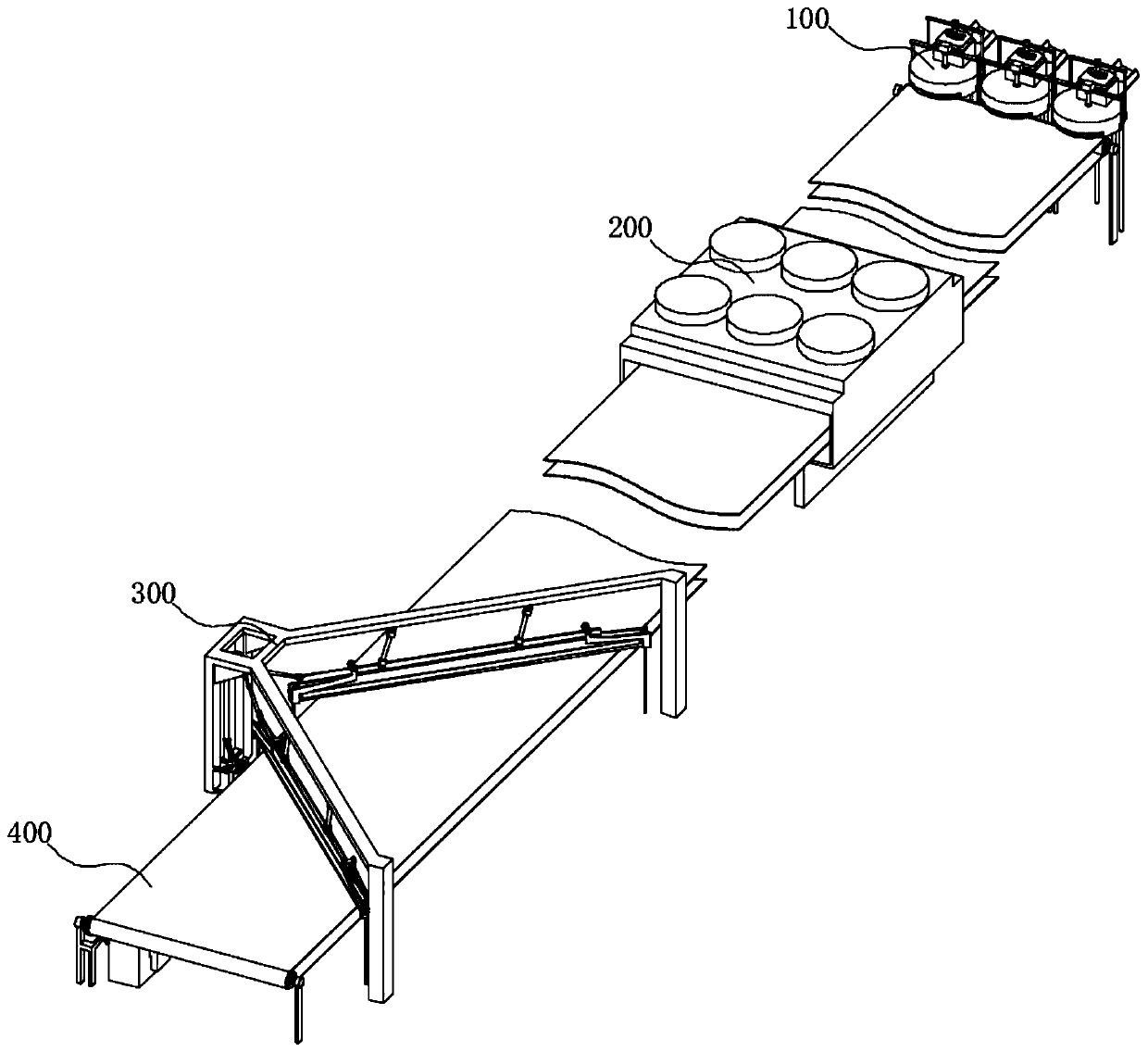

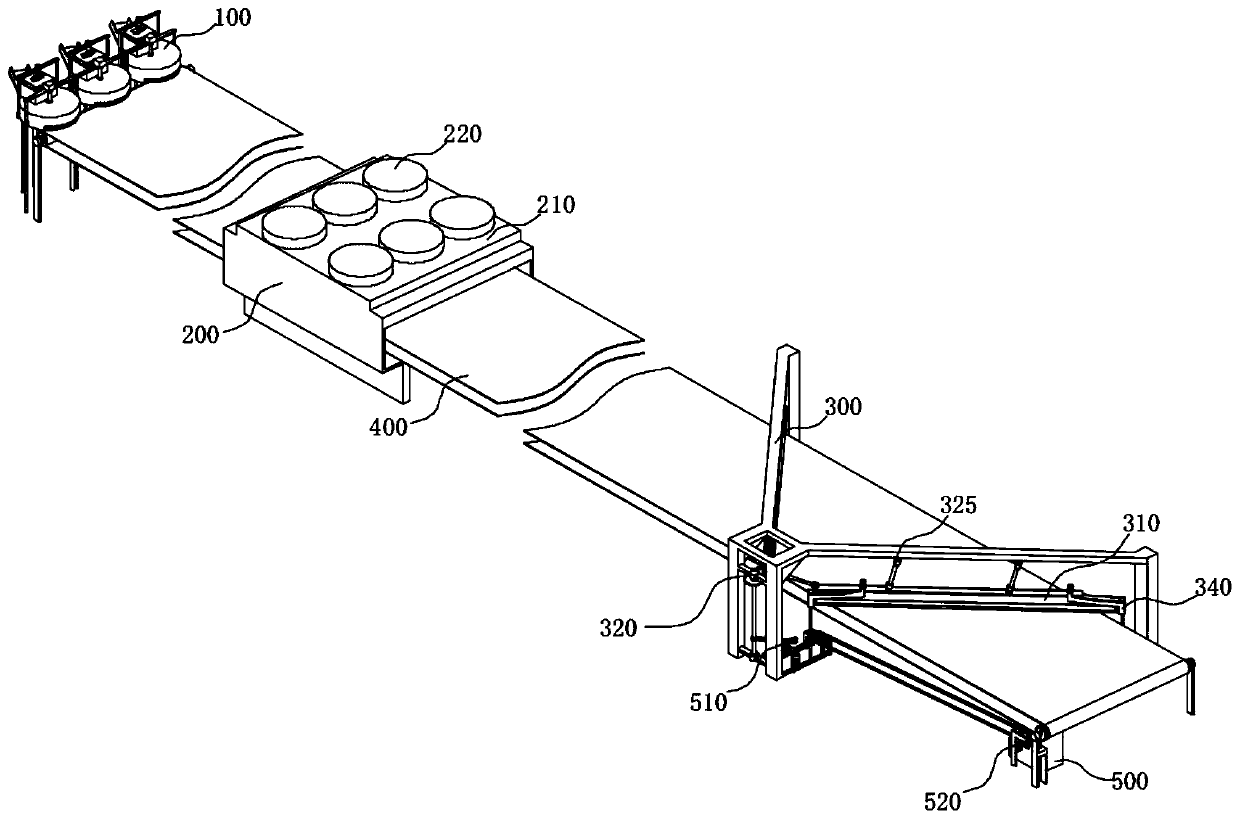

[0086] refer to Figure 1-4 , 10. In this embodiment, a system for improving the dicing efficiency of Chinese medicine raw materials is proposed, including a conveyor belt 400. The feeding end of the conveyor belt 400 is equipped with a slicing unit for slicing the Chinese medicine raw materials. There is also a drying unit 200 for drying the sheet-like medicinal materials, and a dicing device 300 for dicing the sheet-like medicinal materials.

[0087] Through the setting of the slicing unit, the traditional Chinese medicine raw materials are first cut into slices, and the sheet-shaped medicinal materials are transported through the drying unit 200 through the setting of the conveyor belt 400, and the drying unit 200 performs dehydration treatment on the sheet-shaped medicinal materials, so that the sheet-shaped medicinal materials The surface is dry, and when the conveyor belt 400 transports the surface-dried medicinal material through the dicing device 300, the dicing device...

Embodiment 3

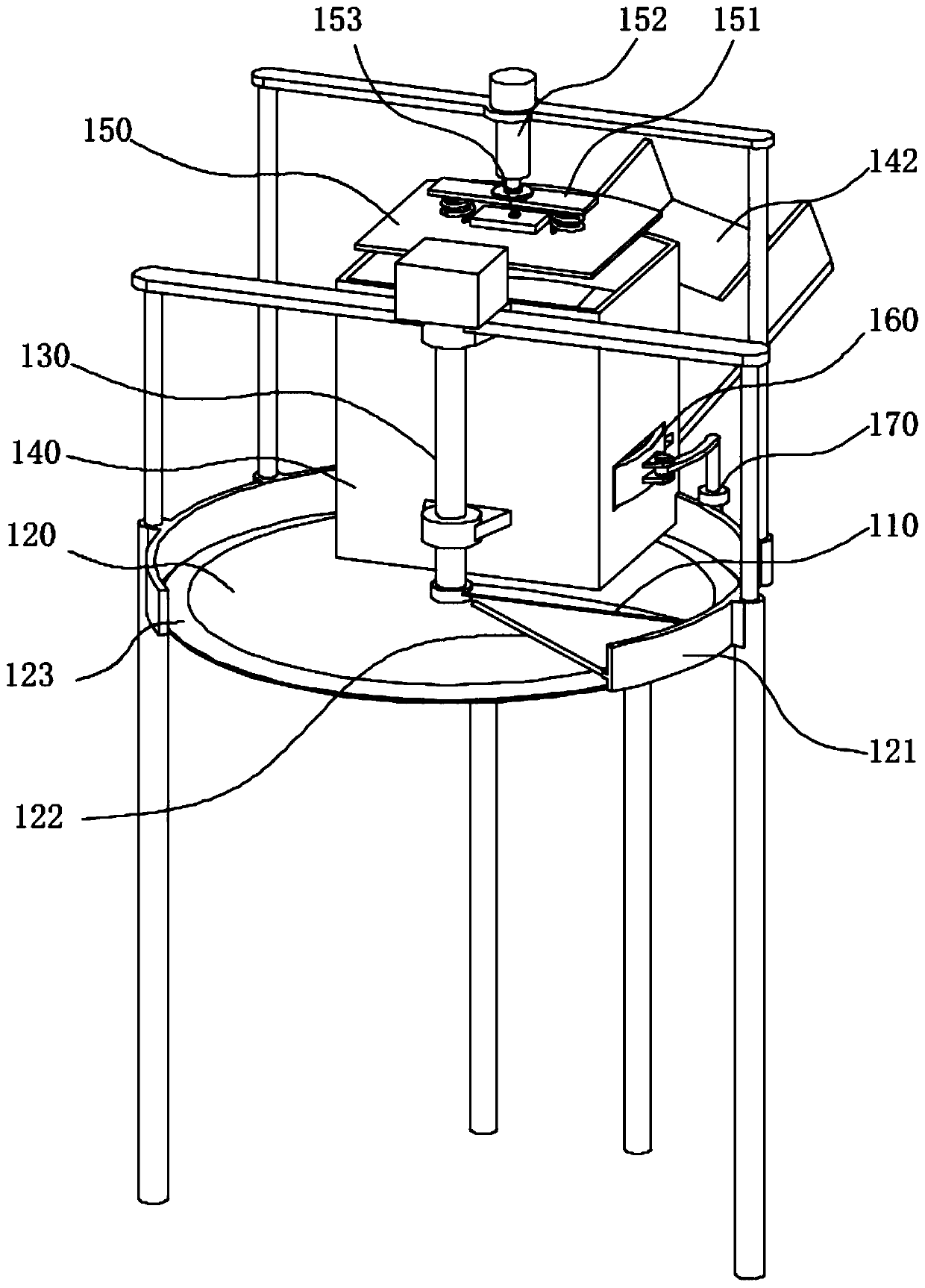

[0109] refer to Figure 3-8 , according to the present invention, in this embodiment, a Chinese medicine raw material slicing device is proposed, including a frame, a conveyor belt is installed on the frame, and a hopper 140 for constraining the horizontal movement of the medicinal material is installed at the feeding end of the conveyor belt, and the lower end of the hopper 140 is There is an opening for the medicinal material to drop, and the lower end of the hopper 140 is provided with a slicing knife 110 and a material supporting surface arranged at intervals up and down. The thickness of the slices is the same, the supporting surface is used to support the medicinal materials, the slicing knife 110 is connected to the driving mechanism with the supporting surface, and the driving mechanism is used to drive the slicing knife 110 and the supporting surface to move horizontally, and the slicing knife 110 moves horizontally to slice the medicinal materials. The horizontal mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com