Surface treatment method for preventing rubber product from blooming

A technology for rubber products and surface treatment, applied in the field of rubber product production, can solve the problems of high cost, complicated process and poor anti-frost effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

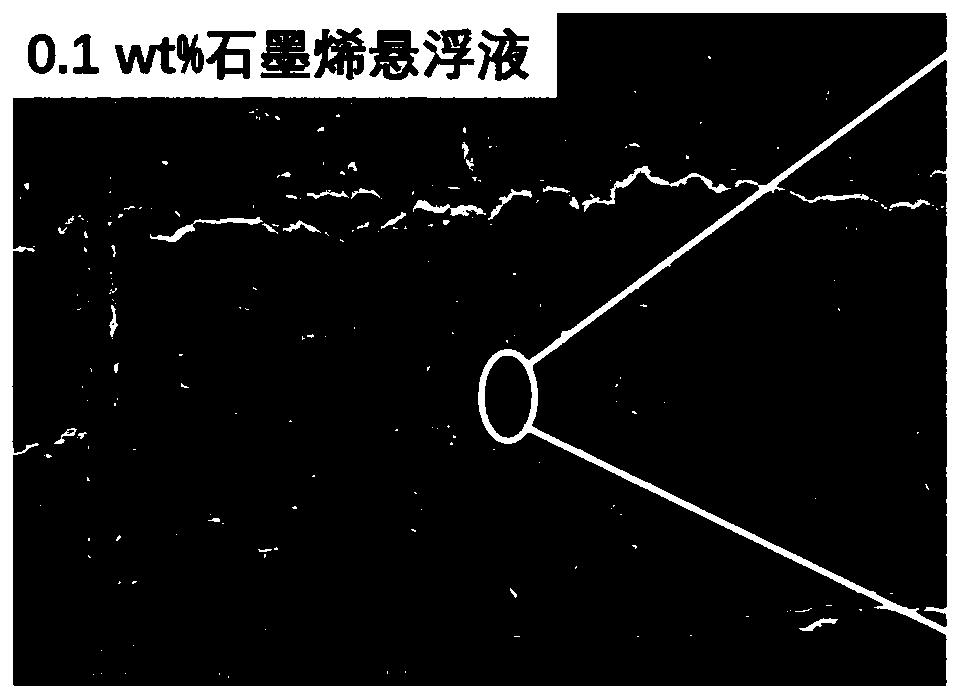

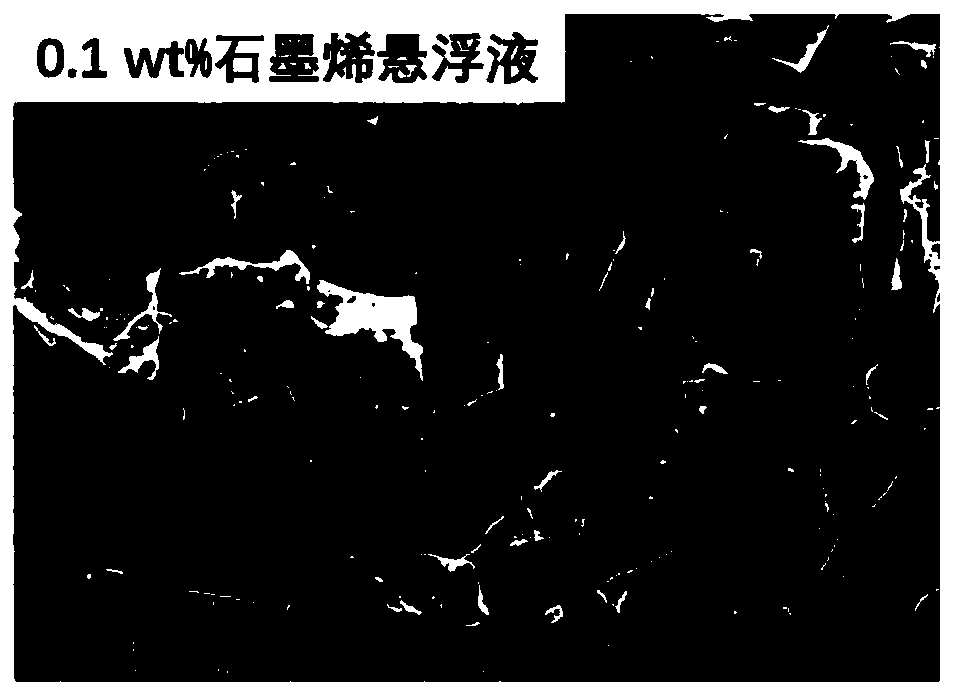

[0048] Take a cured natural rubber glove from the natural rubber glove preparation workshop, cut 4 finger cots on the glove, use 95% ethanol to scrub the surfaces of the 4 finger cots, rinse them with water, and then dry them. Prepare 200mL of A171 (vinyltrimethoxysilane) solution with a concentration of 1wt% (solvent is alcohol: water volume = 5:5), and prepare three different specifications of oxidation 150 mL each of the graphene suspensions. The graphene oxide in the graphene oxide suspensions of three specifications was prepared from the same batch of hummer's method.

[0049] Use tweezers to dip the four finger cots into the A171 solution for 4-5 seconds, take them out, and place them together in an oven at 60°C for drying. Take it out after drying, and then use tweezers to pick up three of the finger cots and then dip them into the graphene oxide suspensions with concentrations of 0.01wt%, 0.05wt%, and 0.1wt%, respectively, and completely impregnate the 4- Take it out...

Embodiment 2

[0054] Take a natural rubber glove with cured rubber from the natural rubber glove preparation workshop, cut a finger cot from the glove, scrub the surface of a finger cot with 95% ethanol and rinse with water, and then dry it.

[0055] Prepare 200mL of A151 (vinyltriethoxysilane) solution with a concentration of 1.5wt% (solvent is alcohol: water volume = 5:5), and prepare 150mL of graphene oxide suspension with a concentration of 0.1wt%. Among them, graphene oxide comes from hummer's method.

[0056] Use tweezers to dip the cut finger cot into the A151 solution for 4-5 seconds, take it out, and place it in an oven at 60°C to dry. Take it out after drying, then pick up the finger cot with a nickel and turn it into a graphene oxide suspension with a concentration of 0.1wt%, take it out after completely soaking for 4-5s, and place it in an oven at 120°C for drying ,take out. Stir and wash in 200mL deionized water three times, then dry at 100°C.

[0057] Place the finger cot u...

Embodiment 3

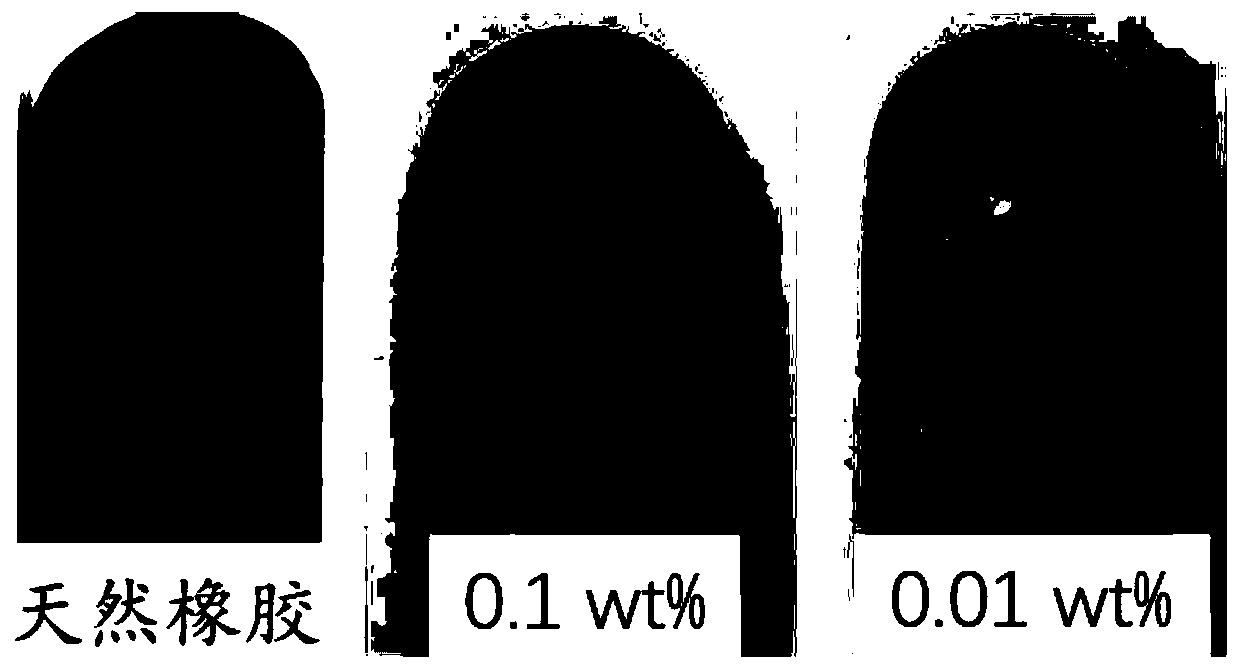

[0059] Take a cured natural rubber glove from the natural rubber glove preparation workshop (add black color paste to make a pure black glove), cut 3 finger cots on the glove, and put the 3 finger cots Surfaces were scrubbed with 95% ethanol and rinsed with water and then dried.

[0060] The preparation concentration is 200mL of A171 (vinyltrimethoxysilane) solution of 2wt% (solvent is alcohol: water volume = 5:5), and the preparation concentration is 0.01wt%, 0.1wt% two specifications of graphene oxide suspension respectively 200mL. The graphene oxide in the graphene oxide suspension used was prepared from the same batch of hummer's method.

[0061] Use tweezers to dip the three finger cots into the A171 solution for 4-5 seconds, take them out, and place them together in an oven at 60°C for drying. Take it out after drying, then pick up two of the finger cots with a nickel and dip them in the graphene oxide suspension with a concentration of 0.01wt% and 0.1wt%, respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com