Method for Reconstructing Powder Resin to Form Floc Resin to Remove Nitrate in Water

A technology of powder resin and water removal, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. It can solve the problems of non-adsorption, difficulty in popularization, and secondary pollution of water bodies, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

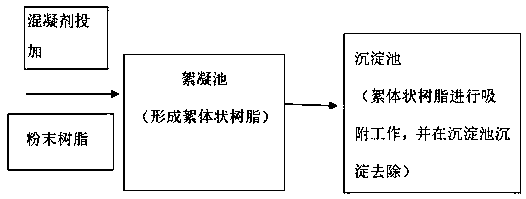

[0029] A method for reconstitution of powder resin to form floc resin to remove nitrate in water, characterized in that it comprises the following steps:

[0030] Step 1: Detect nitrate content in water;

[0031] Step 2: If the nitrate content exceeds the standard, then dosing powder resin while adding coagulant to the flocculation tank, so that the coagulant and powder resin are reconstituted to form resin flocs, the particle size of the powder resin It is 50-100 micron, and described coagulant is iron salt coagulant and / or aluminum salt coagulant; Mixing with the coagulant in the aqueous solution is conducive to the complete reconstitution of the powder resin and the coagulant to form resin flocs, preventing the unreconstructed powder resin from remaining in the water.

[0032] The powder resin is an anionic resin containing a basic group, and the basic group includes but is not limited to: —N(CH 3 ) 3 OH, -NH 2 ,—NH 2 , the reconstruction method of the structure of the...

Embodiment 2

[0038] A method for removing nitrate in water by reconstitution of powder resin to form floc resin, comprising the following steps: detecting the content of nitrate in water;

[0039] If the nitrate content exceeds the standard, then add the powdered resin while adding the coagulant to the flocculation tank, so that the coagulant and the powdered resin are reconstituted to form resin flocs, and the particle size of the powdered resin is 50- 100 microns, the powder resin is an anionic resin containing basic groups, the basic groups include but not limited to: —N(CH 3 ) 3 OH, -NH 2 ,—NH 2 , the reconstruction method of the structure of the resin by using the coagulant is adsorption neutralization and / or adsorption bridging. As a preference, before adding the powder resin while adding the coagulant to the flocculation tank, mix the powder resin with the mixture The coagulant is mixed in the aqueous solution. Specifically, the feeding pipe of the flocculant dosing device of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com