Device for recycling leftover rubber in production process of sealing parts and utilizing method of device

A recycling device and leftover technology, applied in recycling technology, plastic recycling, mechanical material recycling, etc., can solve the problems of unfavorable work efficiency, large space occupation, unfavorable storage, etc., and achieve the effect of convenient implementation, space saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

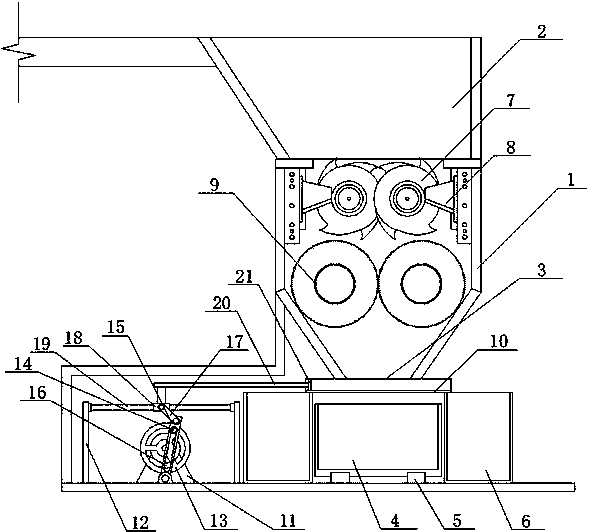

[0024] see figure 1 , the present invention provides a technical solution: a scrap rubber recovery device in the process of producing seals, comprising a housing 1, the upper end of the housing 1 is provided with a material inlet 2, the upper end of the housing 1 is fixedly connected with the workbench, and the feeding A shredding device, a powder milling device and a screening device are provided in sequence below the port 2, a discharge port 3 is provided below the powder milling device, a collection box 4 is provided below the discharge port 3, and the bottom end of the collection box 4 is slidingly connected There are slide rails 5, and both sides of the collection box 4 are provided with waste bins 6.

[0025] Wherein, tearing device comprises two groups of knife rollers 7, and the two sides of two groups of knife rollers 7 are alternately provided with blade 8, and blade 8 is fixedly connected on the inner wall surface of housing 1, and guide roller 7 is connected with e...

Embodiment 2

[0029] A method for utilizing a leftover rubber recovery device in the process of producing seals, comprising the following specific implementation steps:

[0030] Step 1: drive the cutter roller 7 and grinding roller 9 to operate through an external motor, and set the rotation speed of the cutter roller 7 and grinding roller 9, and at the same time drive the runner 13 to rotate through an external motor, so that the connecting rod 20 drives the push plate 21 on the screen The upper end surface of the plate 10 reciprocates;

[0031] Step 2, sending scraps produced during the production of the seal into the material inlet 2 from the surface of the workbench;

[0032] Step 3, the leftover material enters the guide roller 7, and the rotating knife claws bring the leftover material between the two sets of knife rollers 7, and the leftover material is cut and shredded by the rotating knife roller 7, and then enters between the two sets of grinding rollers 9, Two groups of grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com