Hydrotreating method of chlorine-containing waste animal and plant oil

A technology for waste animal and plant and hydrotreating, which is applied in the field of hydrotreating chlorine-containing waste animal and plant oil, can solve problems such as corrosion of equipment, pipelines, and safety hazards, and achieve the effects of reducing corrosion, improving quality, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

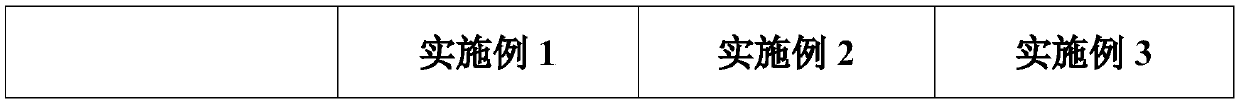

Examples

Embodiment Construction

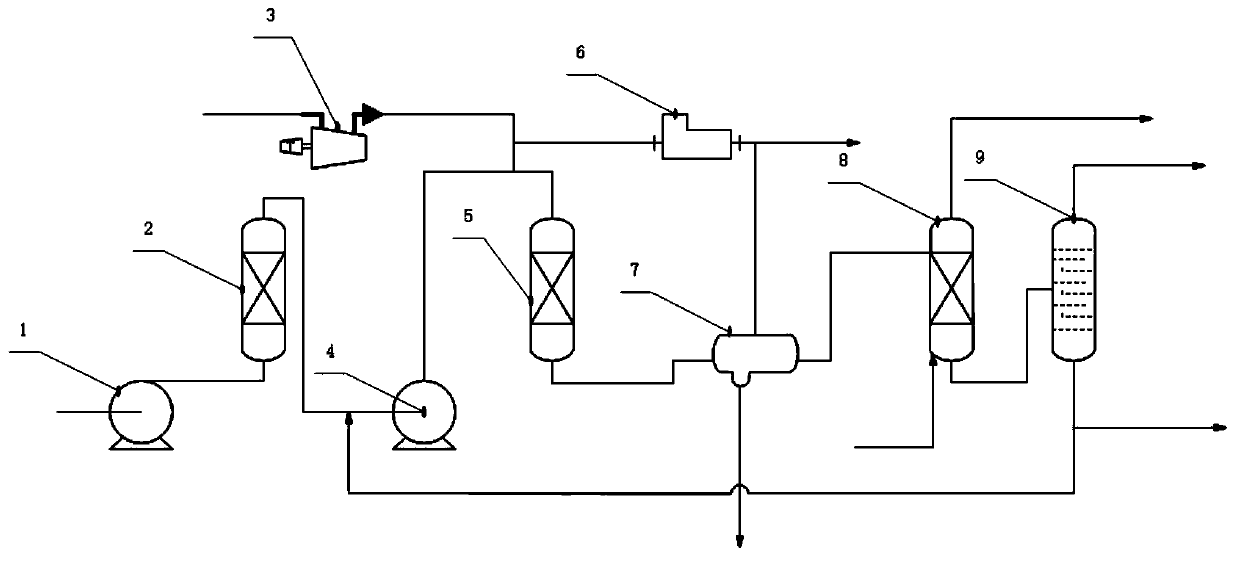

[0022] The method of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereby.

[0023] A method for hydrogenation treatment of chlorine-containing waste animal and vegetable oils, the steps of which are:

[0024] a) Put the waste animal and vegetable oils into the dechlorination tower 2 through the A feed pump 1, and carry out the dechlorination reaction in the presence of the dechlorination agent; the reaction conditions of the dechlorination reaction are: liquid space velocity 2~8h -1 , the dechlorination temperature is 200~280℃;

[0025] b) In step a) the dechlorinated material is uniformly mixed with an environmentally friendly liquid paraffin to obtain a mixture; wherein, the environmentally friendly liquid paraffin accounts for 10wt.% to 90wt.% of the dechlorinated material in step a);

[0026] c) The mixture obtained in step b) is added to the hydrofinishing reactor 5 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com